4-12

ADJUSTMENT

Idle

See IGNITION TIMING in Section 1.

Enrichener Control

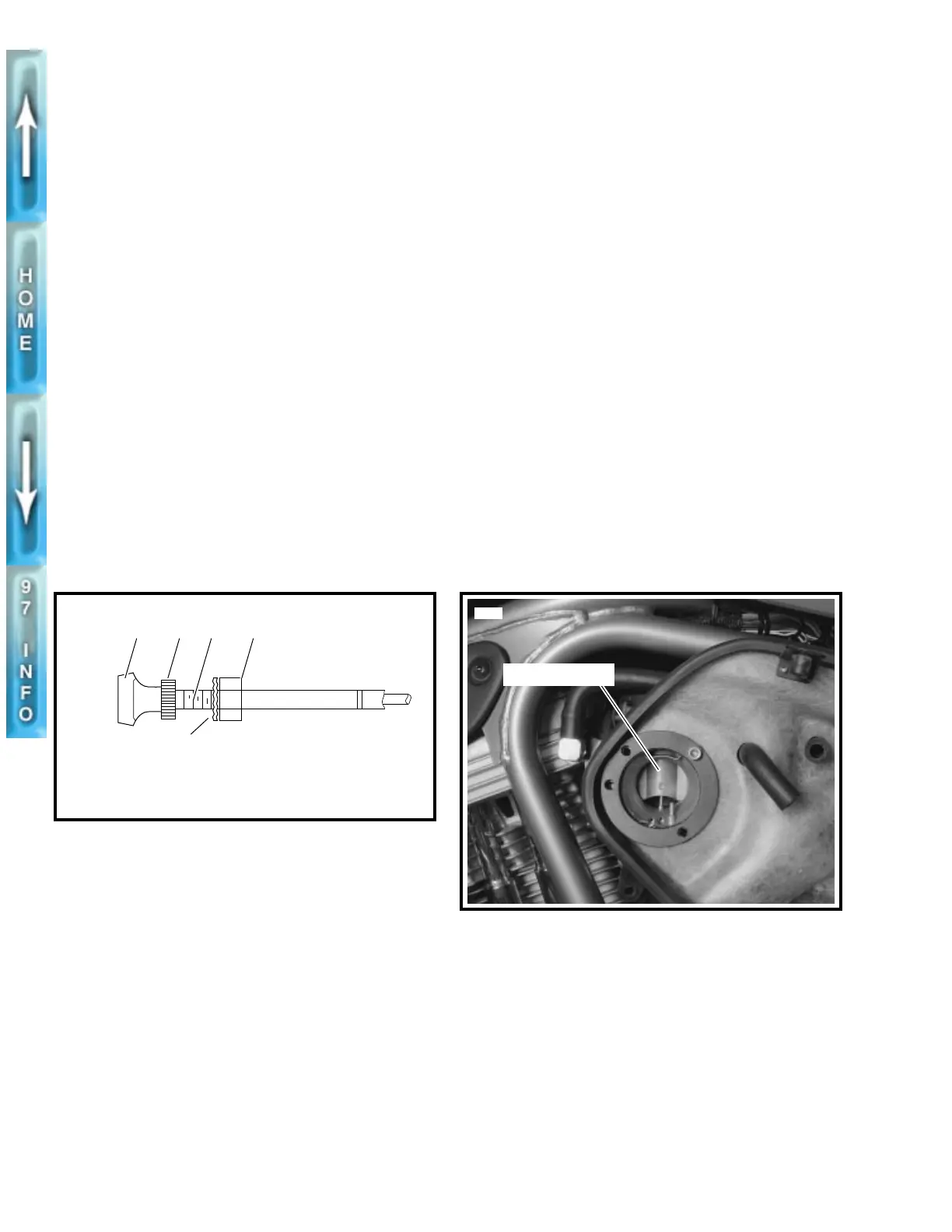

See Figure 4-9. Check enrichener operation. Enrichener knob

(1) should open (and remain open) and close without binding.

Plastic nut (2), next to the enrichener knob, controls the sliding

resistance of the enrichener control cable within the cable con-

duit. If adjustment is needed, perform the following:

1. Loosen hex nut (5) at backside of mounting bracket.

2. Move cable assembly free of slot in mounting bracket.

3. Hold cable assembly at flats (4) with a wrench. Adjust

resistance until knob slides outward and remains fully

open without assistance. Knob must also slide inward

unaided.

a. Turn plastic nut (2) by hand counterclockwise

(reducing sliding resistance).

b. Turn plastic nut clockwise (increasing sliding resis-

tance).

4. Position cable assembly into slot in mounting bracket.

Tighten hex nut at backside of bracket.

NOTE

Do not lubricate the cable or inside of conduit. The cable must

have friction to work properly.

Float Level

1. Remove carburetor and place on a flat, clean surface on

engine manifold side. This is the “base.” Tilt carburetor

counterclockwise 15˚ to 20˚ from base until float comes

to rest. See Figure 4-11.

NOTE

If carburetor is tilted less than 15˚ or more than 20˚, your

measurements will be inaccurate.

2. Use a vernier or dial caliper depth gauge to measure

from the carburetor flange face to the perimeter of the

float. Be careful not to push on float while measuring.

The measurement must be 0.413-0.453 in.

(10.49-11.51 mm). If measurement is not within given

dimension, remove float and carefully bend tab in order

to reposition float at proper level.

