3-30 2007 Buell Lightning: Engine

HOME

Installing Engine in Frame

NOTE

Vehicle should be placed onto the lift with rear tire in the

wheel vise in order to successfully perform this procedure.

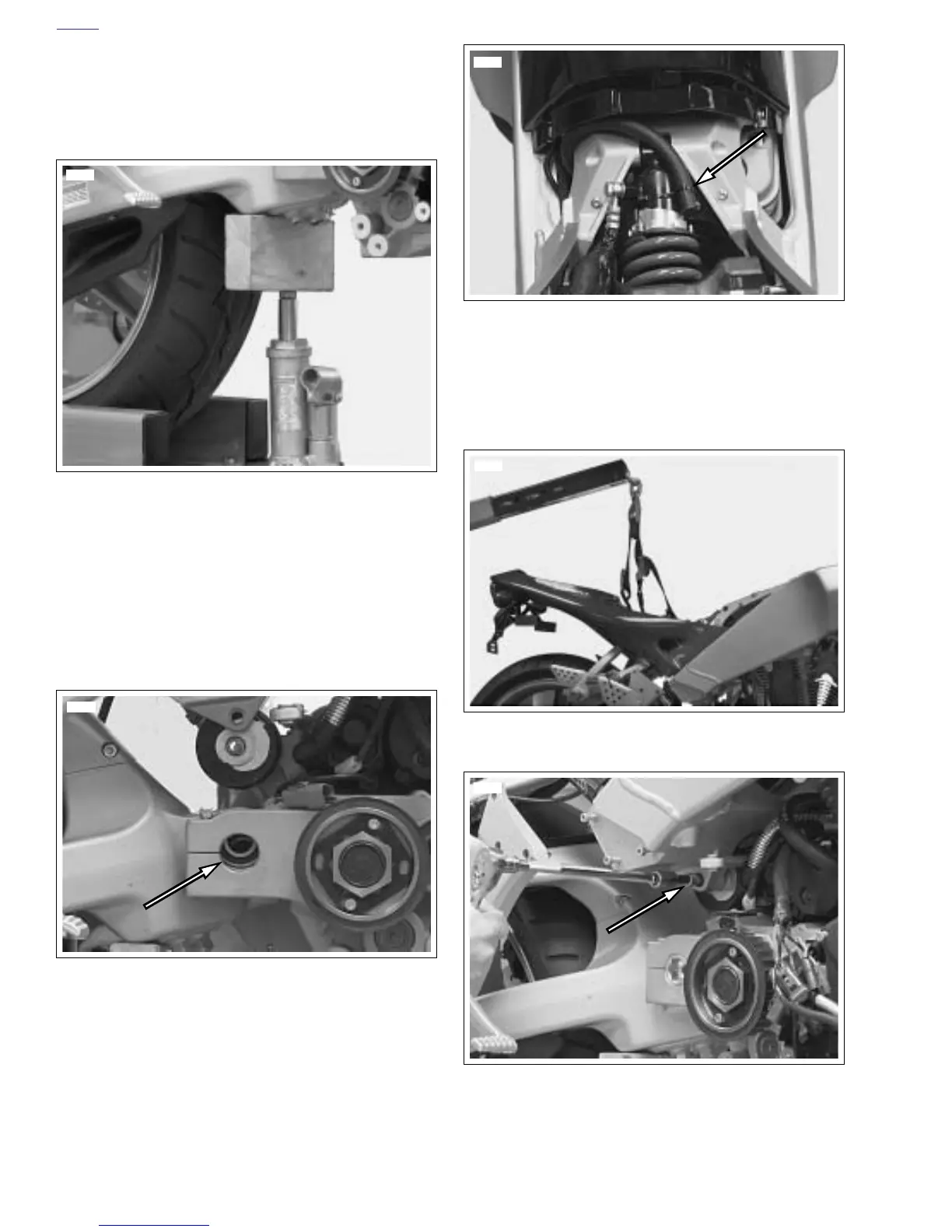

1. See Figure 3-37. Install bottle jack and wooden block

under swingarm/oil tank to the rear of the oil line fittings.

