MM-400A

6. Installation and Connections

6-3

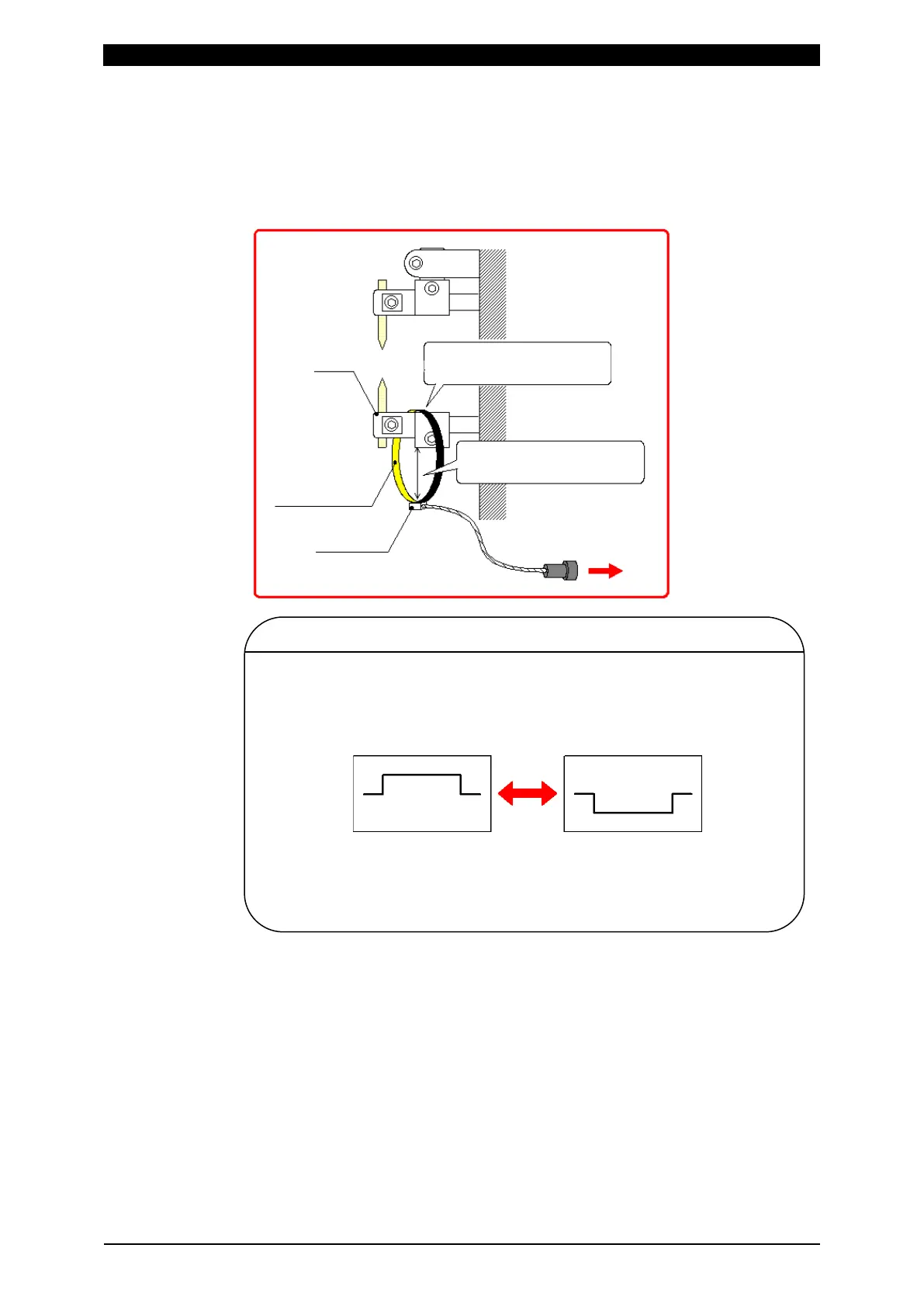

2) Fit the toroidal coil onto the welding machine’s arm or secondary conductor.

When fitting the coil, be careful with the following:

• Keep the toroidal coil’s hooking bracket as far away from the welding

machine’s arm (secondary conductor) as possible.

• Do not deform the circular form of the toroidal coil when fitting it.

