S83/85 Ultrasonic Generator Options

A40-064 Rev 0 Page 93

Attach and lock the I/O board’s ribbon cable to the power supply’s main board header J7.

Attach and lock the I/O board’s two wire harnesses to the power supply’s main board

header J20.

Place the top cover back on the power supply and secure to the sides with screws.

7.3.4 OEM I/O Operation

The OEM I/O is functionally in parallel with the front panel US switch. Two external

functions are provided with the I/O board, ultrasonics ON/OFF and ultrasonics ON/OFF

status. Both functions are accessed through a 4 position terminal block located on the

end of the I/O board. Ultrasonics can be toggled on or off from a dry switch closure or a

24VAC or 24VDC source, depending on how the I/O board is configured. The factory

setting is for dry switch closure. Ultrasonic ON/OFF status is read from a normally open

output relay contact on terminals 3 and 4 of the terminal block.. Ultrasonic ON/OFF

control is activated from terminals 1 and 2 of the terminal block.

7.3.5 Specifications

Isolation Type Voltage Range Maximum Current

Input: Optical 12-30 VDC

10-27 VAC

N/A

Output: Relay 0-30 VDC

0-48 VAC

N/A

The OEM I/O board can be configured to activate ultrasonics with an external switch

closure or an external 24 VAC oe 24 VDC voltage source.

