AT600 User’s Manual 7

Chapter 2. Installation

2.4 Installing the Clamp-on Fixture And Transducer System

2.4.1 Clamp-on Fixture and Transducer Location

For a given fluid and pipe, the accuracy of AT600 depends on the location and alignment of the transducers. In addition

to accessibility, when planning for transducer location, adhere to the following guidelines:

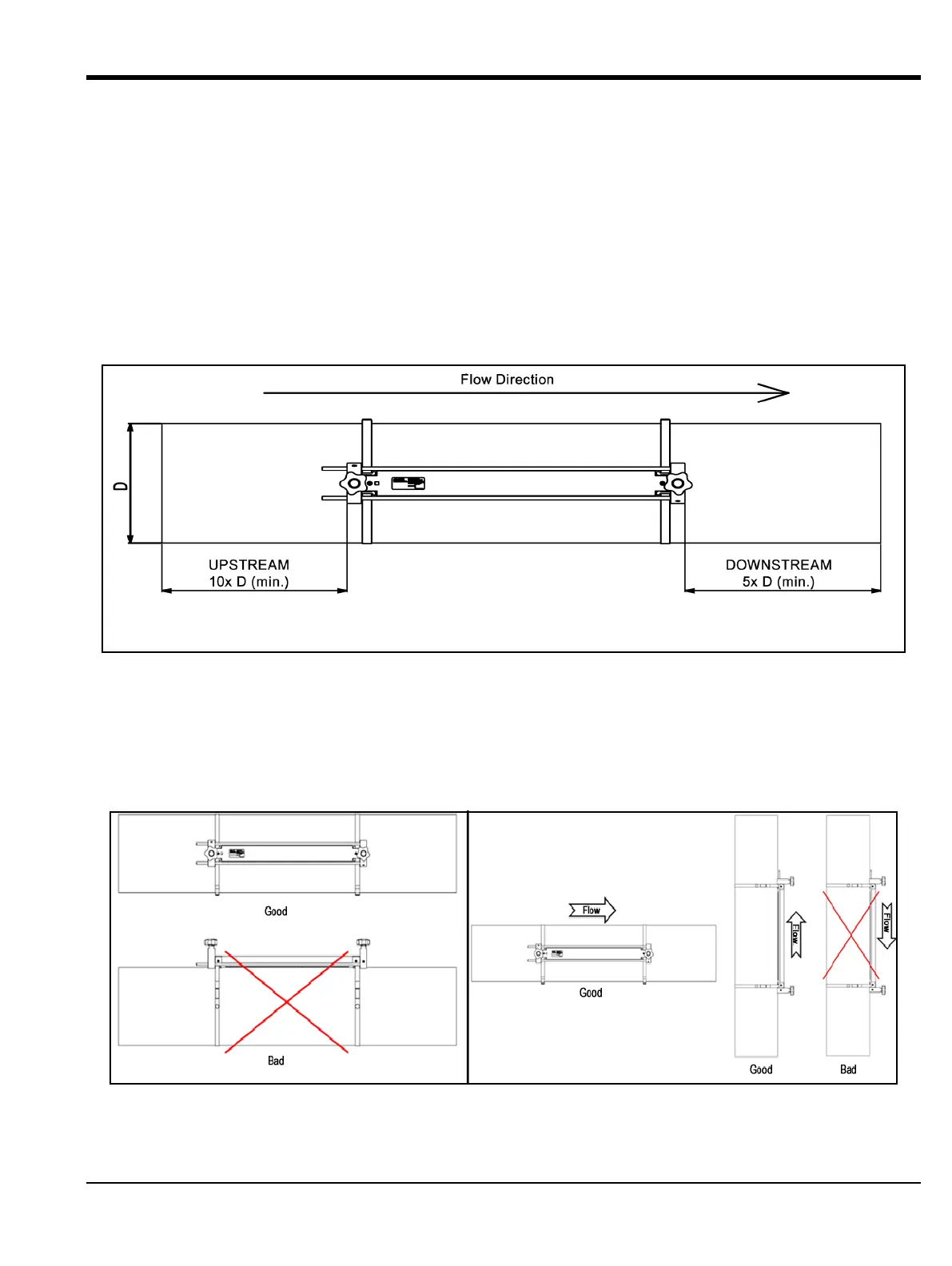

• Locate the clamp-on fixture and transducer system so that there are at least 10 pipe diameters of straight,

undisturbed flow upstream and 5 pipe diameters of straight, undisturbed flow downstream from the measurement

point. Undisturbed flow means avoiding sources of turbulence in the fluid such as valves, flanges, expansions, and

elbows; avoiding swirl; and avoiding cavitation.

