Chapter 5 ROUTINE MAINTENANCE

5 - 2

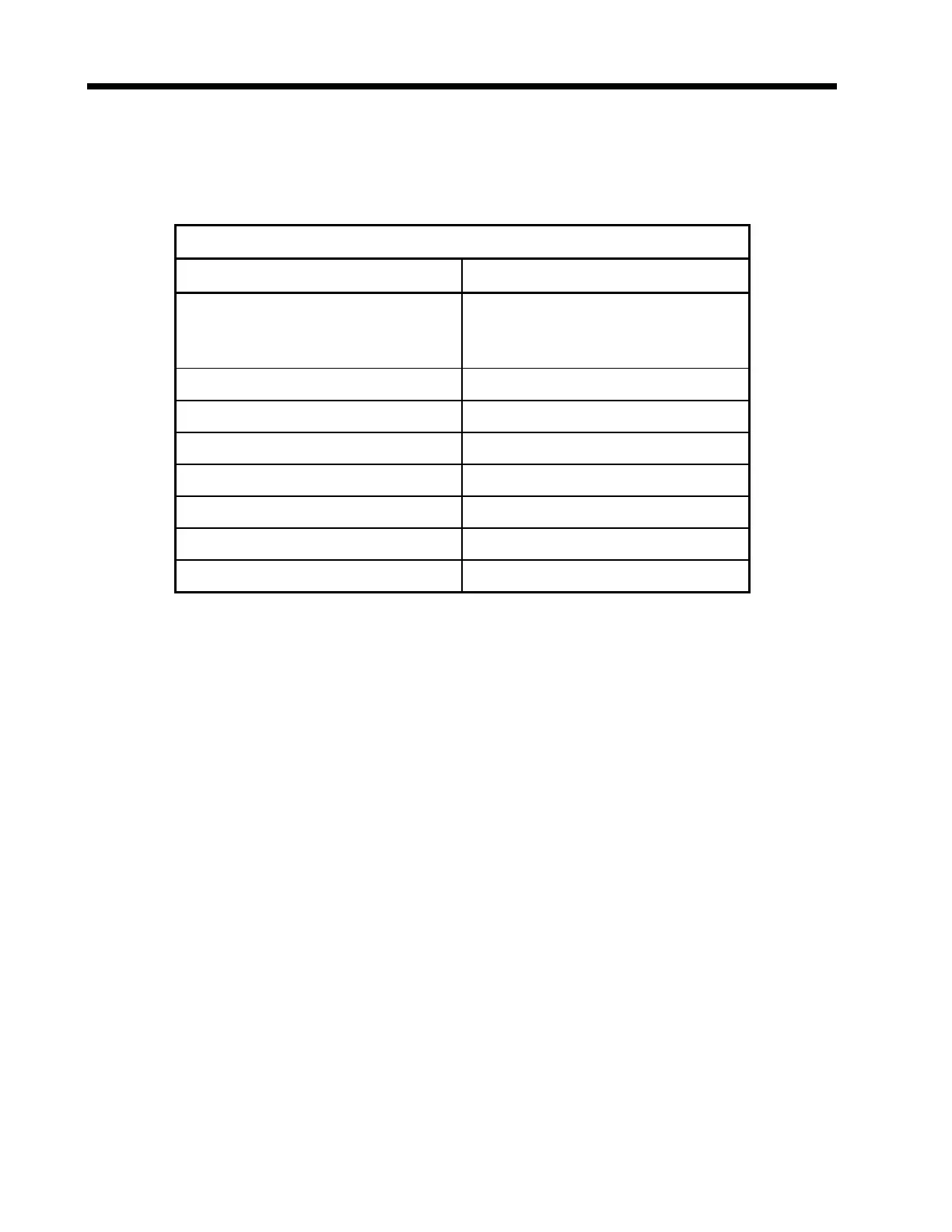

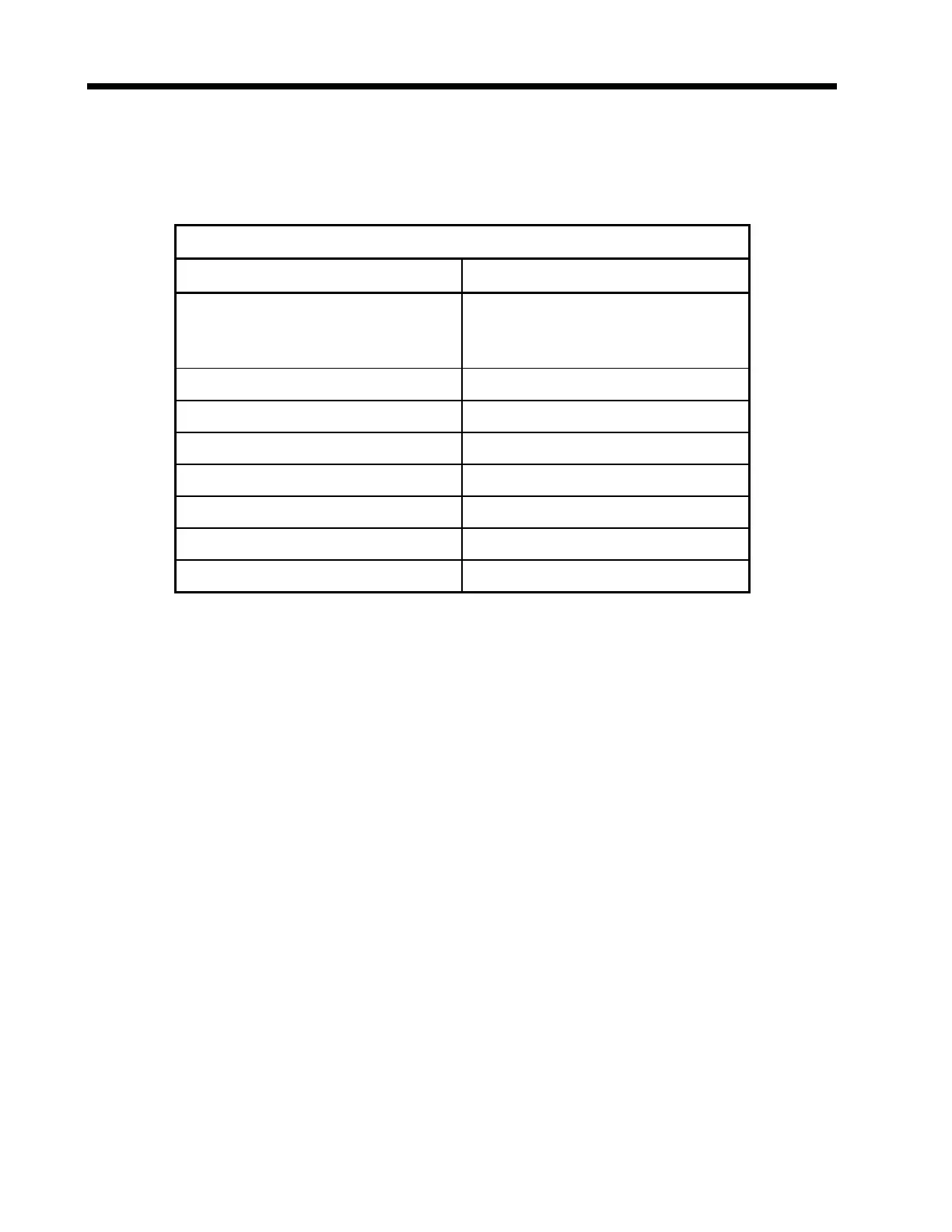

The exterior surfaces of the pump may be cleaned with any of the agents listed in Table

5-1 when used in accordance with manufacturer’s instructions. Some caustic cleaning

agents are known to degrade the integrity of the case material. Only those cleaners listed

in Table 5-1 used appropriately have been tested with positive results.

TABLE 5-1

Cleaner Manufacturer

5%-10% solution of chlorine

bleach and water (1:19 to 1:9

ratio)

Commercially available

Cidex and activator Arbrook

Manu-Klenz® Steris Corp.

LPH SE Steris Corp.

Vesphene® II SE Steris Corp.

Hi-Tor® ECO Labs

Tor® ECO Labs

Bafix Hysan/AM

NOTE

Do not use cleaning solutions containing n-alkyl dimethyl ethylbenzyl

ammonium chloride. This compound is known to degrade plastic

components over time.

5.2.1.4 General Guidelines

• The charger plug and power switch areas must be kept clean and dry at all

times. Do not clean the pump while the charger is plugged in.

• Some liquids spilled into the barrel clamp area may temporarily cause

excessive CHECK SYRINGE, CHECK FLANGE OR CHECK BARREL

messages. Proper operation is generally restored after the barrel clamp dries.

• If routine cleaning does not restore proper operation, the pump should be

removed from service and given a “service cleaning”. This procedure is

described in Section 5.2.2.

• The pump may not be sterilized by autoclave, ETO, gamma ray, or any other

method that is harmful to plastic materials or electronic devices.

• Do not use spray solvents or any type of penetrating oil.

5.2.2 Service Cleaning

Loading...

Loading...