ENGINE

4-64

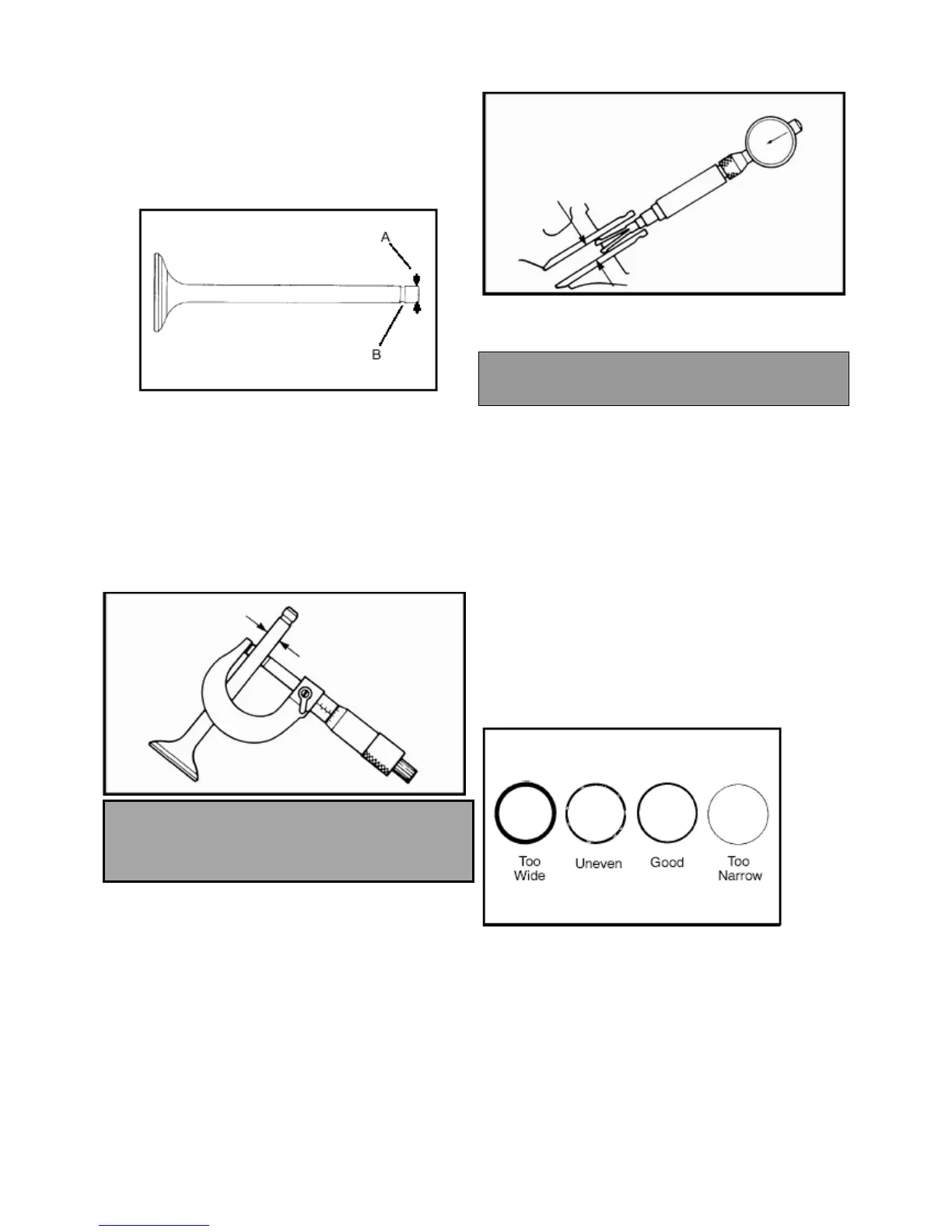

3. To check for bent valve stems, mount valve in a drill or use

“V” blocks and a dial indicator.

4. Check end of valve stem for flaring, pitting, wear or damage

(A).

5. Inspect split keeper groove for wear or flaring of the keeper

seat area (B).

NOTE: The valves cannot be re-faced or end ground.

They must be replaced if worn, bent, or damaged.

6. Measure diameter of valve stem with a micrometer in three

places and in two different directions (six measurements total).

Replace if excessive wear is evident.

Valve Stem OD LIMIT:

Intake Valve Limit: 4.975mm

Exhaust Valve Limit: 4.955mm

7. Measure valve guide inside diameter at the top middle and

end of the guide using a small-hole gauge and a micrometer.

Measure in two directions, front to back and side to side.

8. Subtract valve stem measurement to obtain stem to guide

clearance.