3. Install float and recheck setting.

4. Install float bowl. Install carburetor as described in CAR-

BURETOR, INSTALLATION on page 4-17.

OPERATION CHECK –

VACUUM PISTON

Opening Malfunction

1

WARNING

While observing piston slide movement, be sure to main-

tain a safe distance from the carburetor and to wear suit-

able eye protection. An unexpected engine backfire could

cause personal injury.

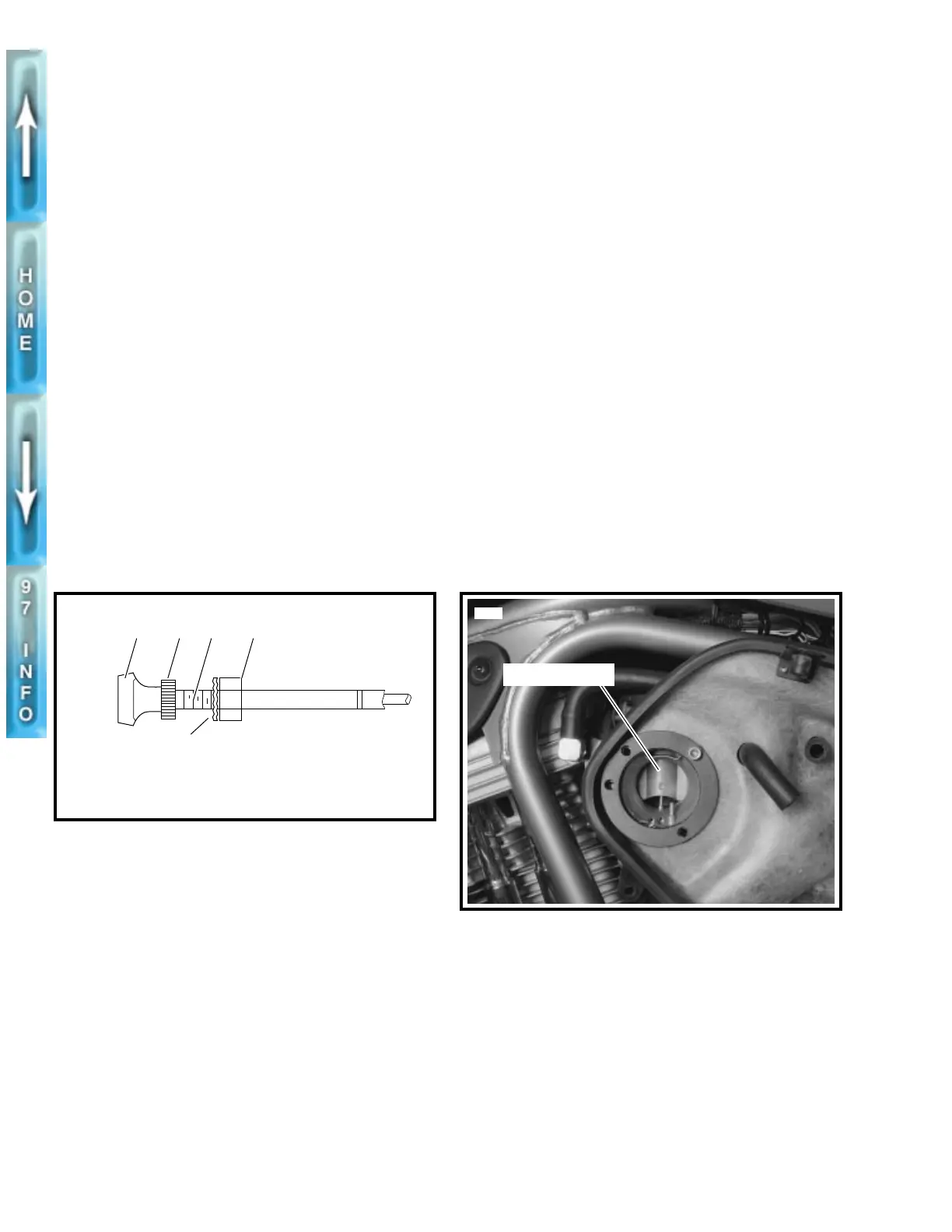

1. See Figure 4-10. Test vacuum piston as follows.

a. Remove air cleaner cover and snorkel.

b. Start engine running.

c. Twist throttle control partially open and closed sev-

eral times.

Observe whether or not vacuum piston has upward

movement. If piston does not rise, see VACUUM PIS-

TON ASSEMBLY TROUBLESHOOTING on page 4-4.

2. With engine not running, lift vacuum piston with finger.

Feel whether piston lifts fully and smoothly or whether

there is a binding condition.

Closing Malfunction

1. See Figure 4-10. With engine not running, lift vacuum

piston to full open position, then release. Observe

whether piston slides downward smoothly and fully to

stop.

2. Observe position of piston slide at its lowest downward

point. Lower edge of slide should rest at horizontal

groove at lower end of slide track. See VACUUM PIS-

TON ASSEMBLY TROUBLESHOOTING on page 4-4 if

problems are noted.

Figure 4-9. Fuel Enrichener Control

1. Enrichener knob

2. Plastic nut

3. Lockwasher

4. Flat

5. Hex nut

b0090c4x

21

3

4 5

Figure 4-10. Vacuum Piston

Vacuum piston

5679

Loading...

Loading...