NOTE

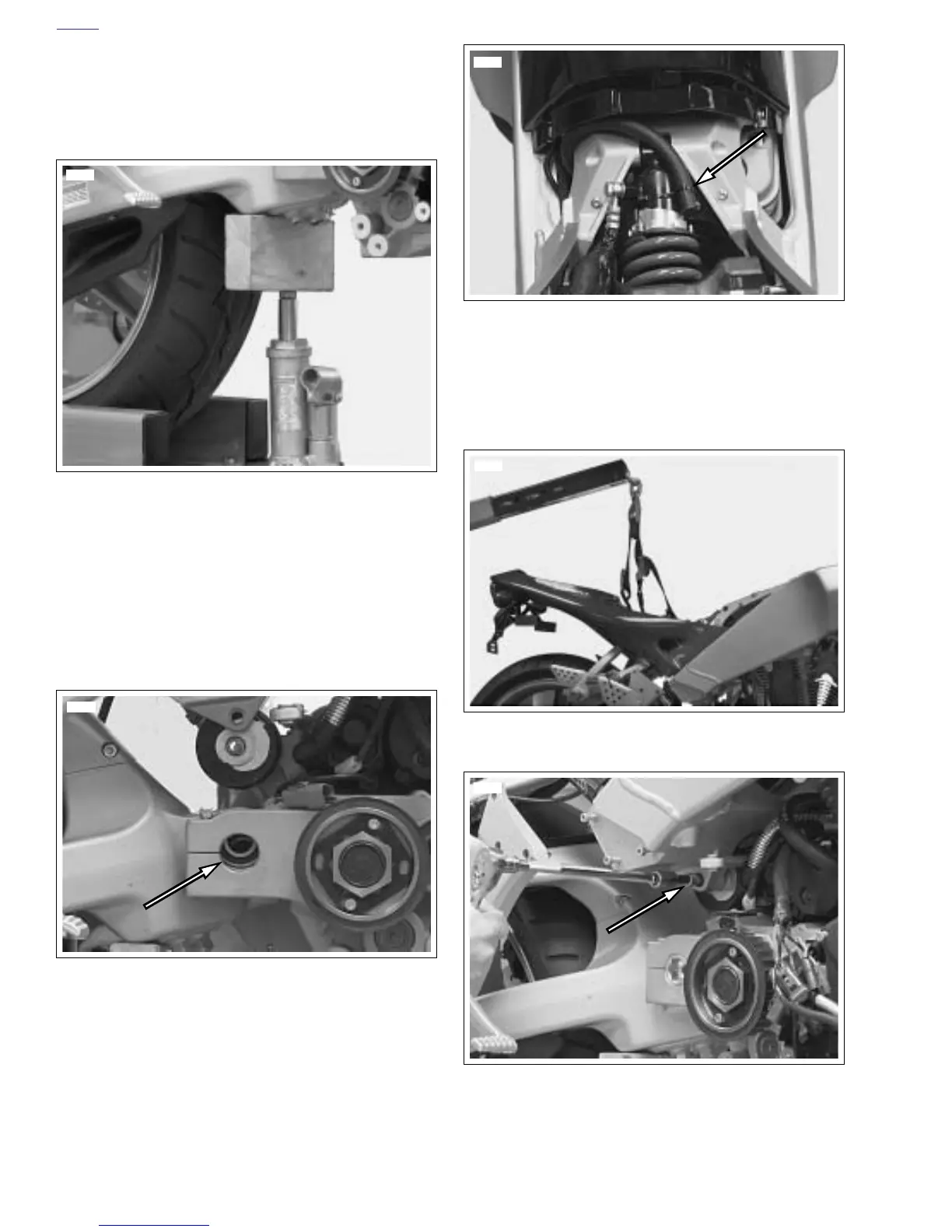

See Figure 3-40. At this point it is necessary to support main

frame with overhead hoist in order to install rear isolator bolt.

2. Remove ratcheting tie down and block of wood between

rear isolator mount on main frame and swingarm/oil res-

ervoir.

3. See Figure 3-38. With engine on a flat scissors jack,

raise engine and chassis until swingarm and rear isolator

mount align and pivot shaft can be installed.

4. Apply anti-seize to swingarm pivot shaft threads and

tighten swingarm pivot shaf to 24-26 ft-lbs

(32.5-35.2 Nm).

5. Apply LOCTITE 271 (red) and tighten swingarm pivot

shaft pinch bolt to 17-19 ft-lbs (23-25.8 Nm).

6. See Figure 3-39. Route transmission vent line up

through left side of frame exiting under the left rear side

of the intake cover assembly. Install cable strap to secure

transmission vent line in place. Inspect vent line to verify

space between vent line and rear exhaust.

7. See Figure 3-41. Using the overhead hoist to align the

frame to the rear isolator, install rear isolator bolt and

leave loose at this time.

Figure 3-37. Supporting the Swingarm (Typical)

Figure 3-38. Aligning Swingarm to Crankcase for Pivot

Shaft Installation (Typical)

8719

8771

Figure 3-39. Transmission Vent Line

Figure 3-40. Supporting Vehicle for Assembly (Typical)

Figure 3-41. Installing Rear Isolator Bolt (Typical)

8918

8716

8722

Loading...

Loading...