2007 Buell Lightning: Chassis 2-51

HOME

12. Move the front fork and the FORK TUBE HOLDER TOOL

in the vise from the horizontal position to the vertical.

NOTE

The recommended fork oil is hydraulic fork oil Type “E” (Part

No. HD-99884-80).

13. Pour 8 oz. (236.5 cc) into the fork pipe.

14. Pump the damper rod approximately 12 to 15 times or

until resistance is felt.

15. Place the damper rod in the fully bottomed position and

compress fork completely.

16. Pour 8 oz. (236.5 cc) more fork oil into the slider fork.

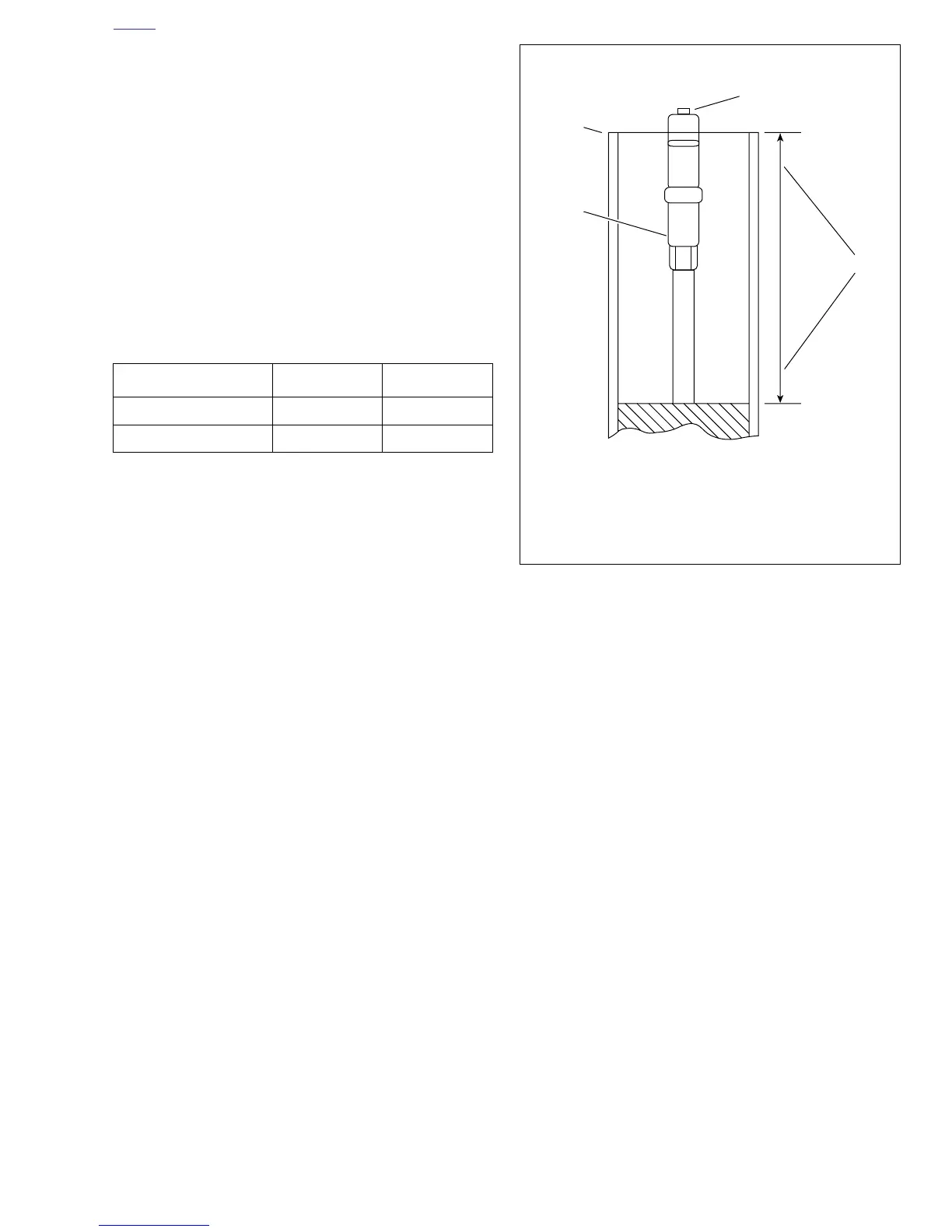

17. See Figure 2-73. Adjust fork oil level with FRONT FORK

OIL LEVEL GAUGE (Part No. B-59000A) to the specified

level below the top of the fork tube. Refer to Table 2-14.

18. See Figure 2-69. Install spring (17) and collar (15).

19. Move fork assembly from holding tool to the FORK

SPRING COMPRESSION TOOL.

20. See Figure 2-68. Install preload washer (4) and slider

piston (5).

21. See Figure 2-71. Hold damper rod assembly (3) and

install fork cap (1) on damper rod assembly (3) tightening

to 38-42 ft-lbs (51-57 Nm).

NOTE

See Figure 2-68. Careful not to damage preload pins (2)

while holding damper rod assembly (3).

22. Remove the fork assembly from the FORK SPRING

COMPRESSION TOOL and install in the FORK TUBE

HOLDER and install in vise.

23. See Figure 2-69. Thread fork cap (3) into fork tube (18)

and tighten to 22-30 ft-lbs (29.8-40.6 Nm).

24. Apply fork oil or light grease to o-rings on preload

adjuster and install preload adjuster (3).

25. Install snap ring (2).

Table 2-14. Fork Oil Levels

Model Inch MM

XB9SX, XB12S, XBSs 4.21 107

XB12Scg 4.29 109

Figure 2-73. Measuring Fork Oil Level

b0666x2x

3

2

1. Outer tube

2. Adjuster

3. Damper assembly

4. Fork oil level

1

4

Loading...

Loading...