11. The Dynatest FWD/HWD Hardware

11.1 General Description

The Dynatest 8002 FWD and 8082 HWD are trailer mounted Falling Weight Deflectometers

of balanced and durable construction, having a low tongue load and a front supporting wheel.

A low centre of gravity ensures stable towing at highway speeds.

The drop weight guide shaft will be perpendicular to the road surface, if the tongue (i.e. centre

of towing ball) is kept in a height of 480-500 mm (19-20”) from the ground surface. The

loading plate is able to tilt up to 6 degrees (in any direction from a position perpendicular to

the guide shaft), as it is ball joint swivel suspended.

The impact of the drop weight is capable of producing impact loads essentially half-sine

waved in form, and having duration of between 25 and 30 msec. In addition, the drop weight /

buffer subassembly is furnished such that four different configurations of drop weight mass

can be used, all capable of producing the same 25 to 30 msec time of loading. Furthermore,

the weight can be released from a variable height, such that the peak load ranges for the four

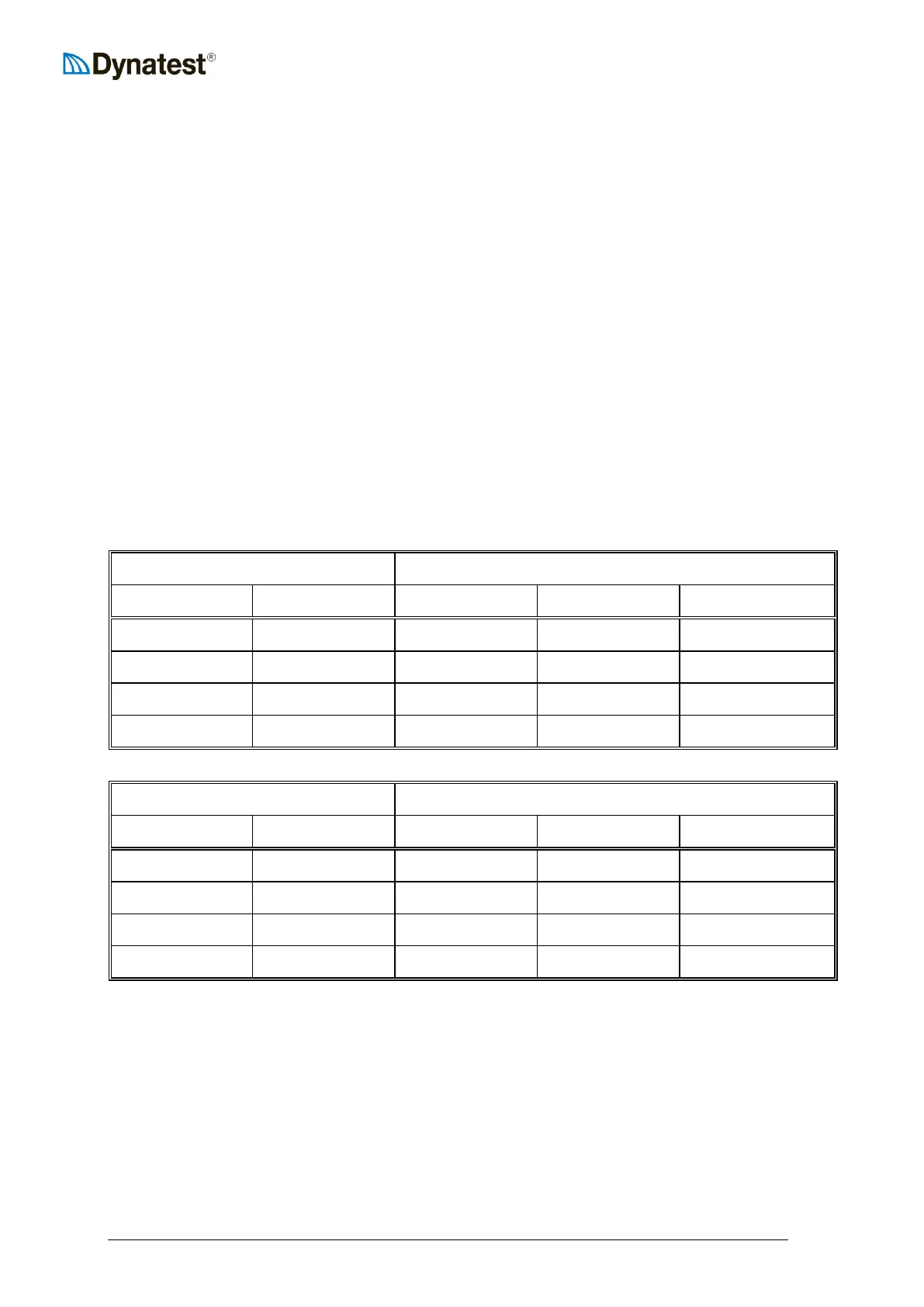

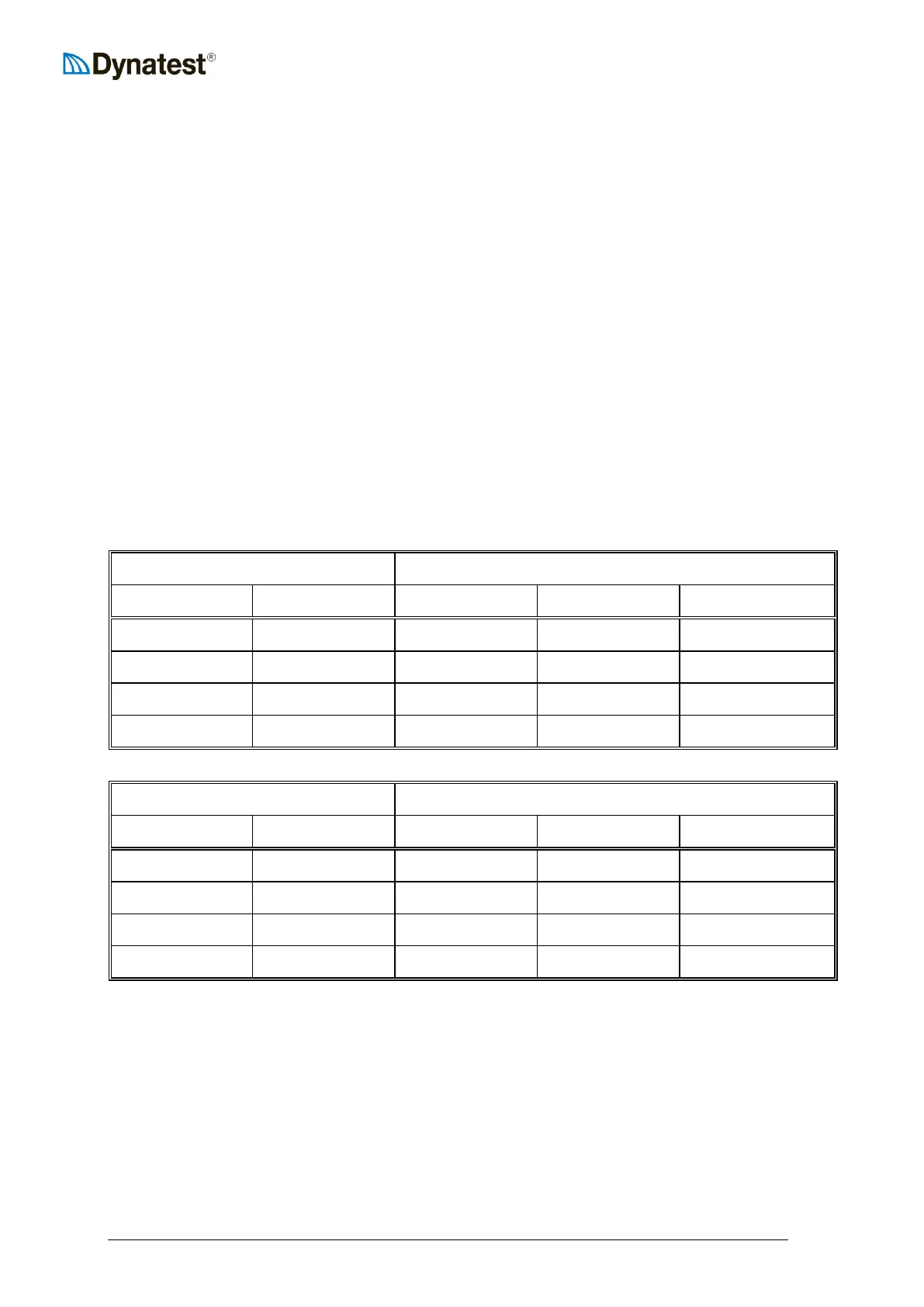

specified masses are produceable as follows:

Two loading plate sizes may be used, either the basic, 300 mm (11.8”) dia. plate or a 450 mm

(17.7”) dia. plate added below the basic plate. A rubber sheet is used to improve uniformity of

loading stress distribution over the whole loading plate area.

The unit is operated by means of a 12VDC electro-hydraulic system, powered from the

towing vehicle’s 12V electrical system (or from an optional, trailer mounted gasoline engine

driven Power Unit) via a heavy buffer battery setup (on the trailer).

Should the electro-hydraulic system fail to operate during a test, a mechanical jacking device

is furnished so the subassembly can be raised for removal of the equipment from the roadway.

Loading...

Loading...