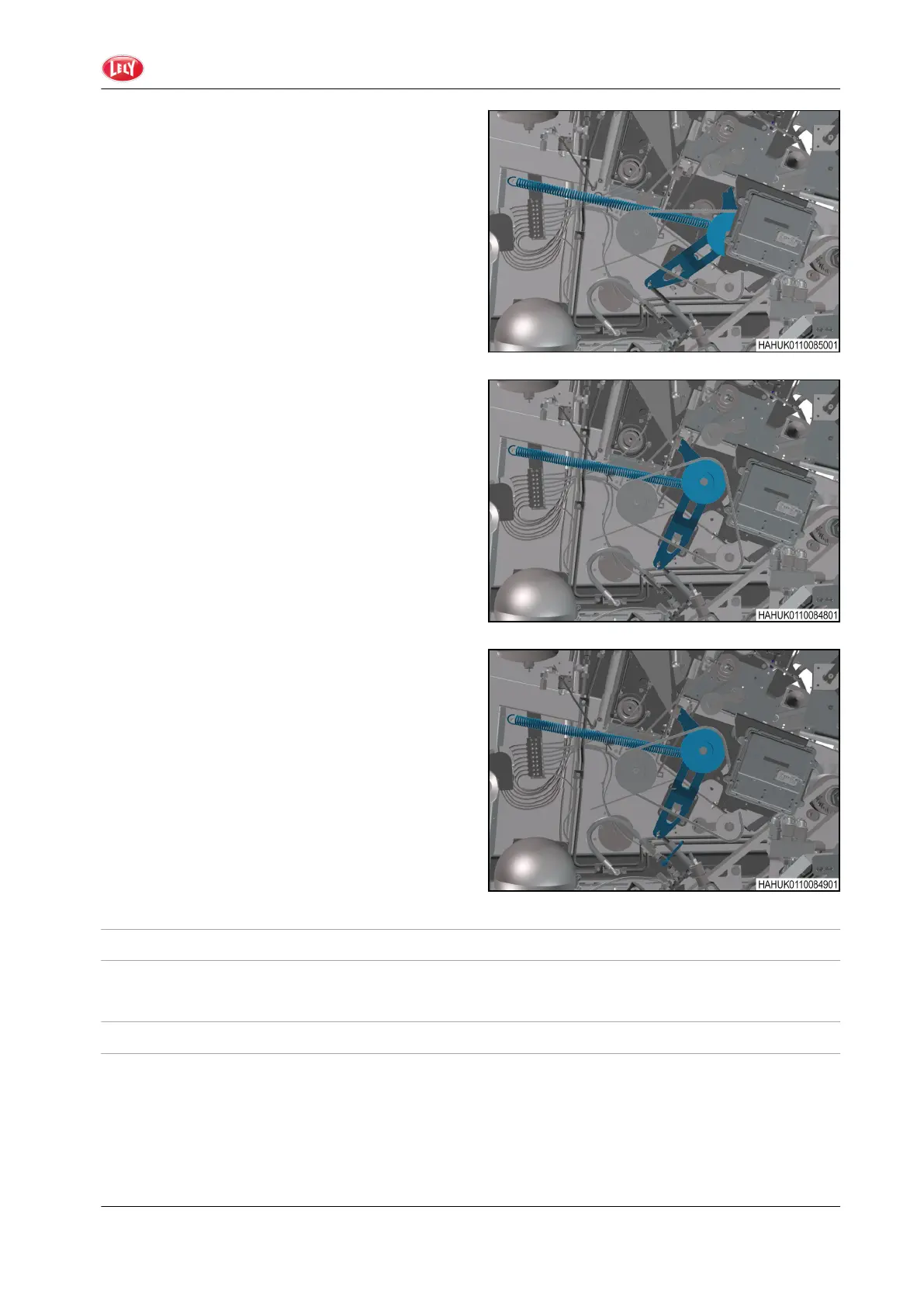

The pivoted roller will move to the front of the

machine when the hydraulic line, to open the

tailgate, has pressure. During baling the pivoted

roller will be in the front position.

