1-21

REAR BELT DEFLECTION

INSPECTION

Check rear belt deflection:

● Inspect before every ride.

● Adjust at the 500 mile (800 km) service interval.

● Adjust at every 5000 mile (8000 km) service interval

thereafter.

The secondary drive belt should be checked for unusual

wear, cracking or loss of teeth. Check the belt sprocket for

unusual wear, broken teeth or damaged flange. When check-

ing deflection, have:

● No rider or cargo weight on motorcycle.

● Transmission in neutral.

● Belt and sprockets at room temperature.

● Motorcycle upright (not on side stand).

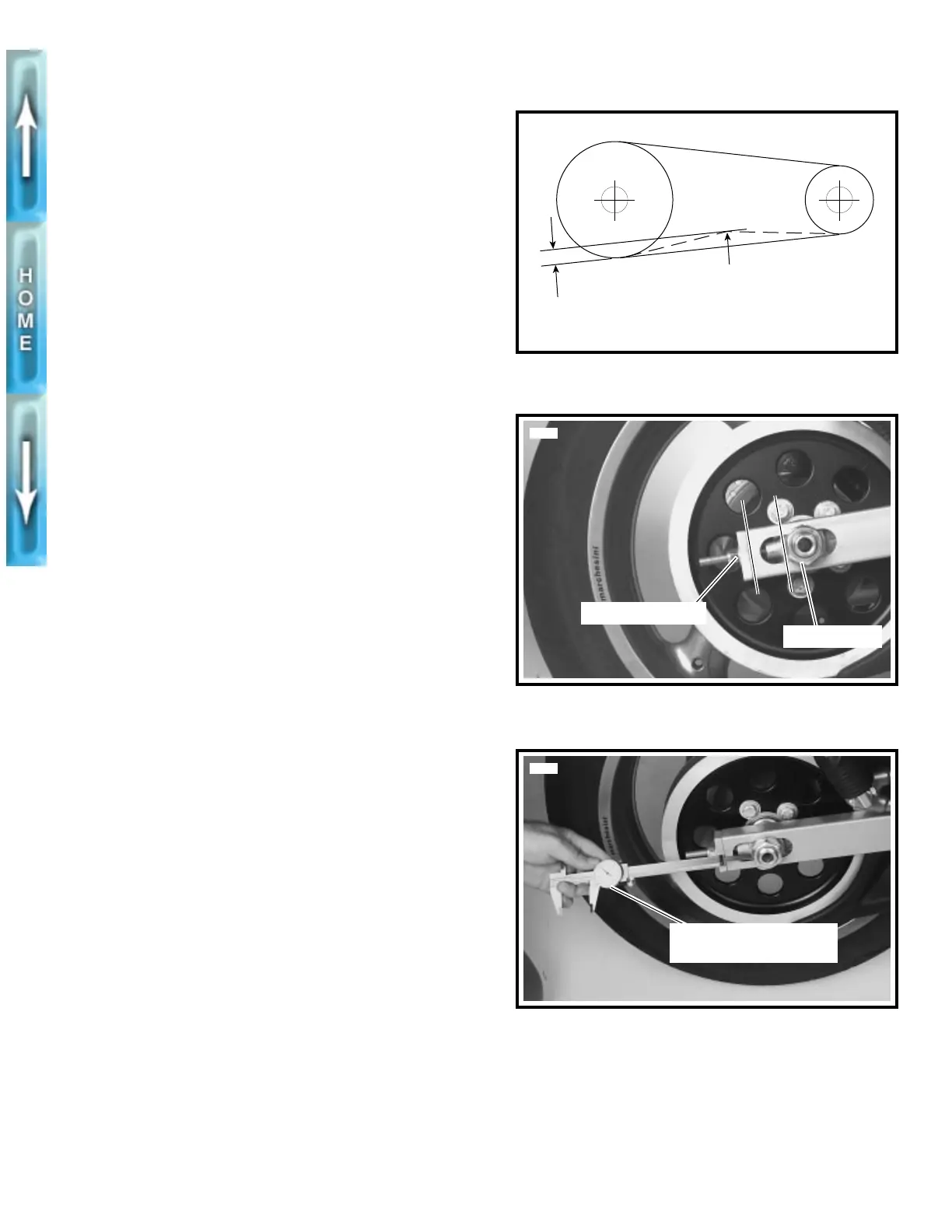

1. See Figure 1-21. At the lower strand, position “A”, mid-

way between transmission sprocket and rear wheel

sprocket, apply 10 Ibs (4.5 kg) of upward force on lower

span of rear belt using BELT TENSION GAUGE (Part No.

HD-35381).

2. Measure belt deflection “B” several times, each time with

belt moved (by rotating rear wheel) to a different position

on sprockets. With sprockets rotated to tightest belt posi-

tion, belt deflection “B” (measured at position “A”) should

be 7/8-1 in. (22.2-25.4 mm).

ADJUSTMENT

1. Adjust shock absorber spring preload. See REAR PRE-

LOAD ADJUSTMENT on page 1-23.

2. See Figure 1-22. Loosen rear axle nut (metric), if not

already performed.

