S83/85 Ultrasonic Generator Troubleshooting

A40-064 Rev 0 Page 79

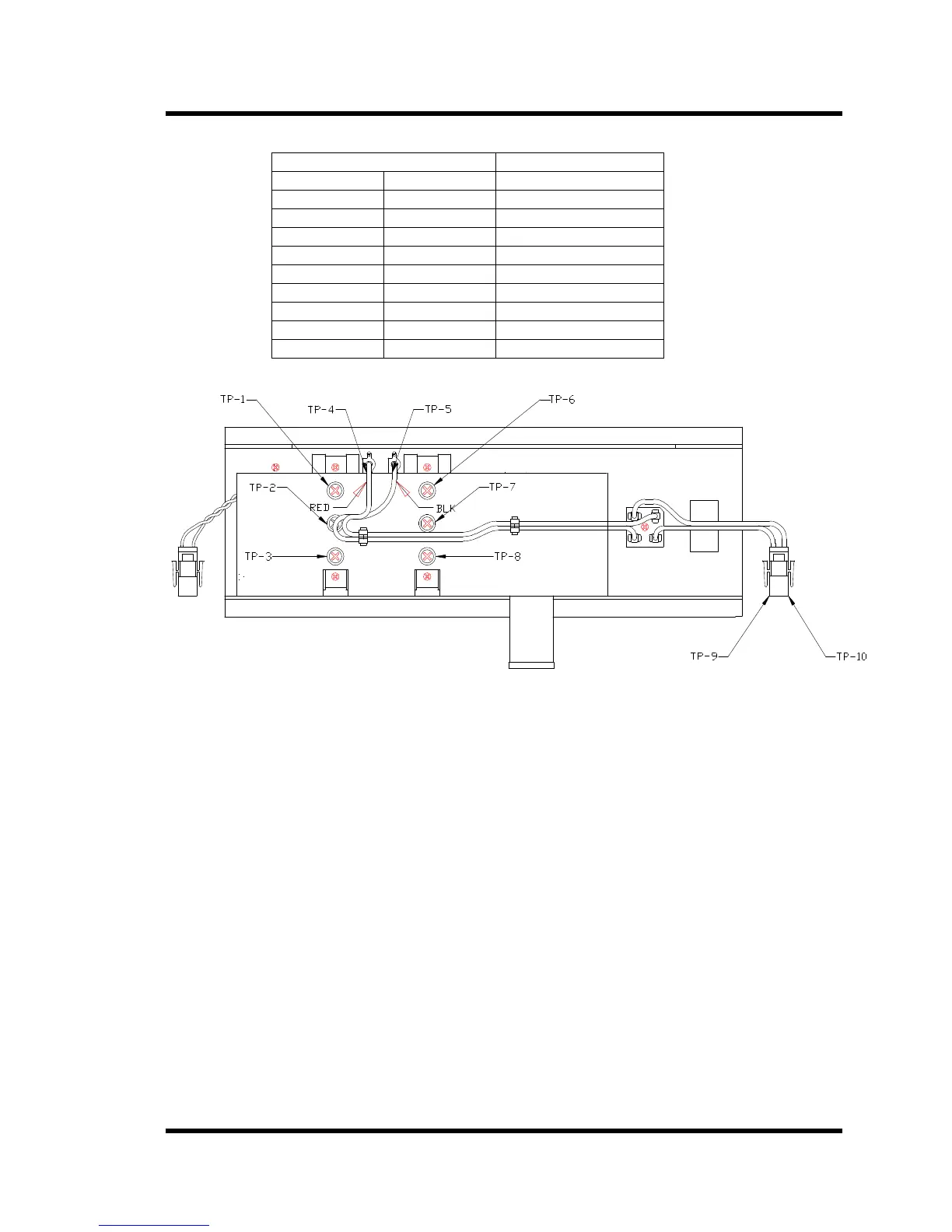

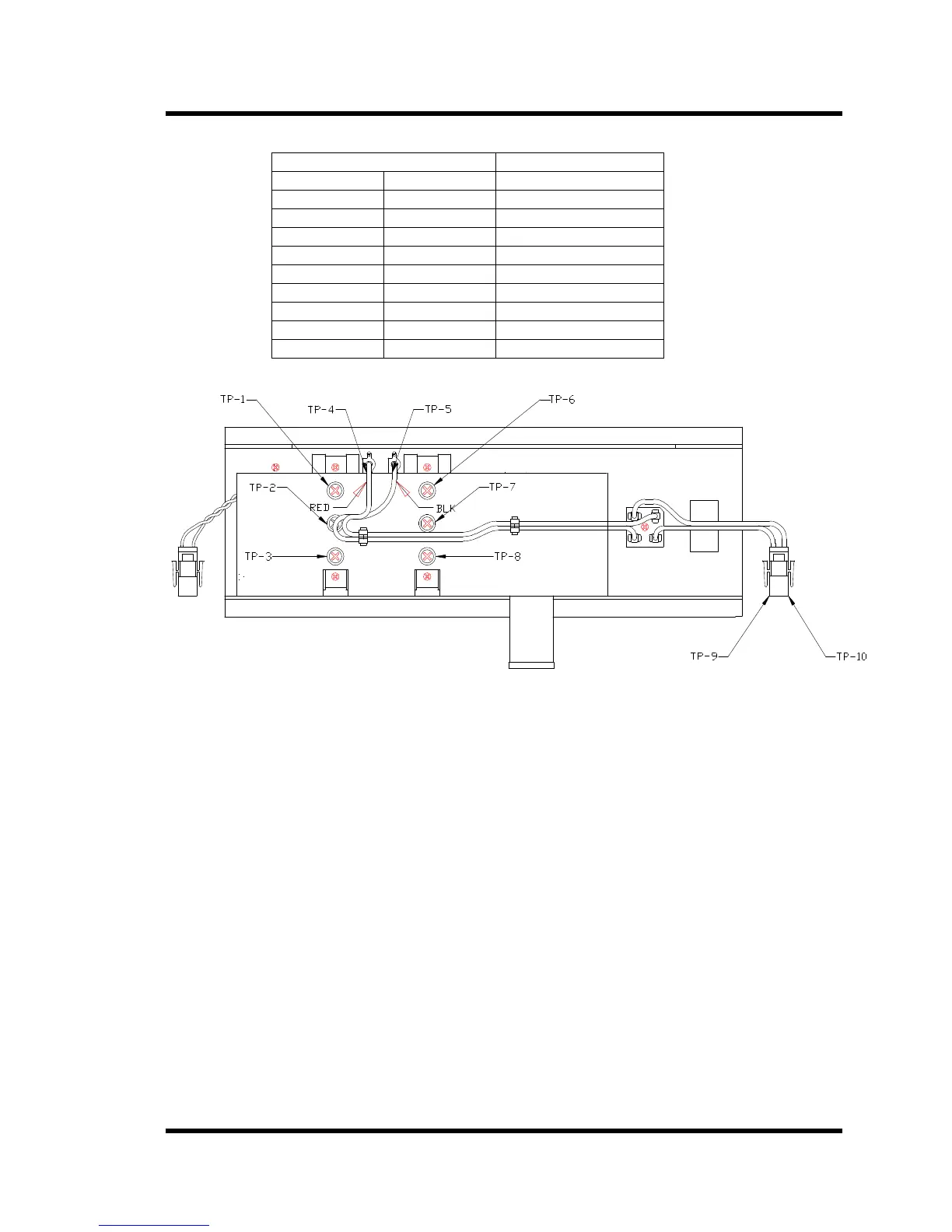

Table 10 Diode Resistances

Diode meter test leads Reading

+ -

TP-1 TP-2 OPEN-CIRCUIT

TP-2 TP-3 0.35-0.55

TP-3 TP-1 0.35-0.55

TP-6 TP-7 OPEN-CIRCUIT

TP-7 TP-8 0.35-0.55

TP-8 TP-6 0.35-0.55

TP-5 TP-4 0.7-1.0

TP-9 TP-10 OPEN-CIRCUIT

TP-10 TP-9 OPEN-CIRCUIT

Figure 6-1 Driver Board Test Points

6.5 Cavitation Erosion

Cavitation erosion is a natural consequence of operating ultrasonics. It appears initially as a

dulling of the radiating surface and proceeds to pitting and eventually may penetrate the metal so

that the tank or transducer becomes unusable. The rate of erosion depends upon the ultrasonic

frequency, the temperature of the liquid, the chemistry in the tank, the hardness of the tank, the

power setting of the generator and many other factors.

6.5.1 Repairing Cavitation Erosion Marks

There is no reliable method of repairing cavitation erosion

6.5.2 Minimizing Cavitation Erosion

To reduce cavitation erosion:

• Operate the ultrasonics only when actually cleaning parts.

• Set the power level to the minimum setting that will produce clean parts.

Loading...

Loading...