MM-400A

8. Operation Screens

8-72

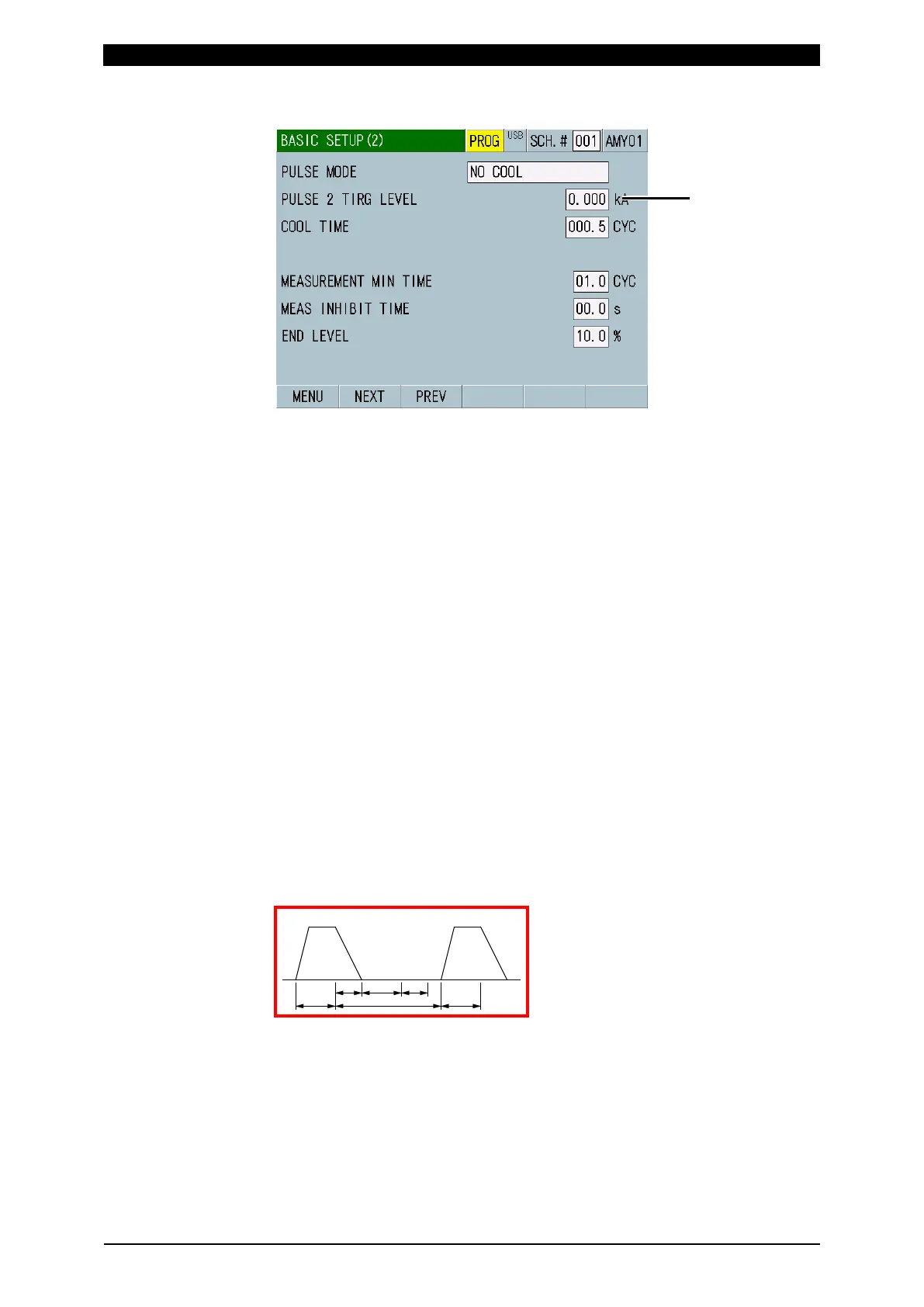

When PULSE MODE is NO COOL

(1) SCH.#

Shows the measurement schedule number used (1 to 127). On the other hand,

you can change schedules by selecting this field and inputting a value.

(2) Schedule name

Shows the name of SCH.#. This can be set in the BASIC SETUP (1) screen.

(3) PULSE MODE

For a standard single pulse spot welding, select SET PULSE for PULSE

MODE, and “00” for PULSE No.

Current may be passed several times in a single welding sequence. Use the

impulse settings to measure an arbitrary step, all steps, and the second step in

the 2-step welding with no cooling time. Waveforms of all numbers of

measured times are displayed.

