5-15

1

CAUTION

Do not use sandpaper or emery cloth to remove burrs on

commutator. Otherwise, abrasive grit may remain on

commutator segments; this could lead to excessive

brush wear. Use only the recommended crocus cloth.

8. Check depth of mica on commutator. If undercut is less

than 0.008 in. (0.20 mm), use an undercutting machine

to undercut the mica to 1/32 in. (0.79 mm) deep. The

slots should then be cleaned to remove any dirt or cop-

per dust. See Figure 5-16. If an undercutting machine is

not available, undercutting can be done satisfactorily

using a thin hacksaw blade. After undercutting, lightly

sand the commutator with crocus cloth to remove any

burrs.

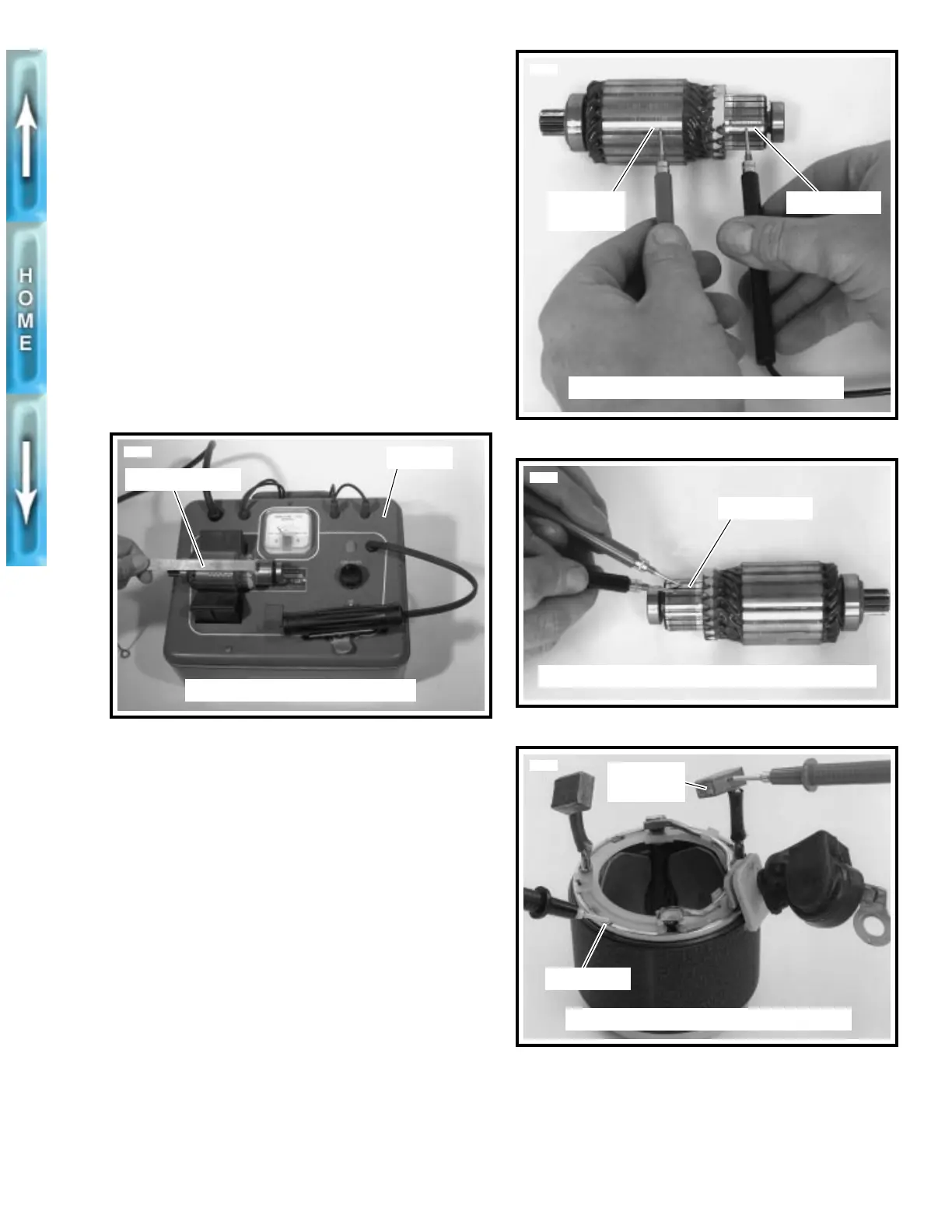

9. See Figure 5-17. Check for SHORTED ARMATURE with

a growler. Place armature on growler. Hold a thin steel

strip (hacksaw blade) against armature core and slowly

turn armature. A shorted armature will cause the steel

strip to vibrate and be attracted to the core. Replace

armatures if shorted.

