OPERATOR’S MANUAL

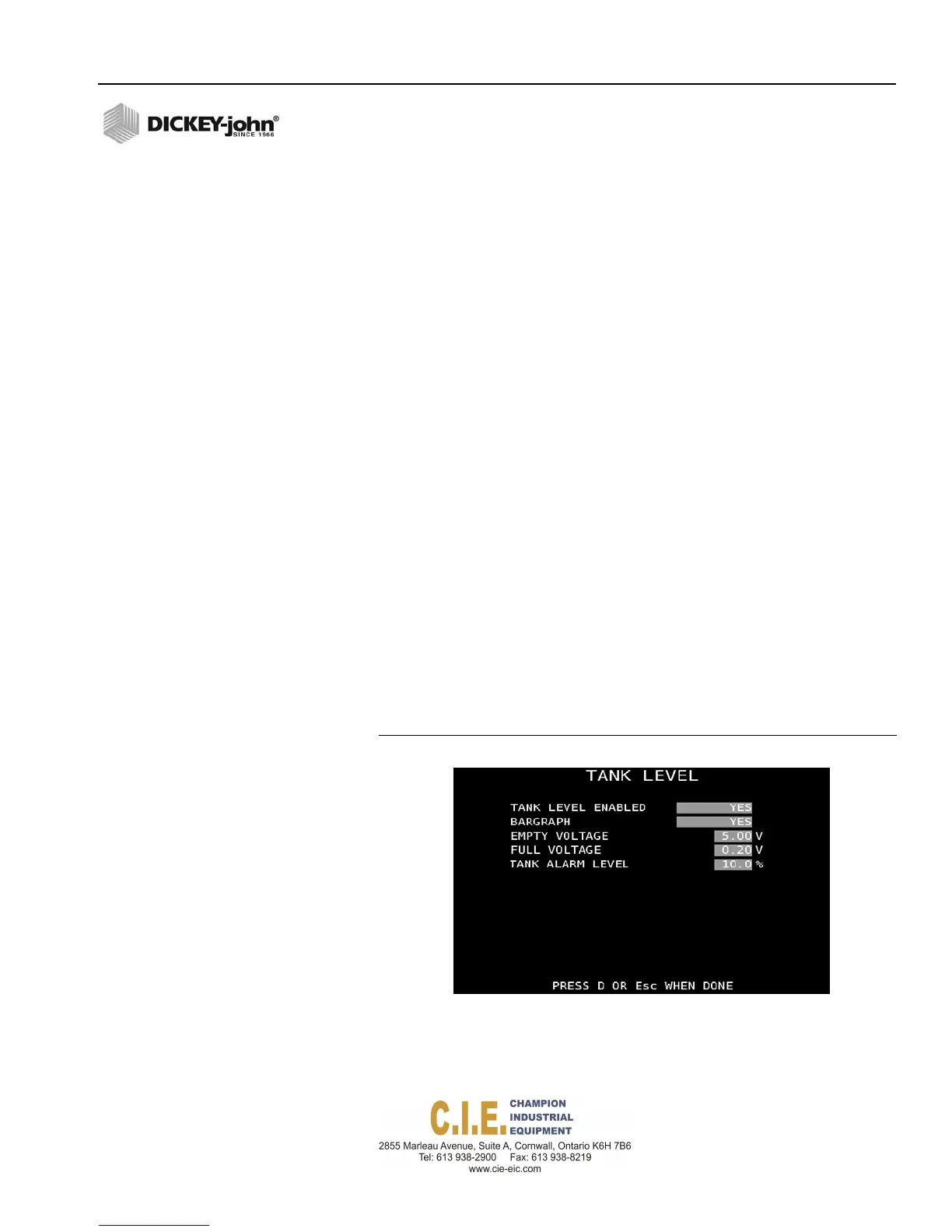

TANK LEVEL SENSOR CONFIGURATION

The tank level sensor monitors the liquid level for pre-wet or anti-ice

systems.

To enable the Tank Level Sensor:

1.

At the Tank Level Menu screen, select Yes at the Tank Level Enabled

input box.

2.

Tank level status can display in a bargraph format (Yes) or percentage

of approximate material remaining (No).

3.

Highlight the Empty Voltage input box. The tank must be empty before

performing the Empty Voltage calibration.

4.

Press “C” to capture the empty voltage reading.

5.

Fill tank to appropriate level. Highlight the Full Voltage input box. The

tank must be full before performing the Full Voltage calibration.

6.

Press “C” to capture the full voltage reading.

IMPORTANT: It is recommended that voltages are automatically

captured but manual entry of voltages can be entered.

7.

Enter a tank level alarm percentage to warn when the tank level has

reached the alarm limit. The value has a 5% hysteresis tolerance to

prevent random alarming due to varying tank levels while driving.

EXAMPLE: If the tank alarm is set for 10%, the alarm activates

when the level drops below 10% but will not clear until the level

reaches 15%. If the tank alarm is set for 100 gallons on a 1000

gallon capacity, the alarm activates when the level drops below 100

gallons but does not clear until the level reaches 150 gallons.

The alarm sounds for the first five seconds and text will flash until

the condition is cleared or another alarm sounds.

Figure 69

Tank Level Sensor

Flex4 Pro

TM

Control System

6010541 Rev A

SYSTEM PROGRAMMING / 77

PRESSCTOCAPTUREVOLTAGE

Loading...

Loading...