84

Section F - Ice Maker

Rear Mounted Ice Maker

Theautomaticicemakerismountedinthefreezer

compartment.Itisattachedtoabracketextending

upfromthebackoftheaugermotorcover.

TheIceMakerisdesignedtoproduceice

automatically.Thelengthoftimebetweenharvest

cycleswillvary,dependingonloadconditions,

dooropenings,ambienttemperatureandfreezer

temperatureandwatertemperature.Thesefactors

mustbetakenintoconsiderationwhenchecking

theiceproductionrate.

Withatemperatureof-2°Fto+5°Finthefreezer,

therateofharvestwillbe40to96cubesper24

hourperiod.

Theicemakeriswiredacrossthelineandwill

harvesticeintherefrigerationordefrostcycles.

Thewatervalveandsolenoidassemblyareboth

mountedinthecompressorcompartment.

Atubeextendsfromthewatervalveuptherear

walloftherefrigeratortoawaterinletspoutthat

directsthewaterintothelltrough.Thewaterll

spoutwilltwistlockintoahousinginthebackofthe

refrigeratoranddirectwaterowintotheicemaker

fromthesideofthemold.

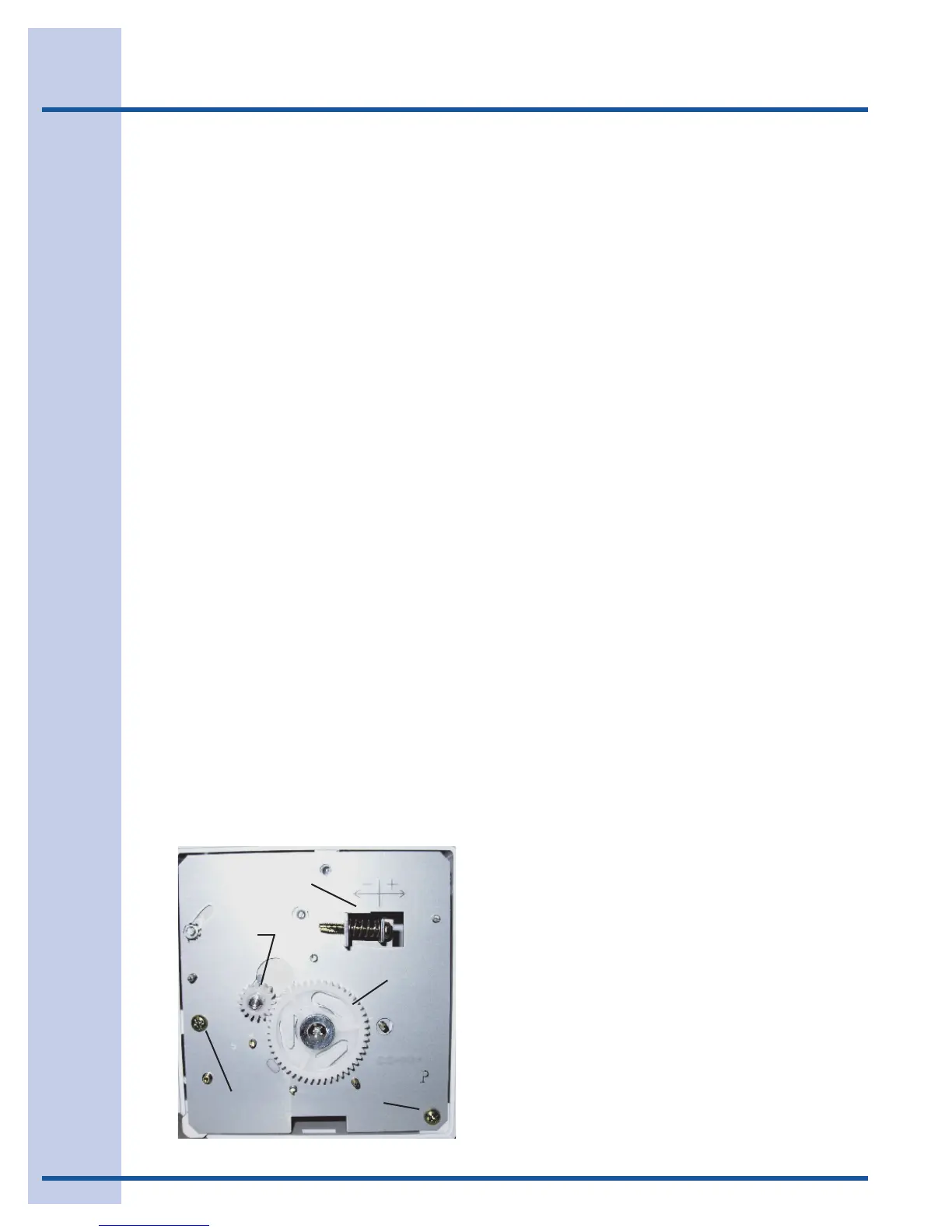

Front Cover (Figure F4)

Adecorativefrontcover,madeofmoldedplastic,

enclosestheoperatingmechanismoftheice

maker,protectingitfrommoisture.Itisessential

thatthecoverbeinplaceonanoperatingice

makertoprotectagainstpossiblecontactwiththe

mechanismbytheuser.(SeeFigureF1)

Figure F1

Ice Maker Components

Ice Mold (Figure F5)

Theicemoldisdie-castaluminumwiththeice

makerthermostatbondedtoitsfrontsurface.The

moldhasasemi-circularinteriorpartitionedinto

equalsizecompartments.Waterentersattheside

ofthemold,throughalltrough.Almofsilicon

greaseonthetopedgeofthemoldprevents

siphoningofwaterbycapillaryaction.

