78

Saw-Spindle Moulder

B3 / B3 e-classic

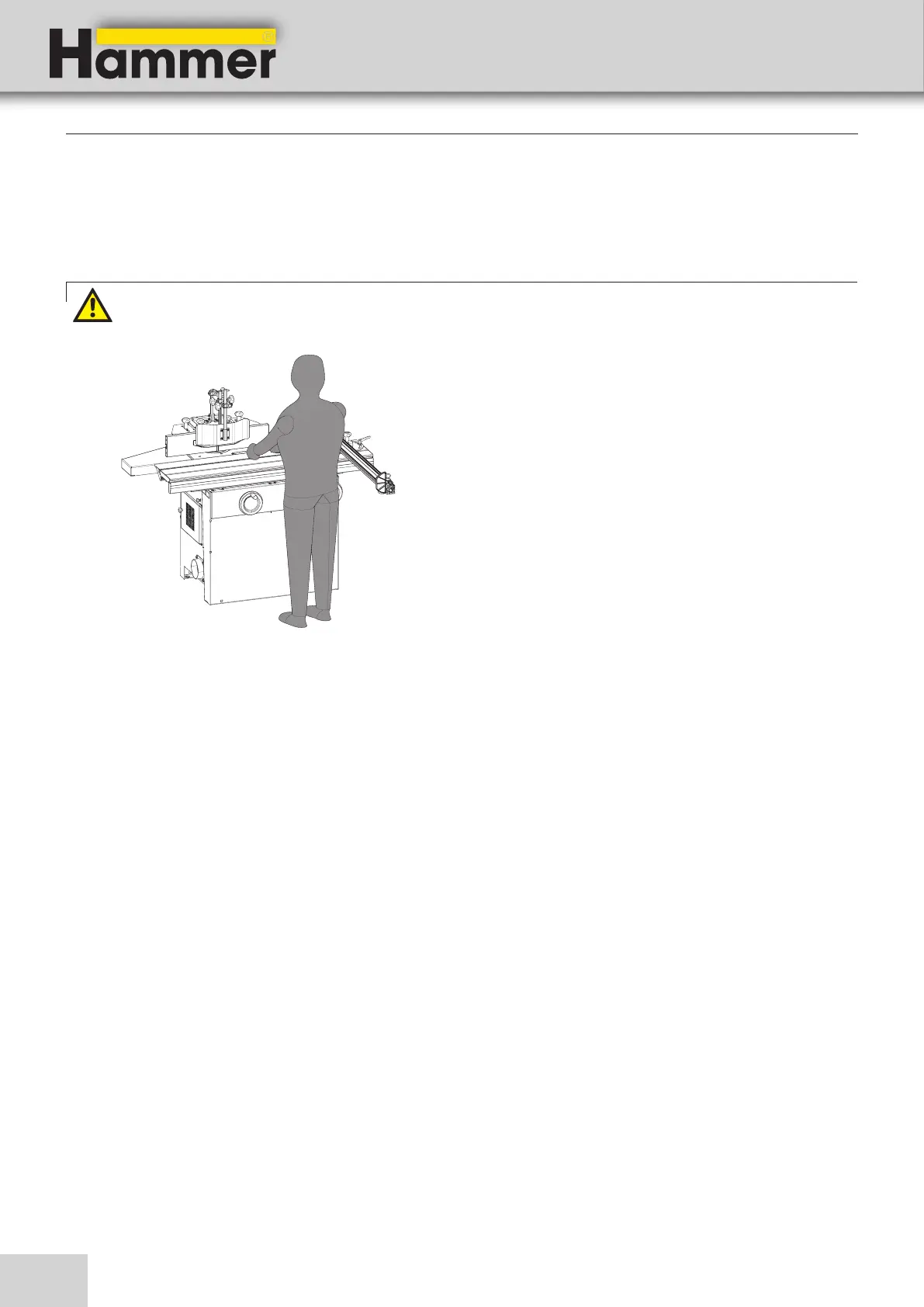

• Risk of injury due to ejected workpieces and workpi-

ece parts (e.g. cutting tools, branches, trimmings).

• Always work from right to left in front of the machi-

ne.

• Exception: For special operations (e.g. curve moul-

ding with clockwise spindle moulder rotational direc-

tion), work from left to right.

11.3.2 Authorised working techniques

11.3.3 Prohibited working techniques

The following working techniques are allowed with the moulder unit:

• Profile and long side moulding (using the spindle moulder fence)

• Insert moulding (using the spindle moulder fence)

• Curved mouldings (using the Curve Shaping Device)

• Slotting, tenoning and panel-raising (using a slot and tenon guard)

• Using a high velocity spindle

• Using a power feeder

Generally prohibited using the spindle moulder unit are the following working techniques:

• All working techniques without the use of a spindle moulder fence, curve moulding fence or slotting cover

• Synchronous moulding (the rotational moulding direction corresponds to that of the feeding direction)

• Use of higher speed, and/or a larger diameter than appears in the speed diagram

• Slotting with circular saw blades

• Use of tools with larger tool bores by using drill sleeves

Warning! Risk of injury!

Danger from ejected tools or workpiece parts

11.3.1 Work stations

11.3 Working techniques

Fig. 11-4: Work stations/Work positions

Operation

Loading...

Loading...