30

Modbus TCP On-Board communications

POWERXL SERIES VFD MN040010EN—June 2018 www.eaton.com

Process data out 1 to 8

Process Data Out values 1 to 8 can be used in application

for various purposes. See below tables for additional

information.

Process data OUT (slave master)

The fieldbus master can read the VFD’s actual values using

process data variables. PowerXL Series applications use

process data as follows. These values are selectable via the

Fieldbus Process Data parameter group. These values would

correspond to the Modbus ID value. See Appendix A for

Parameter ID table showing values can be set.

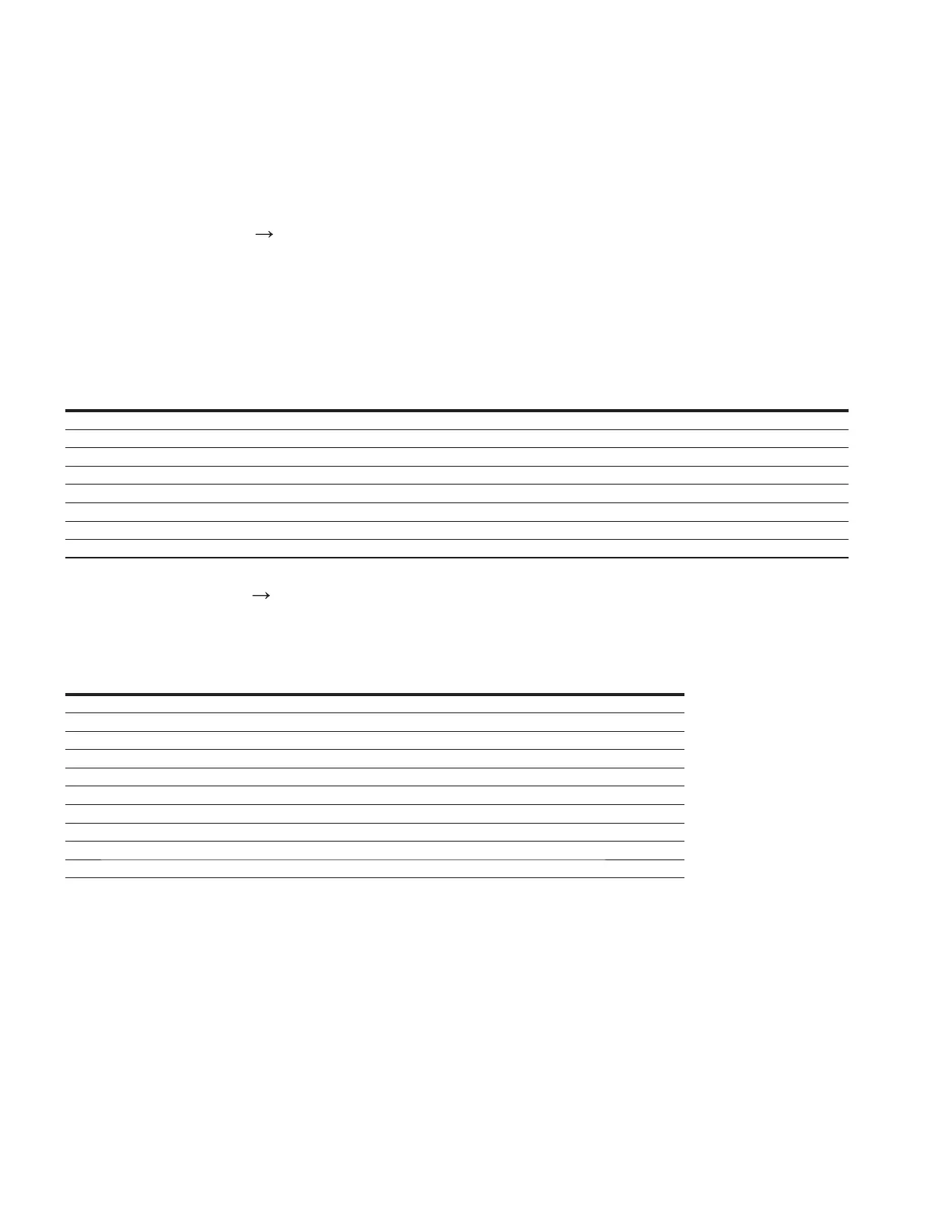

Table 54. Process data OUT

ID Data Value Default value Default para Unit Scale

2104

Process Data OUT 1 -32768–32767 1 Output Frequency Hz

2105

Process Data OUT 2 -32768–32767 2 Motor Speed RPM

2106

Process Data OUT 3 -32768–32767 3 Motor Current A

2107

Process Data OUT 4 -32768–32767 4 Motor Torque %

2108

Process Data OUT 5 -32768–32767 5 Motor Power %

2109

Process Data OUT 6 -32768–32767 6 Motor Voltage V

2110

Process Data OUT 7 -32768–32767 7 DC Link Voltage V

2111

Process Data OUT 8 -32768–32767 28 Latest Fault Code —

Process data IN (master slave)

Control Word, Reference and Process Data are used with All-in-One applications as follows.

