5.4 Details of Function Codes

5-243

Details of

Function Codes

F codes

E codes

C codes

P codes

H codes

A codes

b codes

r codes

J codes

d21 to d35

U codes

y codes

Chapter 5 Function Code

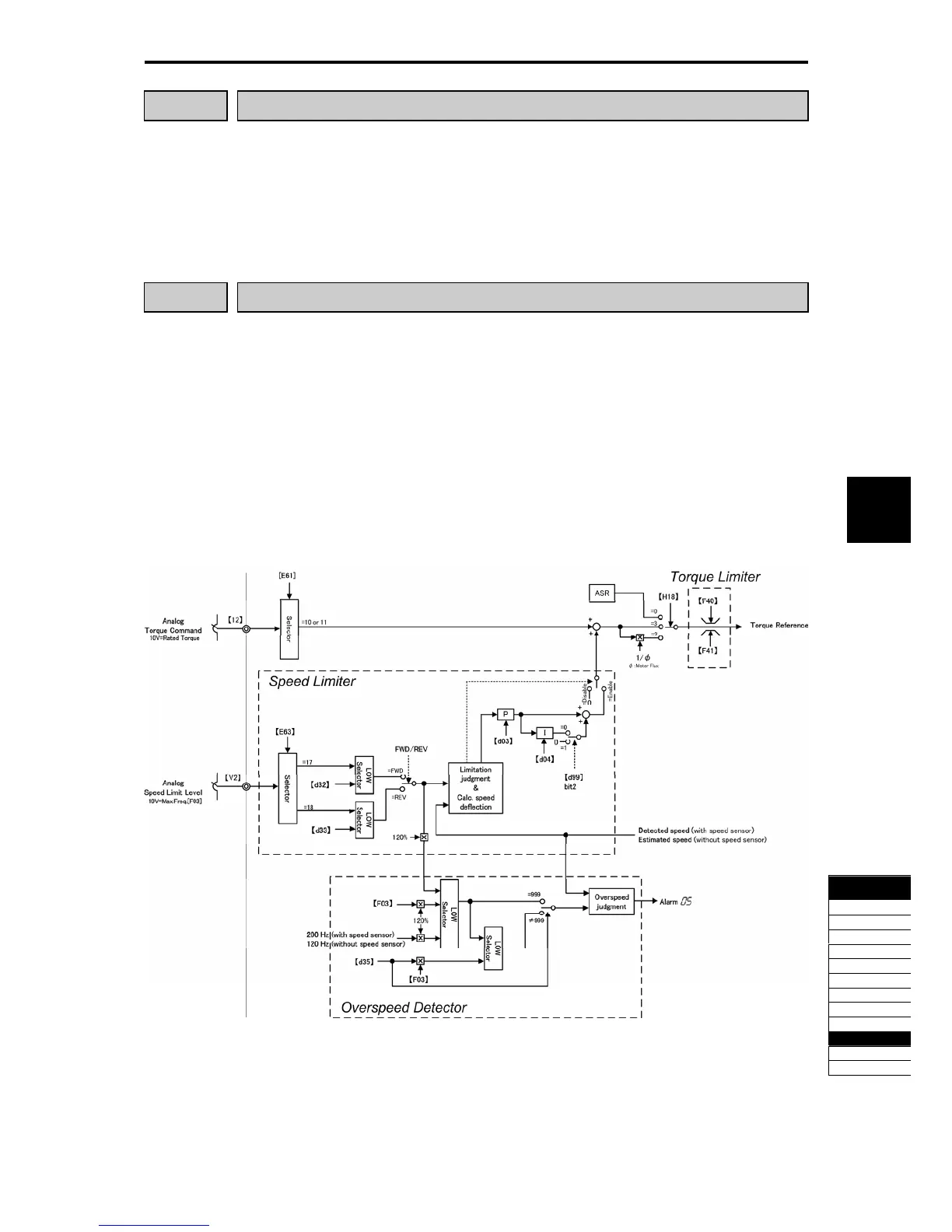

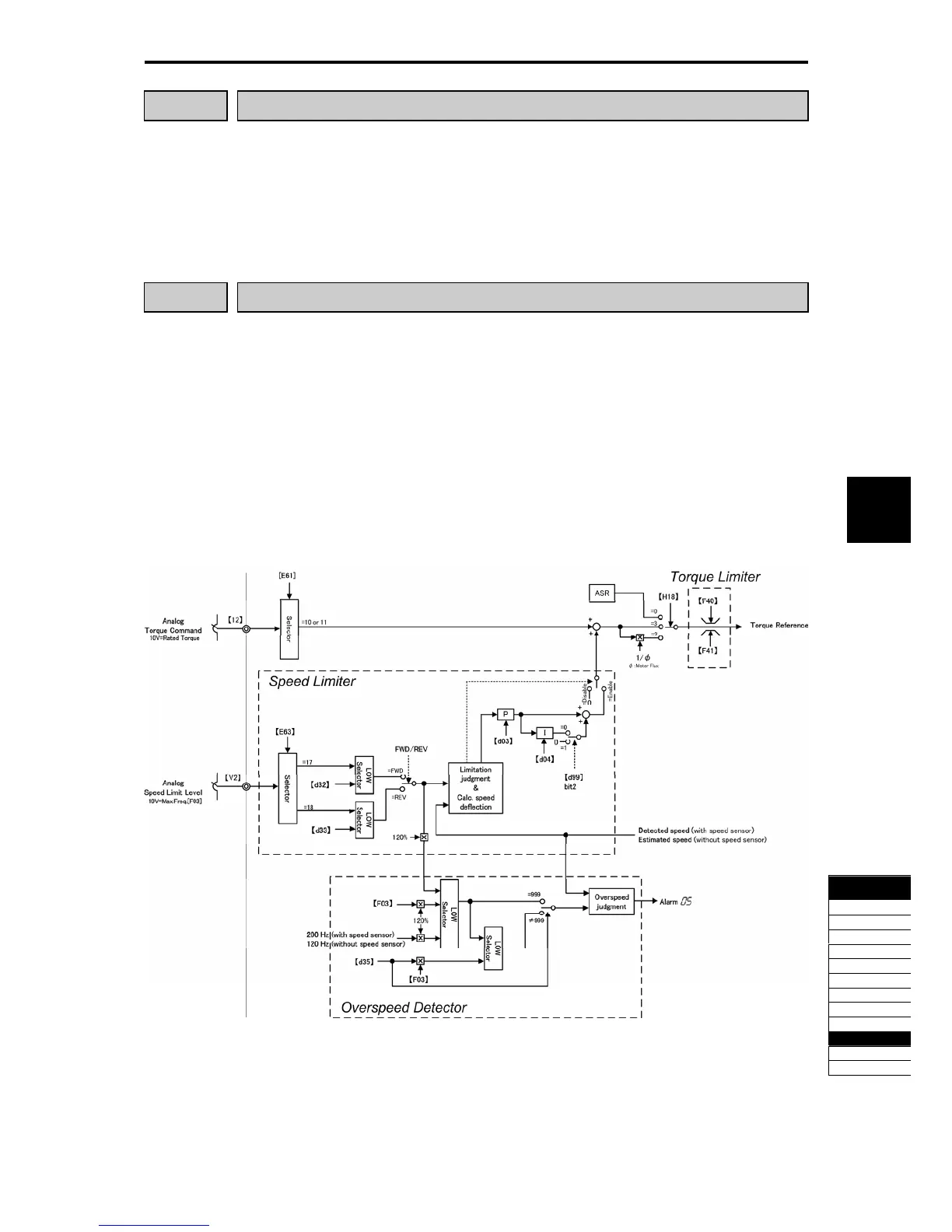

d32, d33

Torque Control (Speed Limit 1, Speed Limit 2)

There are cases that the motor unexpectedly starts rotating in high speed due to the regenerative load in

droop control (which is not generated usually) or due to the incorrect setting of the function code. In order to

protect the machinery, the overspeed level can be freely set.

- Forward overspeed level = Maximum output frequency (F03) x Speed limit 1 (d32) x 120 (%)

- Reverse overspeed level = Maximum output frequency (F03) x Speed limit 2 (d33) x 120 (%)

d35

Overspeed Detect Level

The overspeed detect level by the torque control can be set by using d35. The overspeed detect level is set

in percentage to the maximum output frequency (F03, A01, b01, r01).

When the following conditions are established, the inverter judges the overspeed condition and outputs

0s

alarm.

Motor speed

≥ Max. output frequency (F03/A01/b01/r01) x d35

When "999" is set, the inverter outputs

0s

alarm under the following conventional conditions.

Motor speed

≥ Max. output frequency (F03/A01/b01/r01) x (d32 or d33) x 1.2

Or

Motor speed

≥ 200 Hz (vector control with speed sensor) or 120 Hz (vector control without speed sensor)

x (d32 or d33) x 1.2

Fig.5.4-124 Torque control block drawing

Loading...

Loading...