Stem-to-guide clearance

Limit >: 0.10mm

NOTE: Be sure to measure each guide and valve

combination individually.

9. Replace valve and/or guide if clearance is excessive.

NOTE: If valve guides are replaced, valve seats must

be reconditioned. Refer to Valve Seat Reconditioning

for procedure.

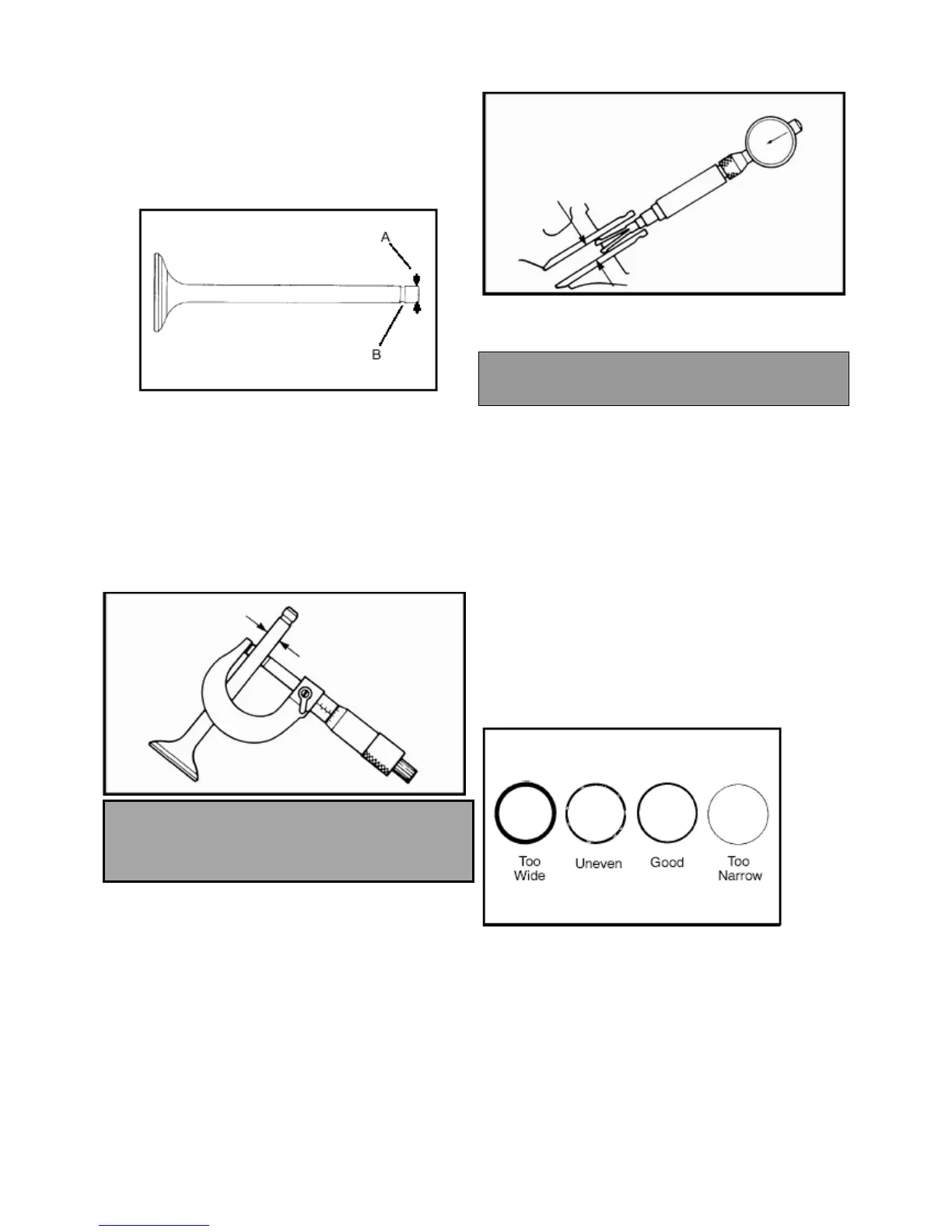

VALVE SEAT RECONDITIONING

Valve Seat Inspection

Inspect valve seat in cylinder head for pitting, burnt spots,

roughness, and uneven surface. If any of the above conditions

exist, the valve seat must be reconditioned. If the valve seat is

cracked the cylinder head must be replaced.

CYLINDER HEAD RECONDITIONING

NOTE: Servicing the valve guides and valve seats

requires special tools and a thorough knowledge of

reconditioning techniques. Follow the instructions

provided in the Valve Seat Reconditioning Kit.

Loading...

Loading...