CAUTION

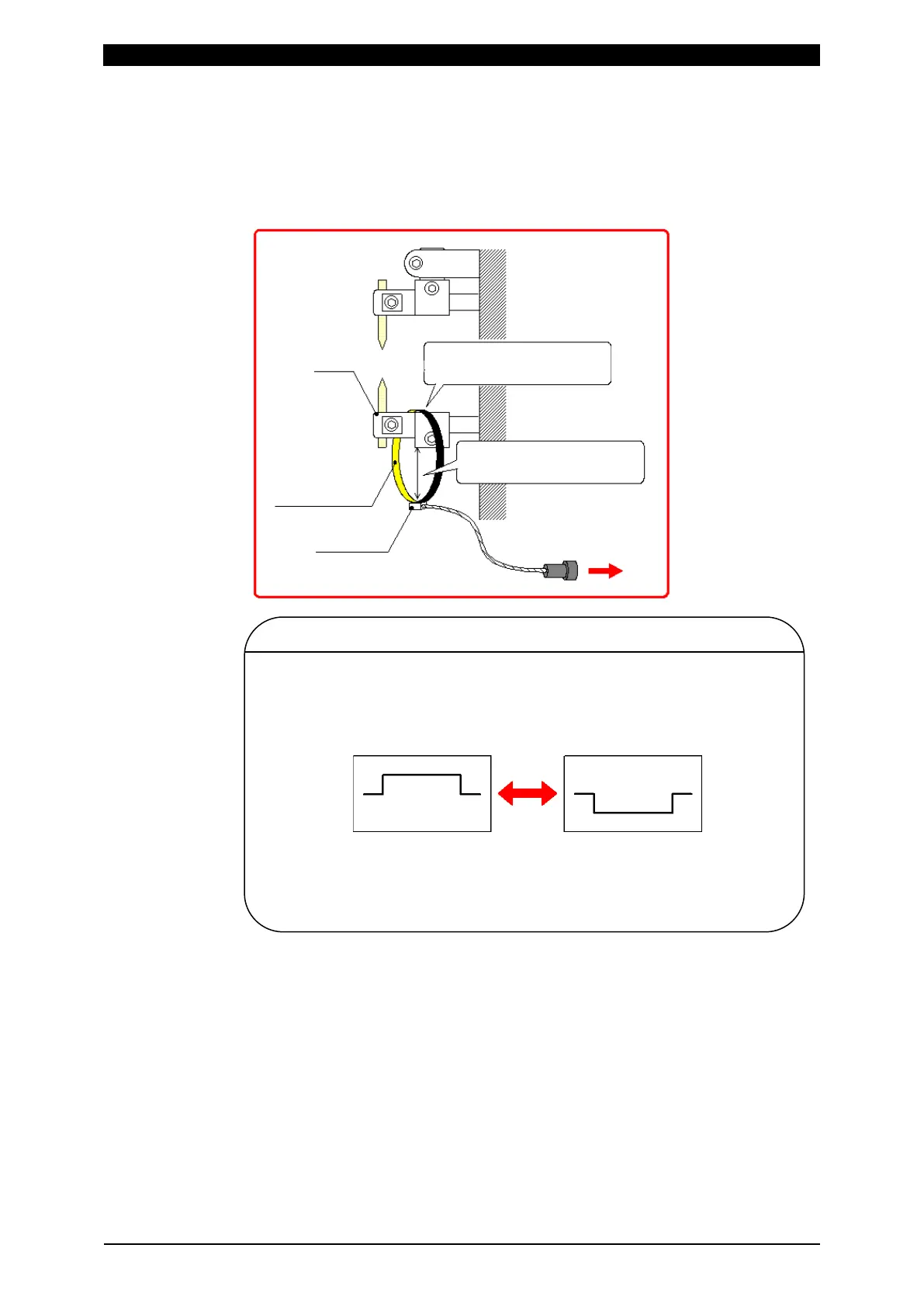

• If the toroidal coil is fitted in reverse orientation, the waveforms in the

WAVEFORM screen and the analog output waveforms measured with

the oscilloscope are also shown in reverse. The analog output (current

and voltage) is output in reverse side of the waveforms in the

WAVEFORM screen.

• For a band-type toroidal coil, do not deform it when fitting it. Repeated

bending and extension may break internal wires.

• The ISO toroidal coil (MB-400M/800M) has an arrow. For DC

measurement, match the direction of an arrow and a current.

Do not deform the circular

form of the toroidal coil.

Keep the hooking bracket at the

furthest point from the arm.

Loading...

Loading...