Mold Heater (Figure F6)

Amoldheater,ratedat112wattsat115volts,?

ohms±10%itiscoveredwithanaluminumsheath

andembeddedinthegroovedsectiononthe

undersideoftheIceMold.Whenthemoldheateris

energized,theicecontactsurfacewithinthemold

isheatedenoughtoallowharvestoftheicepieces.

ThemoldheateriswiredinserieswiththeIce

Makerthermostat,whichactsasasafetydevice.

Theheaterisstakedinplace,andisreplacedas

partoftheicemakerMold.

Athermalmasticsealerisplacedbetweenthe

heaterandthemoldtoensuregoodthermal

contact.

Ice Stripper (Figure F5)

AIceStripperisattachedtothemoldtopreventice

piecesfromfallingbackintothemold.Italsoserves

asadecorativesidecover.

Ice Ejector (Figure F5)

TheEjectorbladesaremoldedfromdelrin,and

extendfromacentralshaft,whichturnsinnylon

bearingsatthefrontandrear.Eachbladesweeps

anicesectionoutofthemold.Thedriveendof

theIceejectoris“D”shaped.FoodGradeSilicone

greaseisusedtolubricatethebearingsurfaces.

Water Valve Assembly

Thewatervalvesaresolenoidoperatedandwhen

energized,releaseswaterfromthewatertank

inthefooodcompartmentintotheIceMold.The

amountofwaterreleasedisdirectlyproportional

tothelengthoftimethewatervalveSwitchis

energized.Aowwasher,insidethewatervalve,

maintainsaconstantrateofwaterowovera

supplylinewithpressurerangingfrom20to100

psig.Itwillnotcompensateforpressuresbelow

20psig,orgreaterthan100psig.ANo.80-mesh

screen,placedaheadoftheowwasher,ltersout

foreignmaterials.

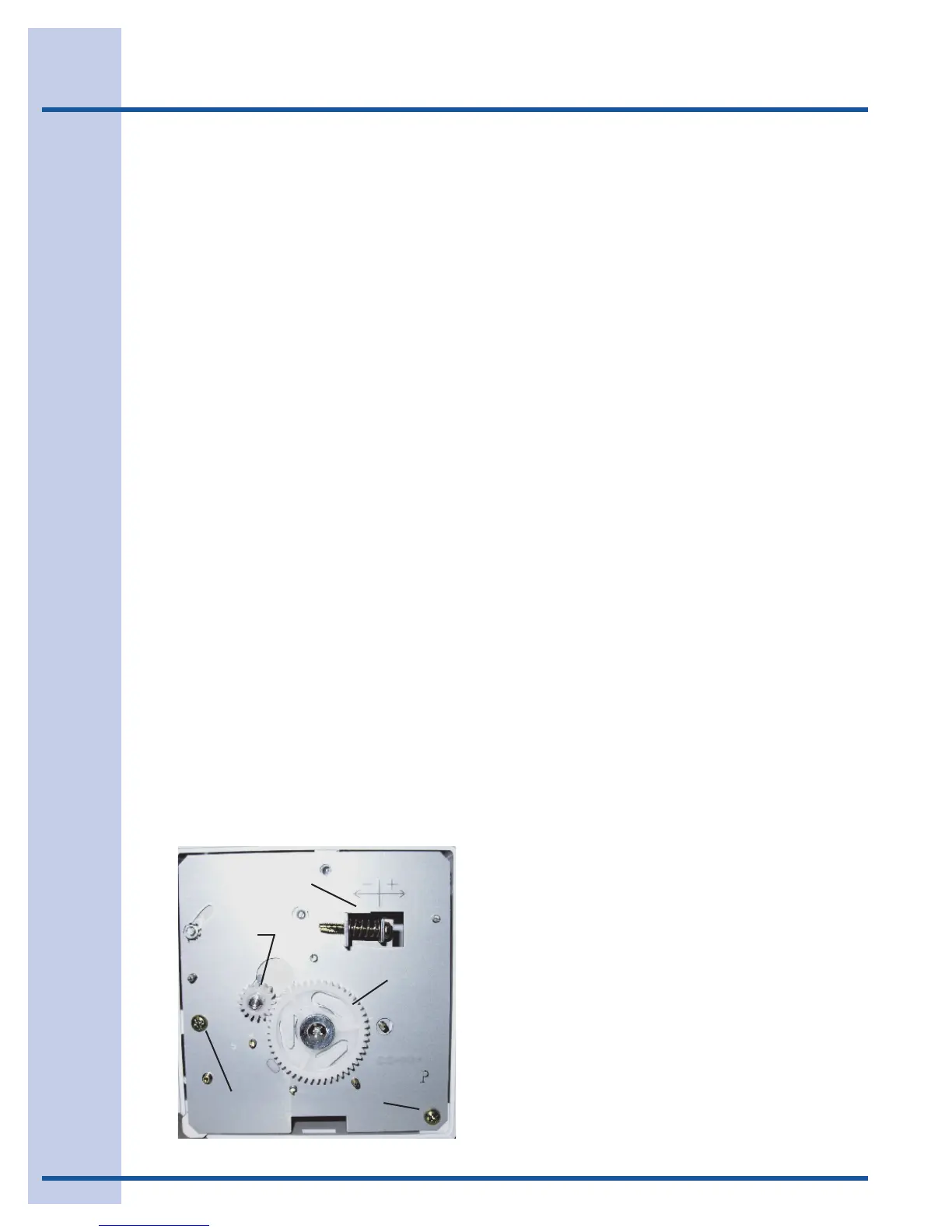

Mounting Plate Screw’s

Motor

Gear

Water Fill

Adjustment

Timing

Gear

Mounting Plate Front View

Loading...

Loading...