NOTE

After you loosen the axle nut, turn the axle and nut so the rear-

most flat on each side is parallel with the ends of the swingarm.

Check to be sure rear wheel axle is parallel with swingarm

pivot shaft.

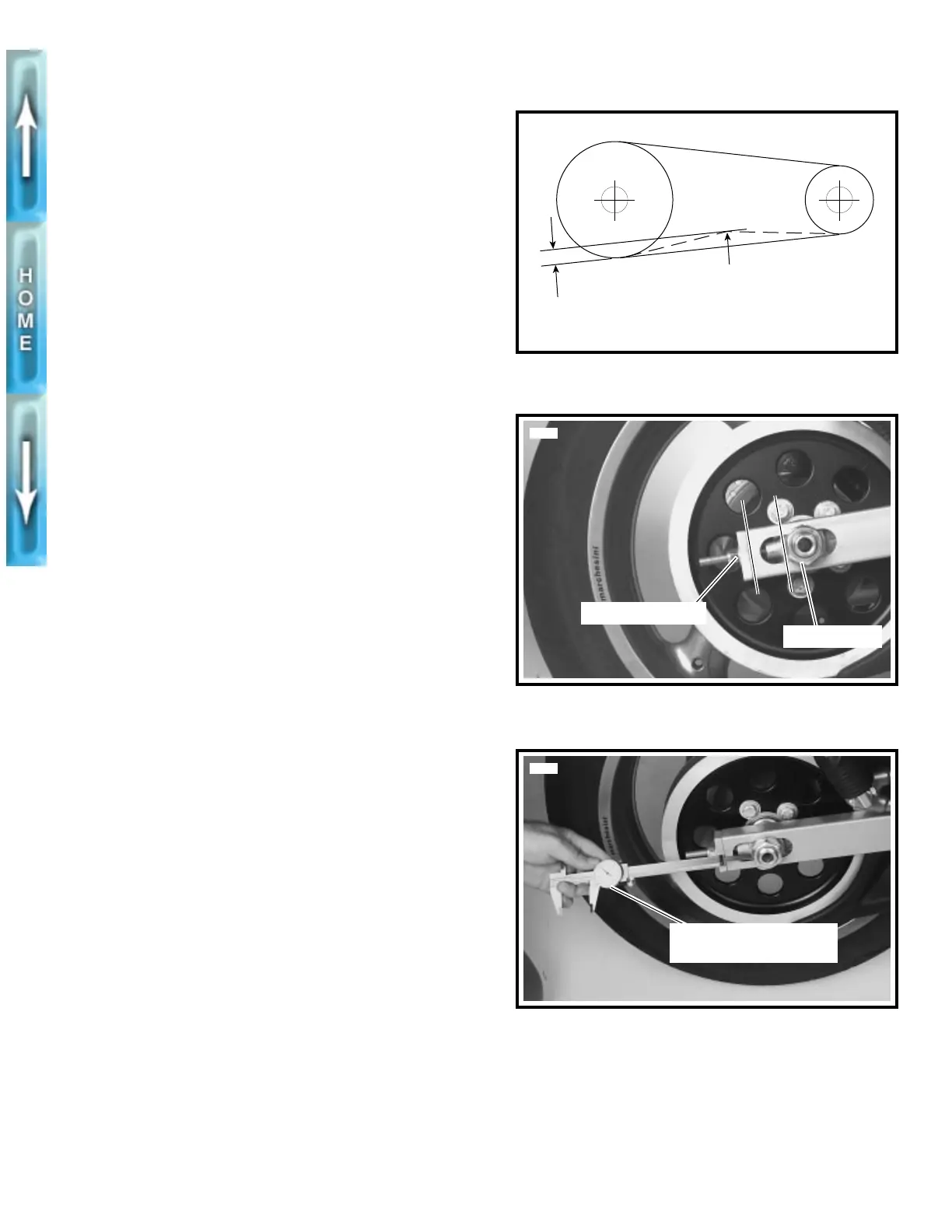

3. See Figure 1-23. Measure each side from the flat to the

end of the swingarm, to be sure rear axle is correctly

located.

4. Turn axle adjuster nuts (metric) on each side of swing-

arm to adjust belt deflection.

a. Turn clockwise to decrease deflection (increase ten-

sion).

b. Turn counterclockwise to increase belt deflection

(decrease tension).

Turn each adjuster nut exactly the same number of turns

to maintain rear wheel alignment

5. Tighten axle nut (metric) to 66-73 ft-lbs (89.5-98.9 Nm).

CLEANING

Keep dirt, grease, oil, and debris off the belt and sprockets.

Clean the belt with a rag which is slightly damp with light

cleaning agent.

Figure 1-21. Checking Belt Deflection

Figure 1-22. Rear Axle

Figure 1-23. Checking Rear Wheel Alignment,

Right Side Shown

B

A

b0086x6x

Apply 10 lbs (4.5 kg)

of upward force

Belt deflection should be

7/8-1 in. (22.2-25.4 mm)

Axle adjuster nut

Rear axle nut

5574

5585

Measure each side to

check wheel alignment

Loading...

Loading...