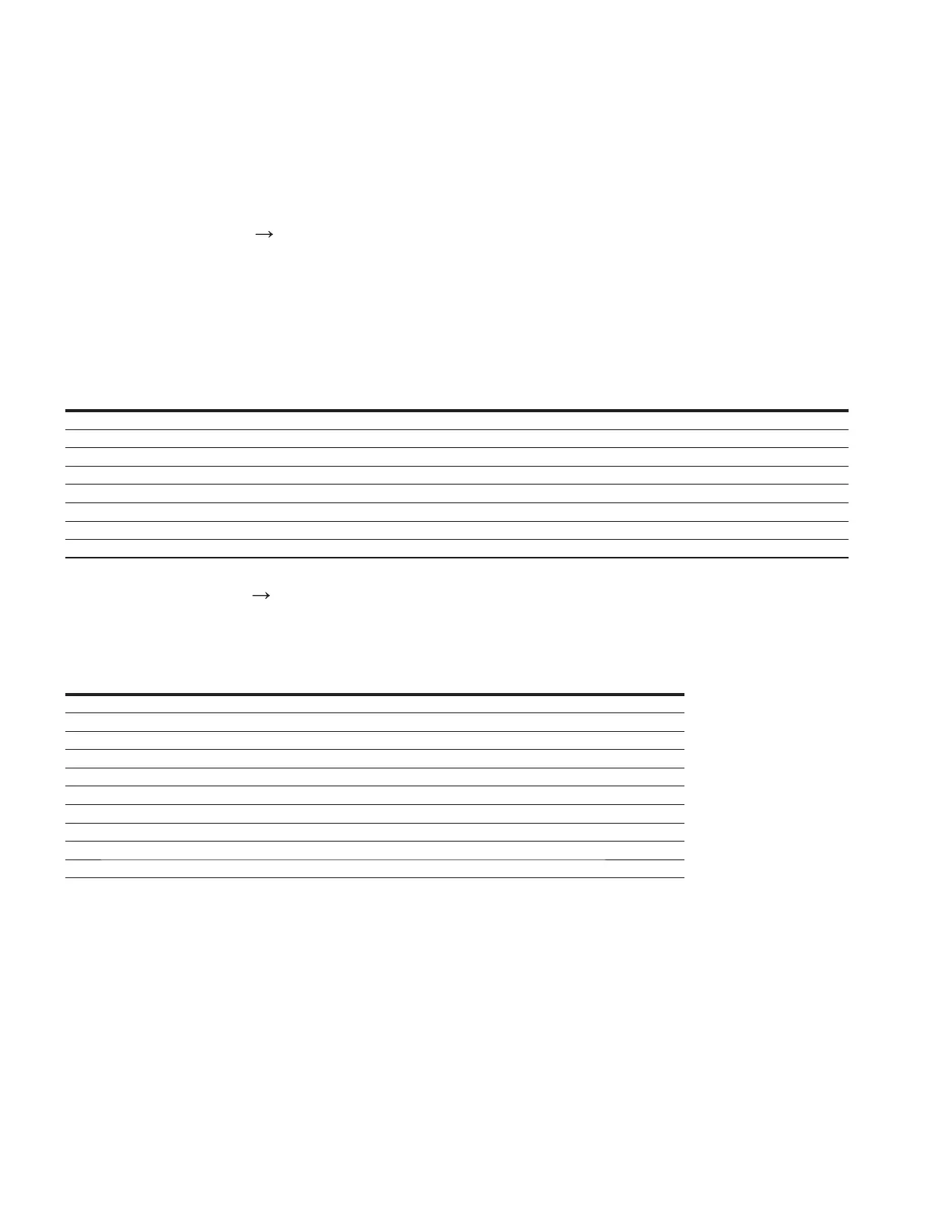

Table 55. Process data IN

ID Data Value Unit Scale

2003

Reference Speed Reference % 0.01

2001

Control Word — — —

2004

Process Data IN1

%0.01%

2005

Process Data IN2

%0.01%

2006

Process Data IN3

%0.01%

2007

Process Data IN4

%0.01%

2008

Process Data IN5

%0.01%

2009

Process Data IN6

%0.01%

2010

Process Data IN7

%0.01%

2011

Process Data IN8

%0.01%

Process Data IN1 through Process Data IN8 change based off the selected application.

See Appendix B for layout

Loading...

Loading...