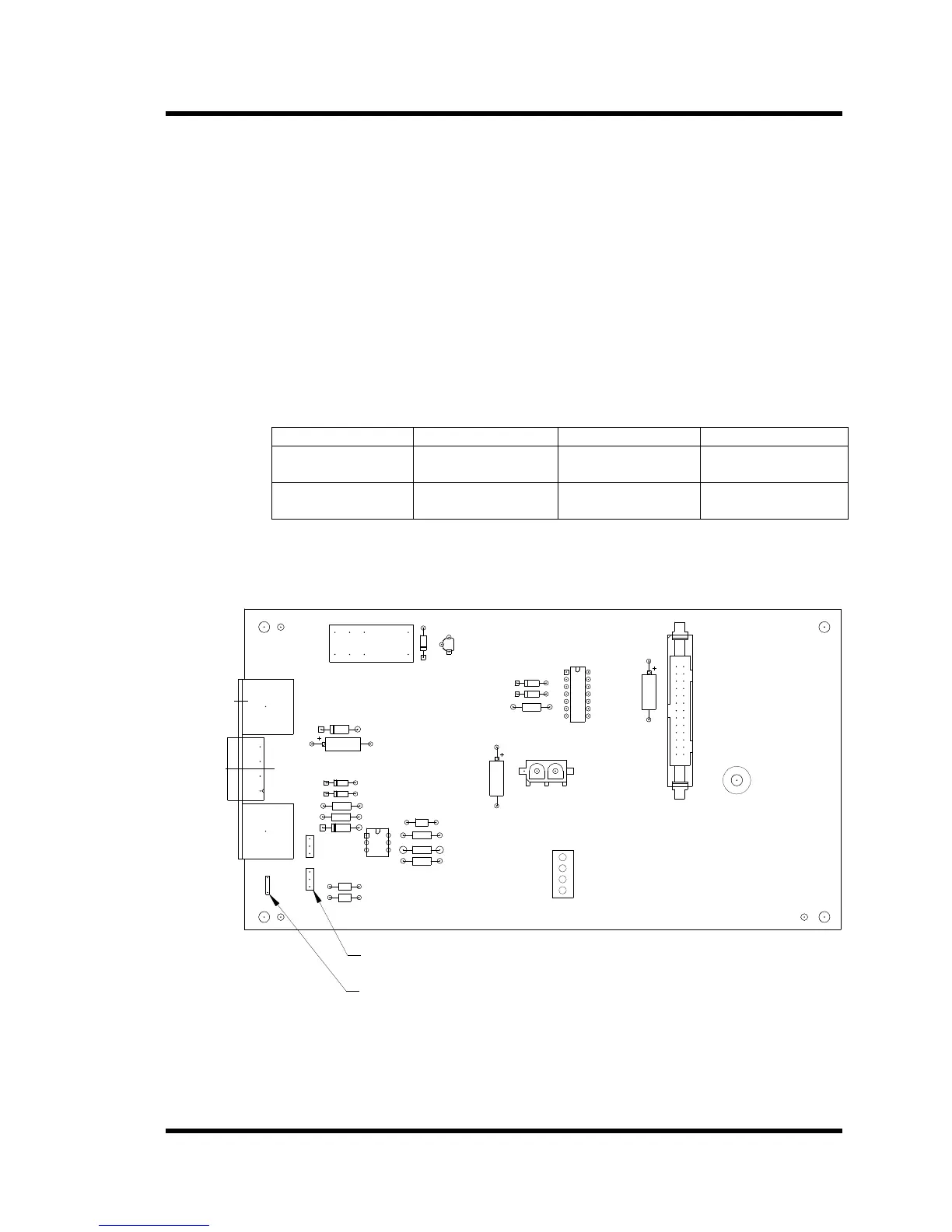

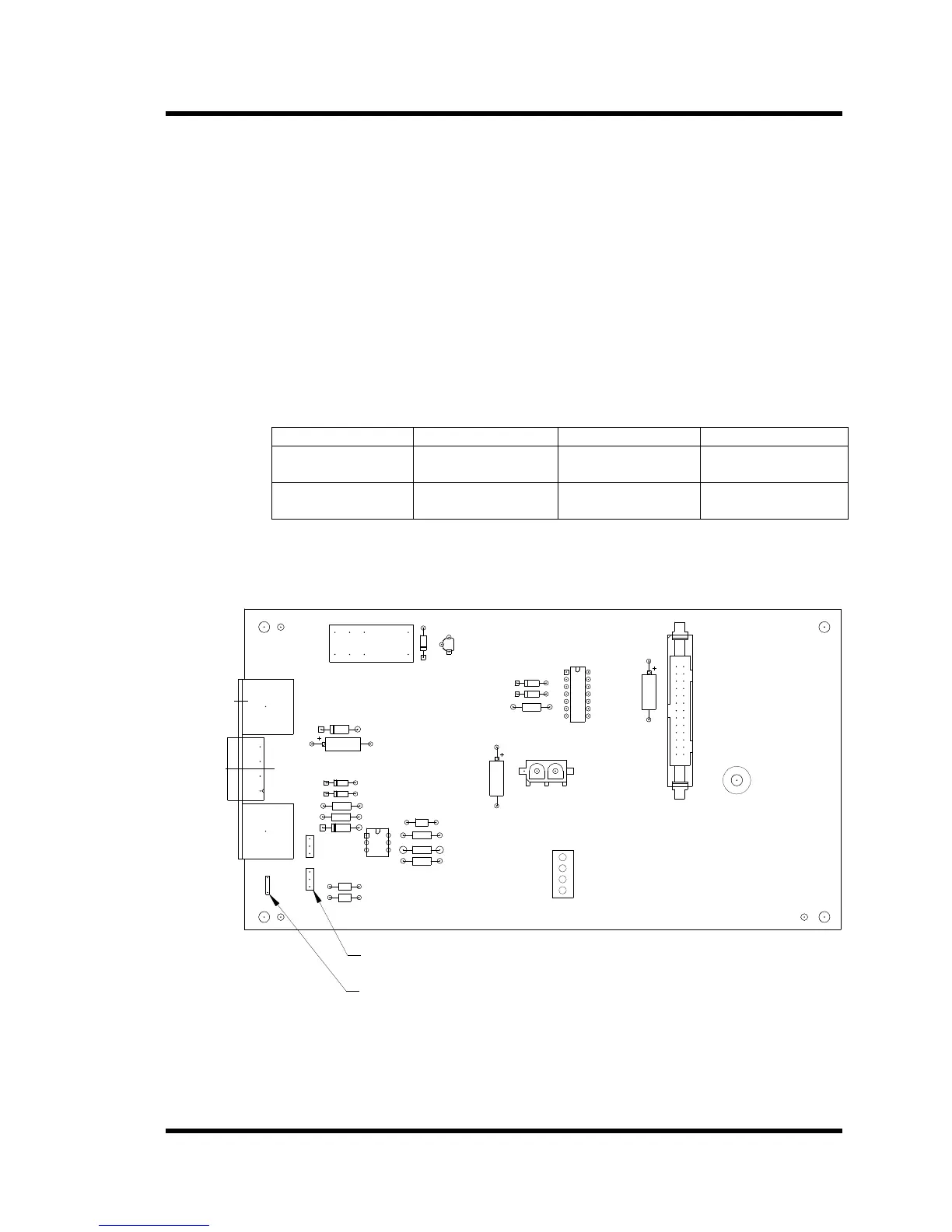

Figure 7-10 OEM I/O Configuration

1 2 31 2 3

JP2 ON PINS 2 AND 3

SET: JP1 ON PINS 2 AND 3

2) FOR 24VAC OR 24VDC ACTIVATION

JP2 ON PINS 1 AND 2

SET: JP1 ON PINS 1 AND 2

TERMINAL 4

TERMINAL 3

TERMINAL 2

TERMINAL 1

CONNECTIONS J2

TERMINAL BLOCK

TERMINALS 4 AND 3: RELAY OUTPUT

TERMINALS 2 AND 1: U/S ACTIVATION

1) FOR DRY SWITCH ACTIVATION

U/S ACTIVATION PROGRAMMING MODES

100-242-324R REV 3

BRANSON ULTRASONICS CORP.

OEM I/O PC BD

JUMPERS

GROUND WIRE CONNECTION

JP1 JP2

Loading...

Loading...