CVT SYSTEM

3-37

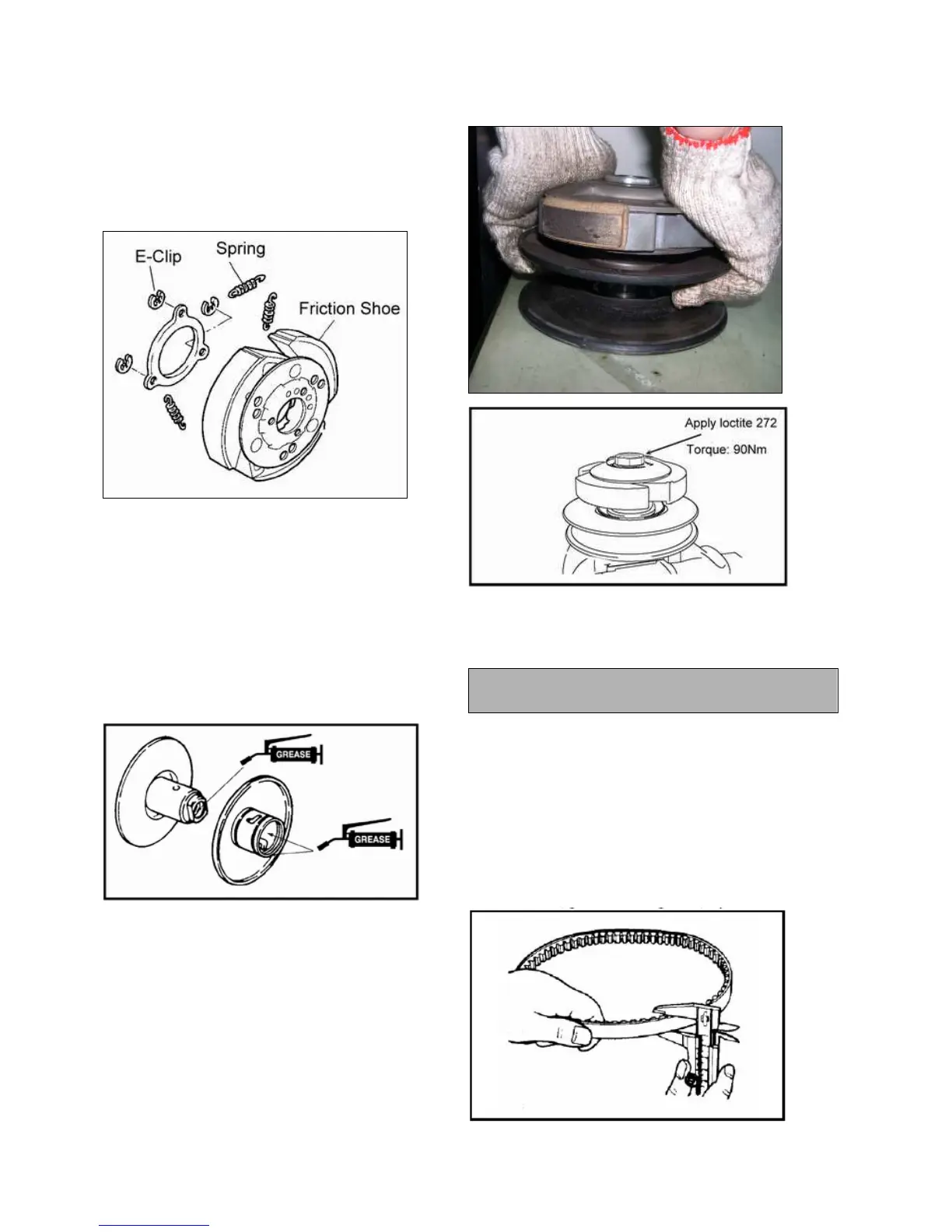

6. To replace the friction shoes, remove the e—clips that

retain the backing plate. Use a suitable tool to remove and

install the springs connecting the shoes, using care not to

over--stretch the springs more than is necessary.