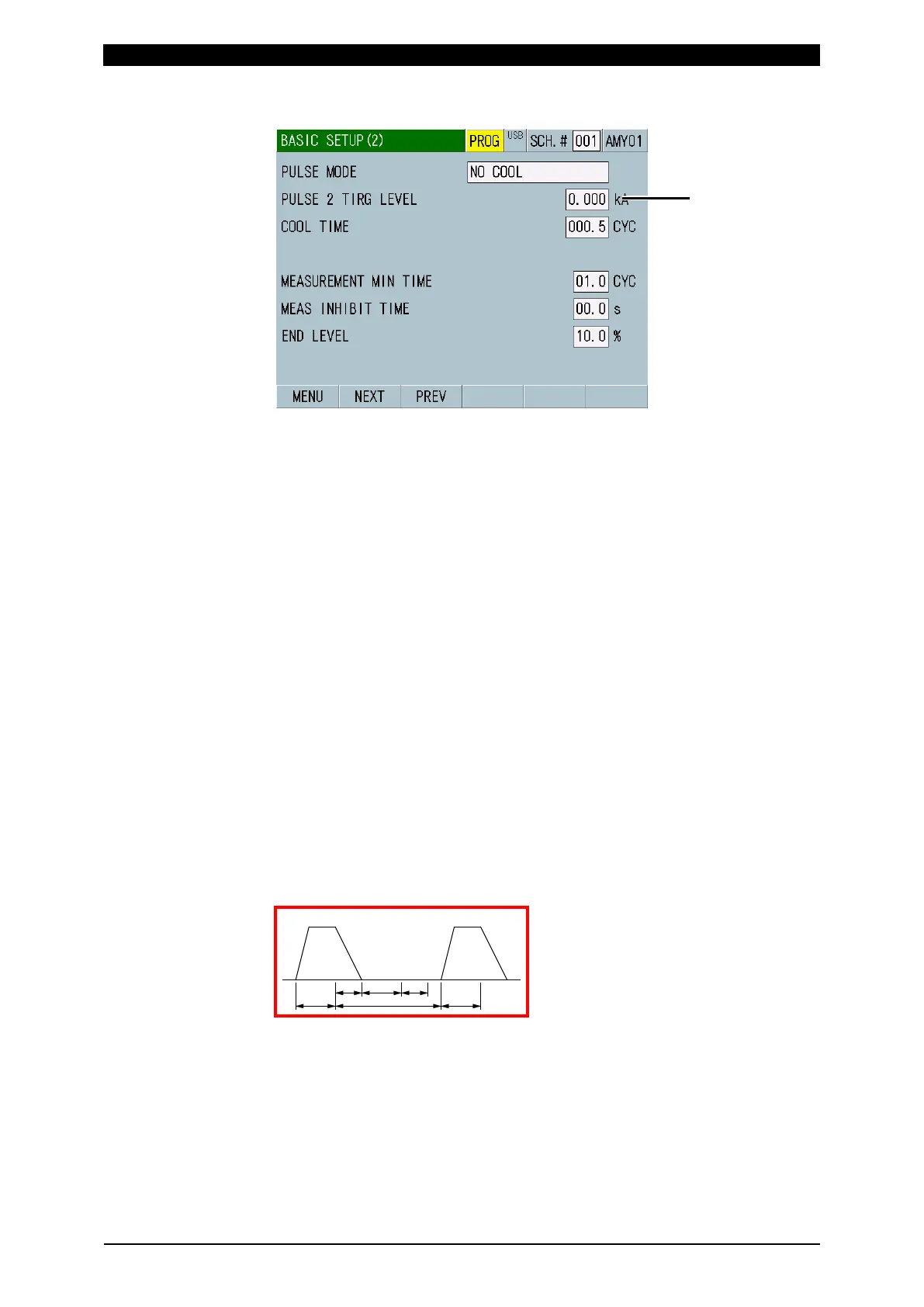

(Note) Current flow interval

The cooling time of the welding power supply should be longer than the

following current flow interval (time that current does not flow). If the time is

shorter, the impulse measurement cannot be performed. The current flow

interval should be longer than c + d + e shown below.

For COOL TIME of MM-400A, set the time shorter than that of the welding

power supply. (Use the initial setting of 0.5 CYC or 1 ms.)

Also, when COOL TIME of MM-400A is longer than that of the welding power

supply, the measurement is performed as the same pulse.

a: WELD (weld time of the welding power supply)

b: COOL (downtime of the welding power supply)

c: Time until current falls below the END LEVEL setting

d: Time set in COOL TIME

e: 1 CYC when TIME is CYC, 2 ms when TIME is ms

For TIME, refer to Chapter 8, “l-1. BASIC SETUP (1) Screen.”

Even if the impulse settings are used, a welding longer than the following

measurable time cannot be measured. The cooling time is included.

Loading...

Loading...