4900002277 J22 TDLAS Gas Analyzer

22 SpectraSensors, Inc.

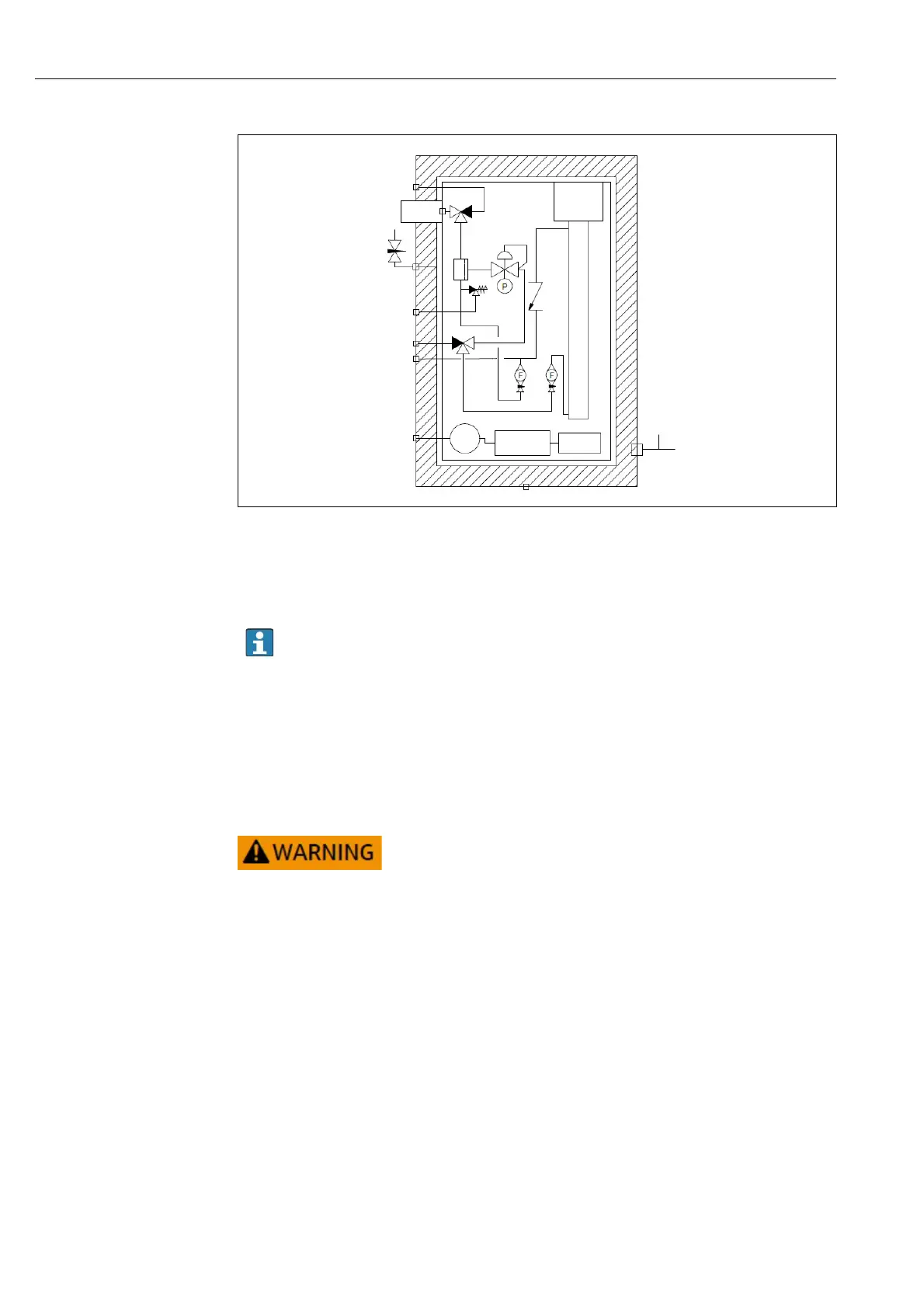

2: J22 TDLAS Gas Analyzer flow diagram - sample system

1 Pressure gauge

2 Sample supply valve (2- or 3-way)

3Flow meter

4Flow meter

For systems with an optional sample system enclosure purge, run purge before

start-up

→ page 133.

1. For systems with an enclosure, open the enclosure door.

2. Set the pressure gauge (1) to 69 to 103 kPa (10 to 15 psi).

3. Set the flow rate to 1 liter per minute and run the purge for at least 4 minutes

for safety, and until the moisture reading is below an acceptable error level.

4. Change the sample supply (2) valve to flow gas.

5. Position the validation/sample gas to open.

6. Set the pressure gauge (1) to setpoint.

• Do not exceed 172 kPa (25 psig) setting on the pressure

gauge.

• Do not exceed 345 kPa (50 psi) from the pressure reducing

station.

7. Adjust the left flow meter (3) to set point, then adjust the right flow meter

(4).

8. For systems with an enclosure, close the enclosure door.

Setting the J22 TDLAS Gas Analyzer address

The device address must always be configured for a Modbus server. The valid

device addresses are in the range from 1 to 247. Each address may only be

assigned once in a Modbus RS485 network. If an address is not configured

correctly, the measuring device is not recognized by the Modbus client. All

measuring devices are delivered from the factory with the device address 247

and with the "software addressing" address mode.

Loading...

Loading...