DRIVEN CLUTCH ASSEMBLY

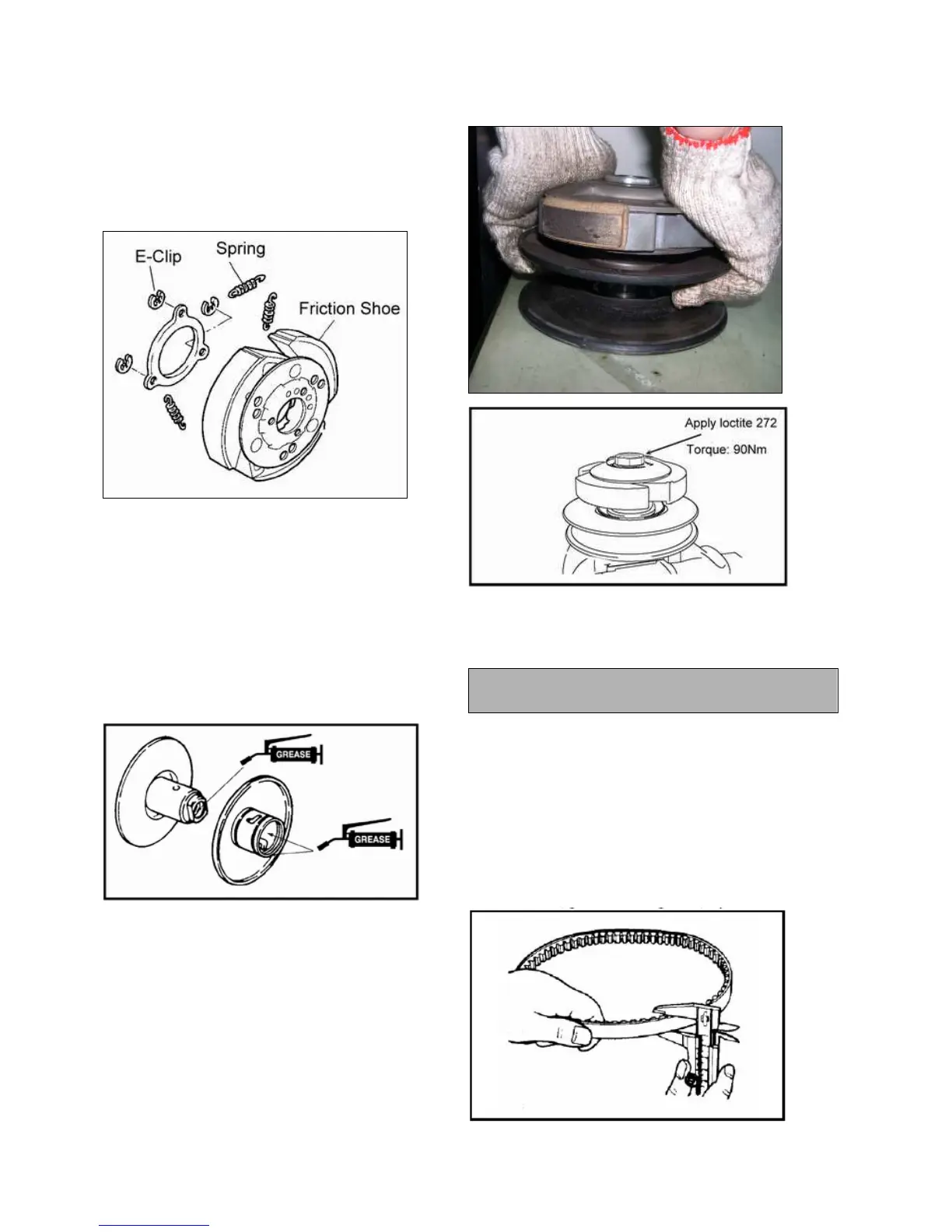

1. Insert new seals into the outer sheave assembly. Fill the

outer sheave cavity with fresh grease and slide onto the

sheave shaft. Align and insert the roller/pin

Install new o-rings and the outer roller pin

washer onto the threaded shaft and apply

threads.

2. Have an assistant available for final assembly.

Install the compression spring. Place the friction

assembly over the spring and compress the

together with both hands. With

the assembly compressed and

the threads exposed, have an assistant thread a new

nut onto the shaft. Secure the assembly

and torque the retaining nut to 90 Nm.

NOTE: Outer sheave retaining nut replacement is

strongly recommended. Use Loctite 272 on the

threads during reassembly.

Driven Assembly Nut Torque

90 Nm (67 ft. lbs.)

CVT Belt Inspection

3. Inspect the surface of the drive belt for uneven wear or

grease deposits. Using a caliper, measure the width of the belt.

The service limit of the belt is 24 mm. If the width of the belt

is less than the service limit, or if the belt is worn, glazed or

hour--glassed, replace.

Loading...

Loading...