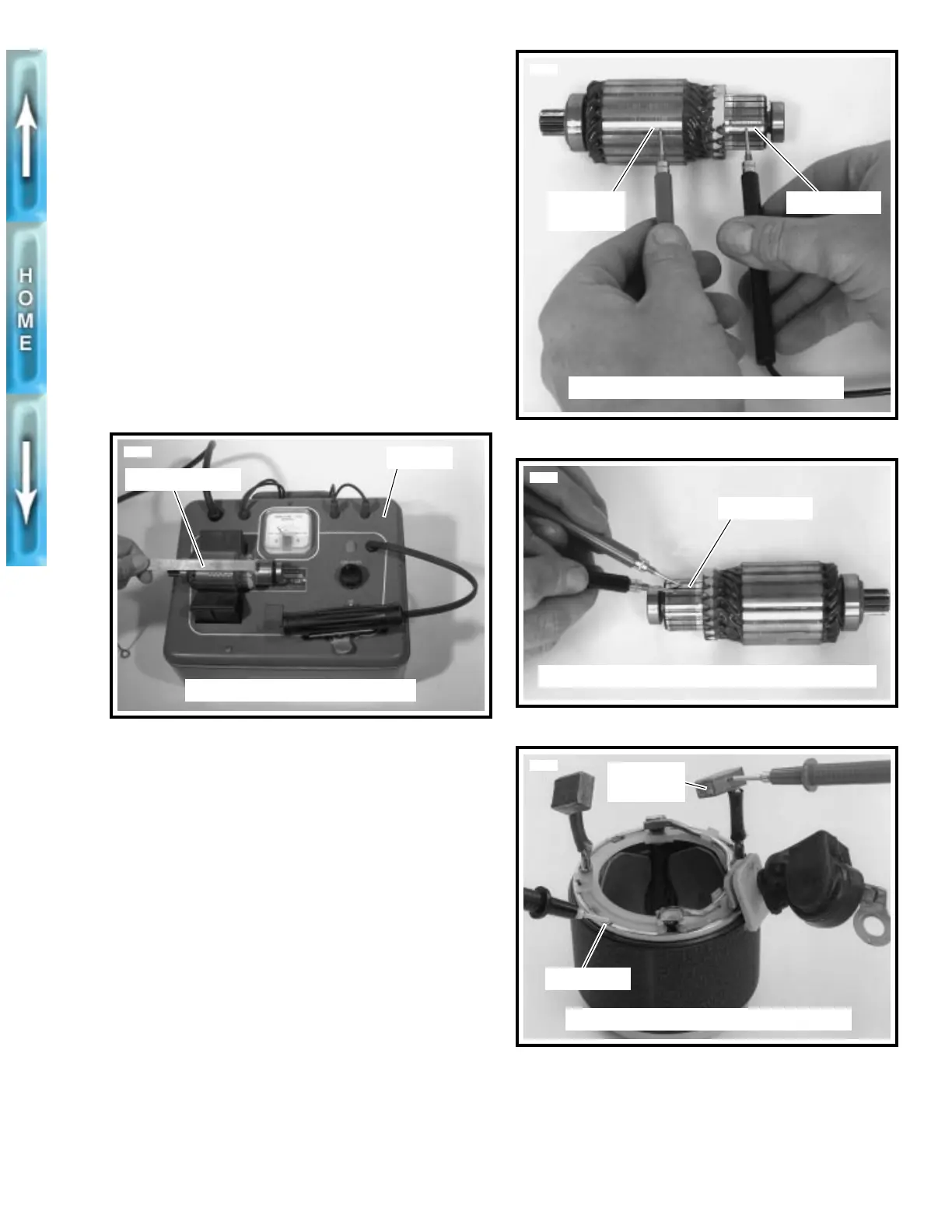

10. See Figure 5-18. Check for a GROUNDED ARMATURE

with an ohmmeter or continuity tester. Touch one probe

to any commutator segment. Touch the other probe to

the armature core. There should be no continuity (infinite

ohms). If there is continuity, then the armature is

grounded. Replace grounded armatures.

11. See Figure 5-19. Check for OPEN ARMATURE with an

ohmmeter or continuity tester. Check for continuity

between all commutator segments. There should be con-

tinuity (0 ohms) at all test points. No continuity at any test

point indicates armature is open and must be replaced.

12. See Figure 5-20. Check for GROUNDED FIELD COIL

with an ohmmeter or continuity tester. Touch one probe

to the frame. Touch the other probe to each of the

brushes attached to the field coil. There should be no

continuity (infinite ohms). If there is any continuity at

either brush, then the field coil(s) are grounded and the

field frame must be replaced.

Figure 5-17. Shorted Armature Test Using Growler

1782a

Thin steel strip

Replace armatures which vibrate

Growler

Figure 5-18. Grounded Armature Test

Figure 5-19. Open Armature Test

Figure 5-20. Grounded Field Test

Commutator

1783a

Replace armatures showing continuity

Armature

core

1784a

Replace armature if no continuity at any test point

Commutator

Replace field frames if continuity is found

Brush on

field coil

3542a

Field frame

Loading...

Loading...