3) Connect a PC with LiteEdit to the controller and display "Values" window, group "Engine", value

W-TerminalFreq.

4) Select MAN mode and press the Start button to crank the gen-set. Make a note about the W

terminal frequency while the gen-set is cranking.

5) Press the Stop button to stop cranking.

6) Adjust the setpoint Start W Freq to a value twice that which you measured during cranking.

Oil pressure > Starting Oil P setpoint. The oil pressure is evaluated from the analog input 1 or

from the ECU if an ECU is configured.

At least one phase of generator voltage is >20% of nominal voltage.

These signals are used during start for powering down the starter motor even if still no RPM is

measured and also during stop in order to evaluate if the engine is really stopped.

3.11 Binary inputs

Use min. 1 mm

2

cables for wiring of binary inputs.

NOTE:

The name and function or alarm type for each binary input have to be assigned during the

configuration.

WIRING OF BINARY INPUTS

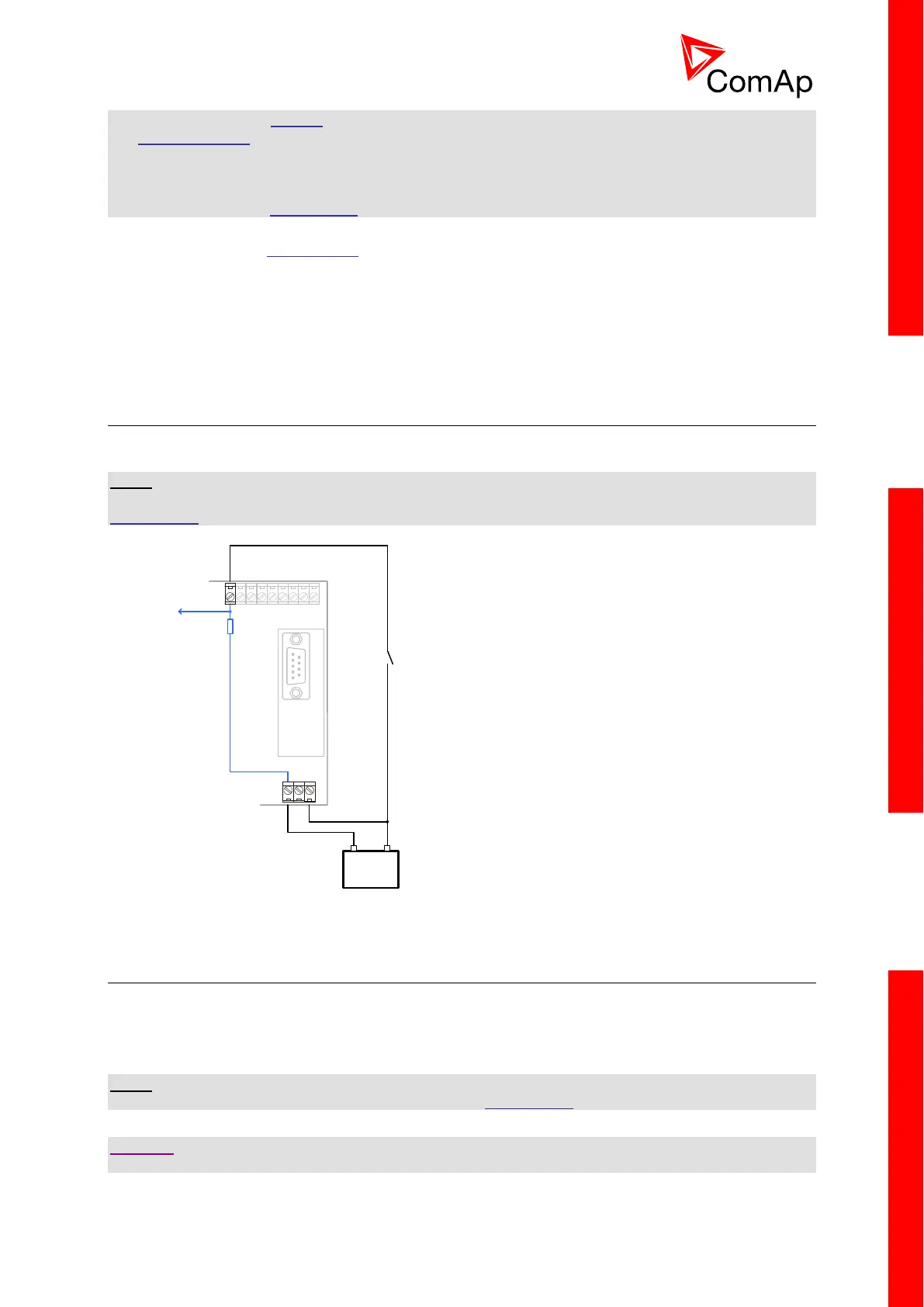

3.12 Binary outputs

Use min. 1 mm

2

cables for wiring of binary outputs. Use external relays as indicated on the schematic

below for all outputs except those where low-current loads are connected (signalization etc...).

NOTE:

The function of each output has to be assigned during configuration.

CAUTION!

Use suppression diodes on all relays and other inductive loads!

Loading...

Loading...