303

GEARCASE

GEARCASE REMOVAL AND INSTALLATION

13

Apply Gasket Sealing Compound to threads of the

gearcase retaining screws. Tighten the screws to

a torque of:

• 3/8 in. screws – 26 to 28 ft. lbs. (35 to 38 N·m)

• 7/16 in. screws – 40 to 50 ft. lbs. (54 to 68 N·m)

Apply Gasket Sealing Compound to threads of the

trim tab screw. Install gasket on “M”-type gear-

cases. Install and align the trim tab (cover on “L”-

type) with the index marks noted prior to disas-

sembly. Tighten the trim tab screw to a torque of

35 to 40 ft. lbs. (47 to 54 N·m). For adjustment,

refer to Trim Tab Adjustment on p. 70.

IMPORTANT: Standard rotation and counter

rotation trim tabs must not be interchanged. This

would result in inadequate cooling water supply to

the propeller hub.

Place the shift rod in the shift rod lever. Install the

retaining pin and washer. Tighten pin to a torque

of 60 to 84 in. lbs. (7 to 9.5 N·m).

IMPORTANT: During break-in period of a reas-

sembled gearcase, change the gearcase lubricant

between 10 to 20 hours of operation.

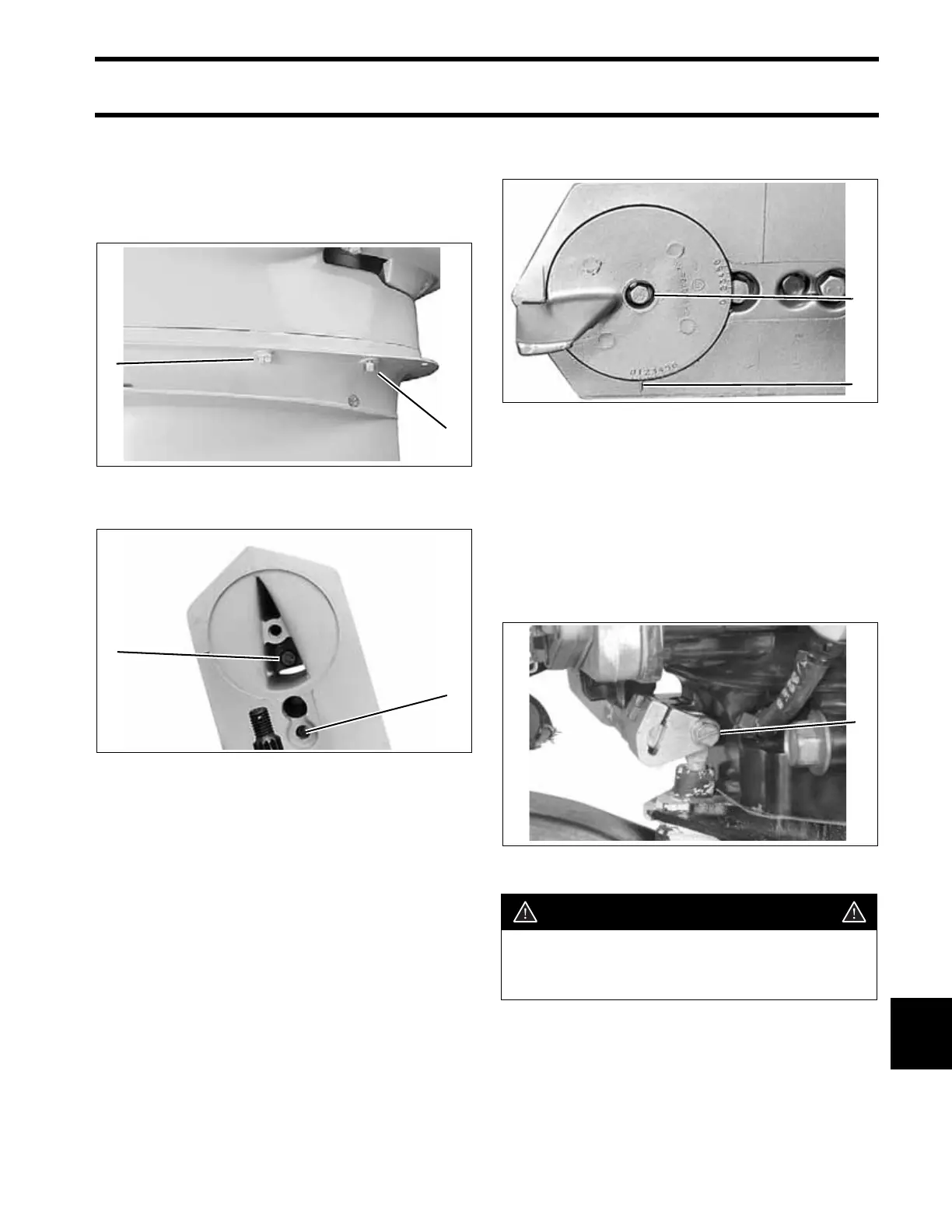

1. Alignment screw

2. 3/8 in. screw

005403

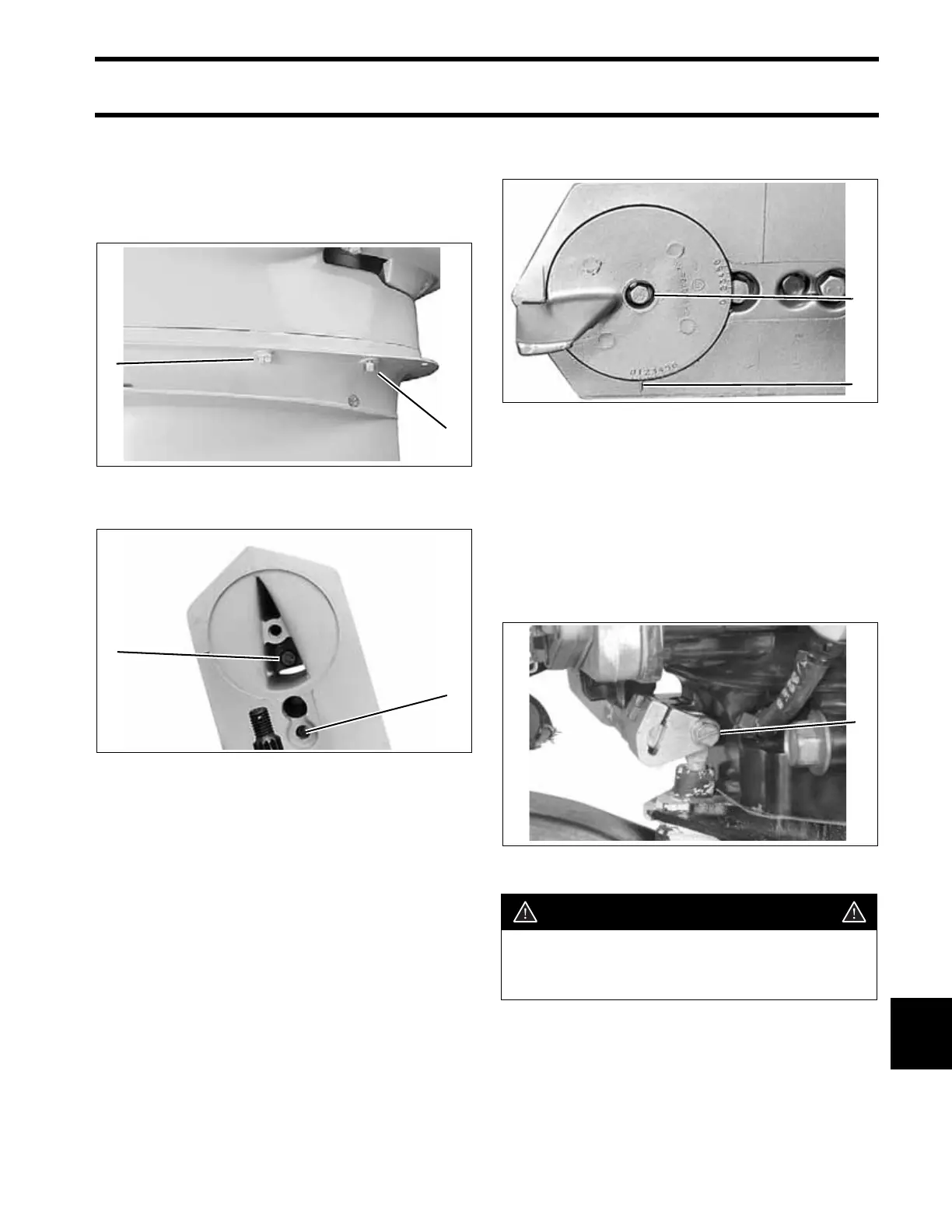

1. 7/16 in. screw

2. 3/8 in screw

COA3139

1

2

1

2

1. Trim tab screw

2. Index mark

COA3663

1. Shift rod screw 004241

WARNING

To prevent loss of operator control, check

for proper shifting operation and adjust, if

necessary.

1

2

1

Loading...

Loading...