GUID-09A3BAC1-8B5D-419D-9A9F-B48EAB963FE4-high.jpg [High]

Fig. 5

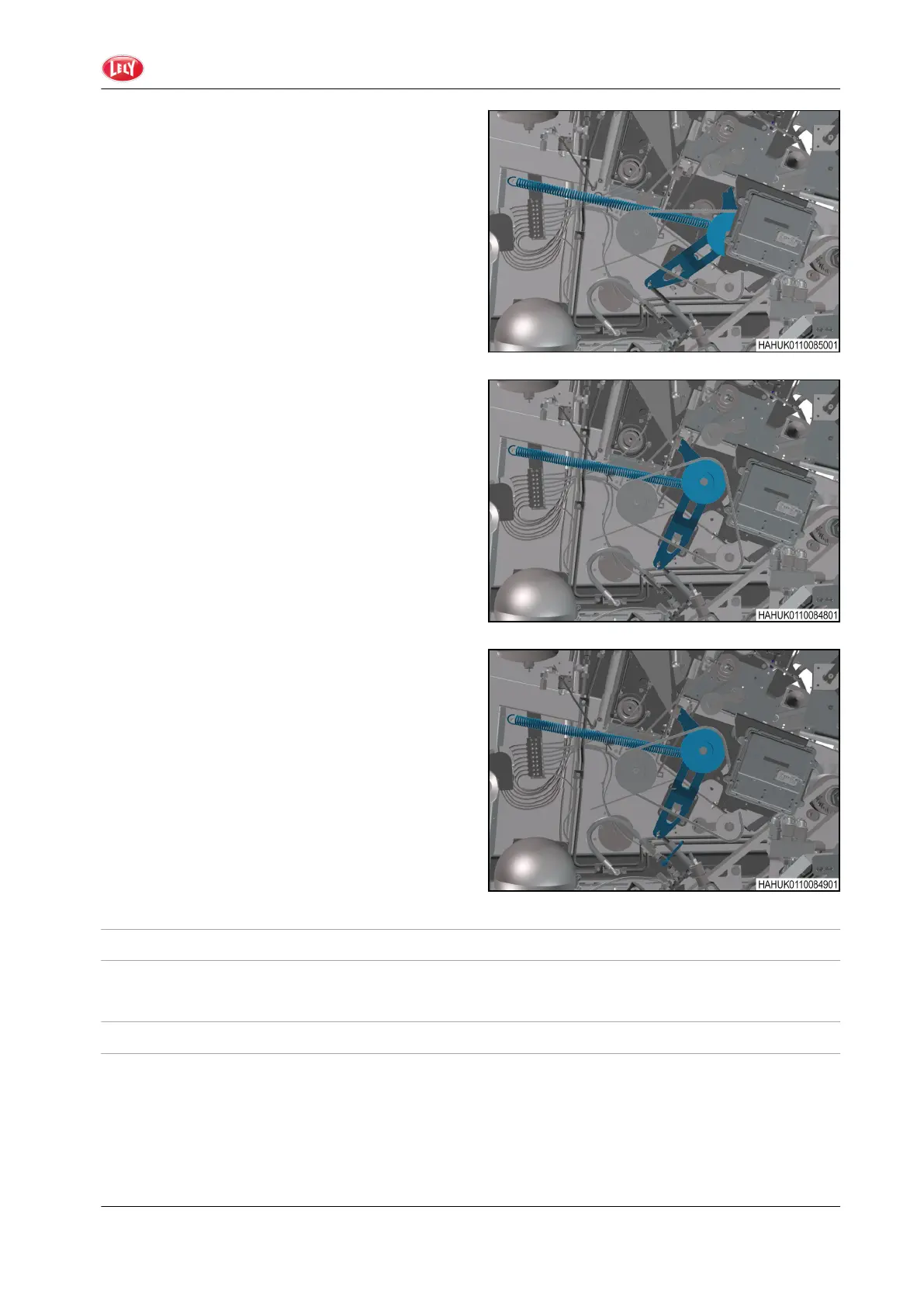

The pivoted roller will move to the rear position for

tying the bale with net. The valve will operate the

change of position. When the valve operates, the

spring pulls the roller to the rear of the machine.

The valve operates by electronics. It is possible to

manually operate the valve.

GUID-EC7CF457-C904-46A8-8DAF-EBC1B6B46B03-high.jpg [High]

Fig. 6

In machines with dual tying (net and twine) the

roller is in the rear position. With the ball valve not

open, as shown the roller will not move to the

position at the front of the machine.

GUID-502E6ED2-F360-458B-9D33-3043D960F758-high.jpg [High]

Fig. 7

2.3.14 Bale Transfer

When the tailgate opens the bale rolls out on to the bale transfer. The bale transfer can tilt hydraulically.

From the tilted bale transfer the bale rolls on to the wrapping table.

2.3.15 Wrapper

The primary parts of the wrapper are the:

• Wrapping table

• Wrapping ring

• Stretch unit

• Film knife.

GUID-EB82025E-38DE-478C-AB0E-A75E7CDBA75E [V1]

GUID-B0617EF3-6EFD-4DFD-A378-685D772D4F31 [V1]

2. Introduction

Baler Wrapper Combination 43

4900.LE.EN01

Loading...

Loading...