4 – 2

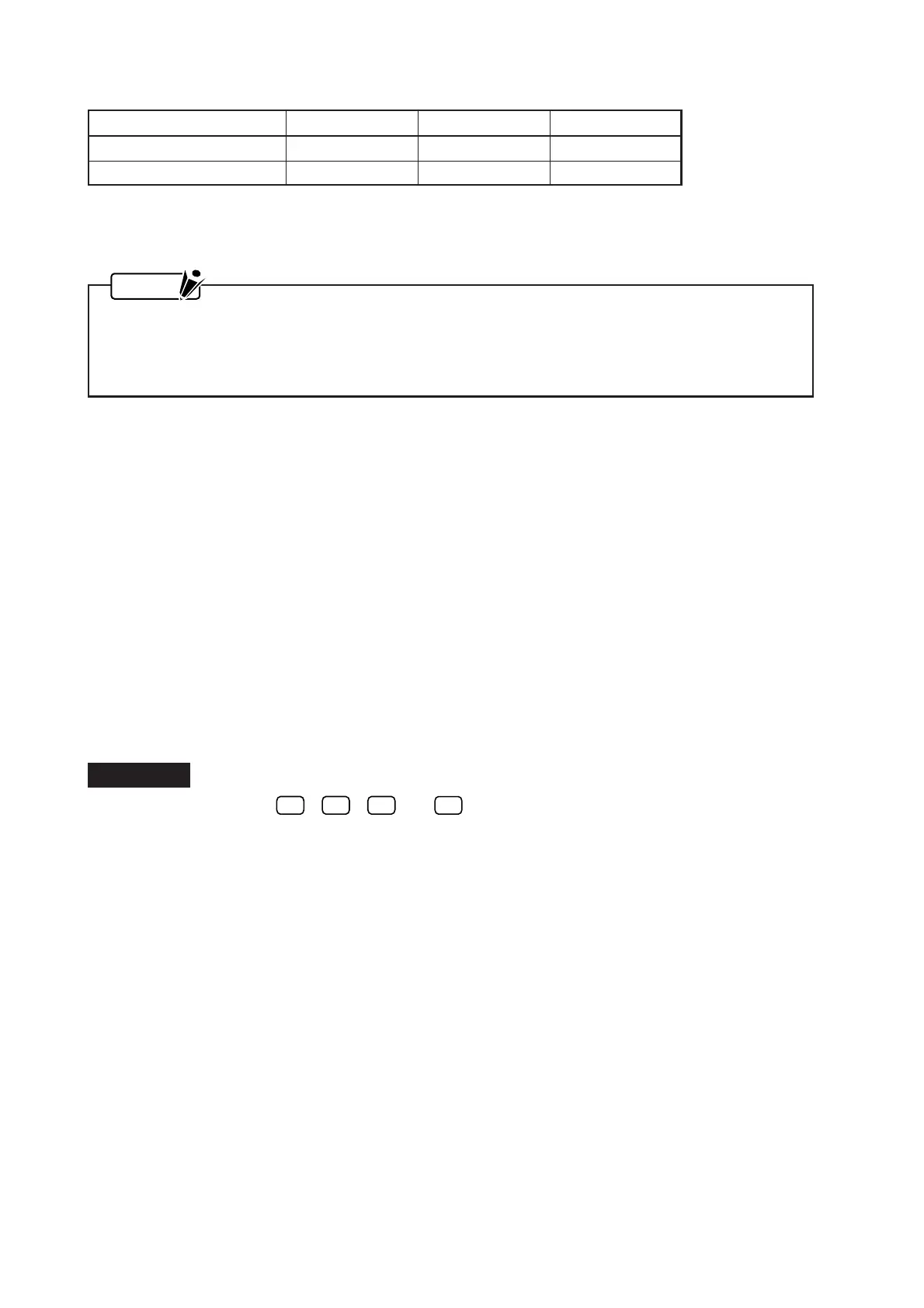

Reference Values for Plotting Conditions

Pen type FORCE SPEED QUALITY

Water-based ballpoint pen 20 to 23 40 2 to 3

Oil-based ballpoint pen 18 to 23 40 2 to 3

To avoid unnecessary wear on the pen’s tip, specify the FORCE value to its lowest permissible

setting. When specifying the SPEED value, check that the plotted results are not too faint or

otherwise unsatisfactory.

NOTE

• Raising the SPEED and QUALITY settings results in a coarser finish but shortens the overall

cutting/plotting time.

• Lowering the SPEED and QUALITY settings results in a finer finish but lengthens the overall

cutting/plotting time.

Precautions on Cutting Rubber for Sandblasting

(1) The amount of rubber that can be cut in one session varies with the characteristics of the medium

(thickness, hardness, and weight) and the pattern to be cut. Use the medium that will actually be cut to

alternately adjust the cutting conditions and run a cutting test.

(2) If the rubber tends to curl, rubber that has been cut may come loose and contact the travelling cutter

blade, thereby preventing the starting and end points of cutting from accurately matching.

4.2 Selecting a Set of Cutting Conditions

Four different sets of user-defined cutting conditions can be registered in the plotter’s memory as COND

Nos. 1 through 4. To specify a set of cutting conditions, you must first select the destination COND No. By

selecting a different COND No., you can easily switch between pre-defined cutting conditions for four types

of media.

Procedure

(1) Press a function key (

F1

,

F2

,

F3

,or

F4

) to select a pre-defined set of cutting conditions of

the corresponding number.

(2) The selected set of cutting conditions are loaded to the plotter and become the currently selected

cutting conditions.

Loading...

Loading...