Figure 7: AT600 Transducer Location

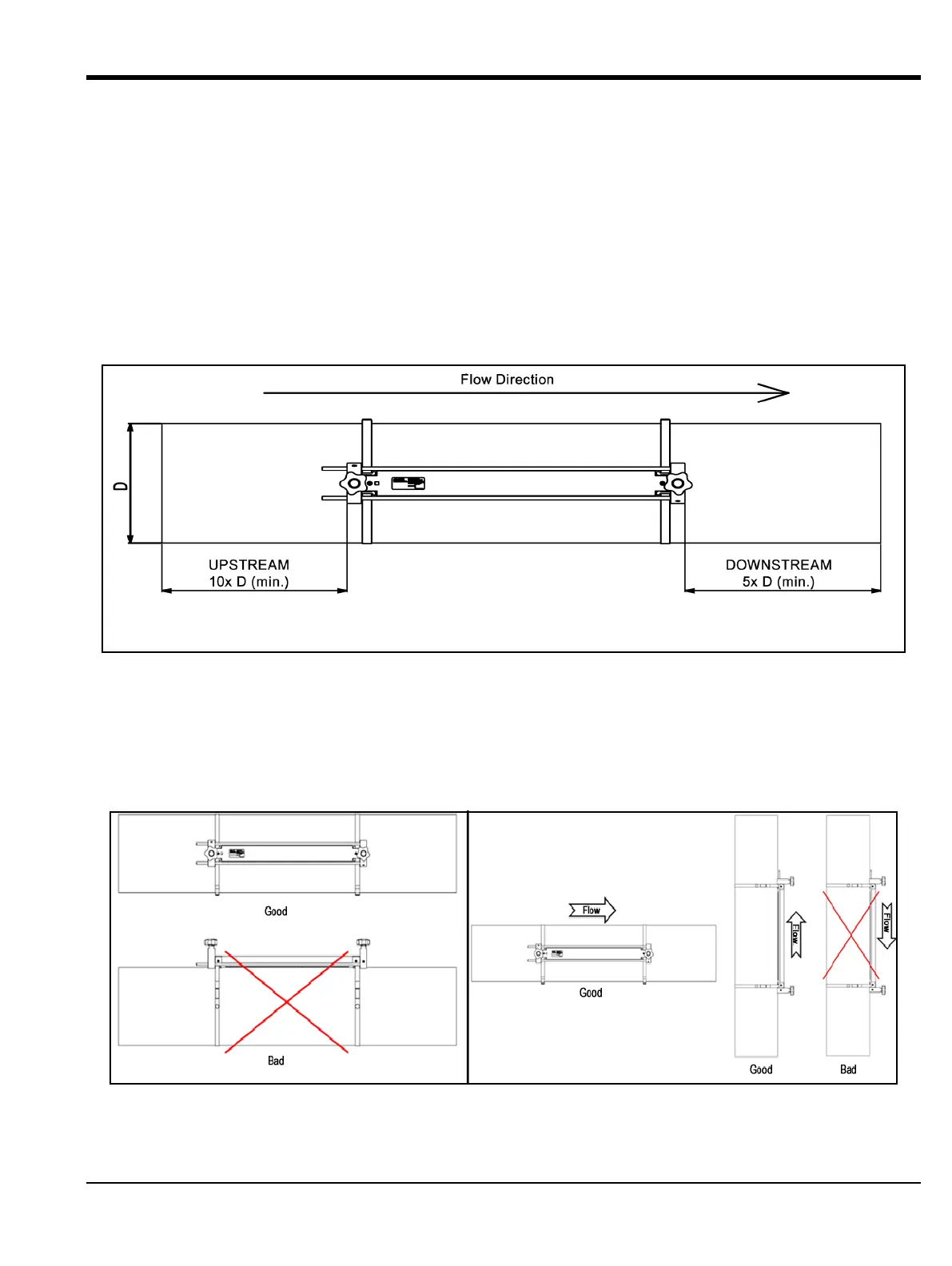

• Locate the transducers on a common axial plane along the pipe. Locate the transducers on the side of the pipe,

rather than the top or bottom, since the top of the pipe tends to accumulate gas and the bottom tends to accumulate

sediment. Either condition will cause increased attenuation of the ultrasonic signal. There is no similar restriction

with vertical pipes as long as the flow of fluids is upward to prevent free falling of the fluid of a less than full pipe.

Figure 8: Good and Bad Transducer Location

Loading...

Loading...