4. The host sends a Move Medium command to the robotics.

5. The picker takes the cartridge from the tape drive and places it in its storage slot.

Unload scenario 2: Library controlled

1. The host sends an Unload command to the drive.

2. The drive rewinds and unthreads the tape. It then pauses with the cartridge at ready-to-eject

position.

3. The library sends an Unload command to eject the cartridge.

4. The drive ejects the tape to Eject Point.

5. The picker takes the cartridge from drive and places it in its storage slot.

Load/unload forces

The load force varies according to the speed at which the cartridge is inserted into the drive. The

peak load force occurs when the cartridge begins to accelerate the drive carrier and only lasts for a

short time. Iin any automation environment, it is recommended that the cartridge is inserted into the

drive with a speed of between 25 mm/s to 55 mm/s. Going slower than this raises the possibility

that the Autoload may not trigger (half-height drives only) and going much faster increases the risk

of damaging the load mechanism.

The unload force is 5.8N maximum; this is the force that an external mechanism must exert to remove

a fully ejected cartridge from the drive.

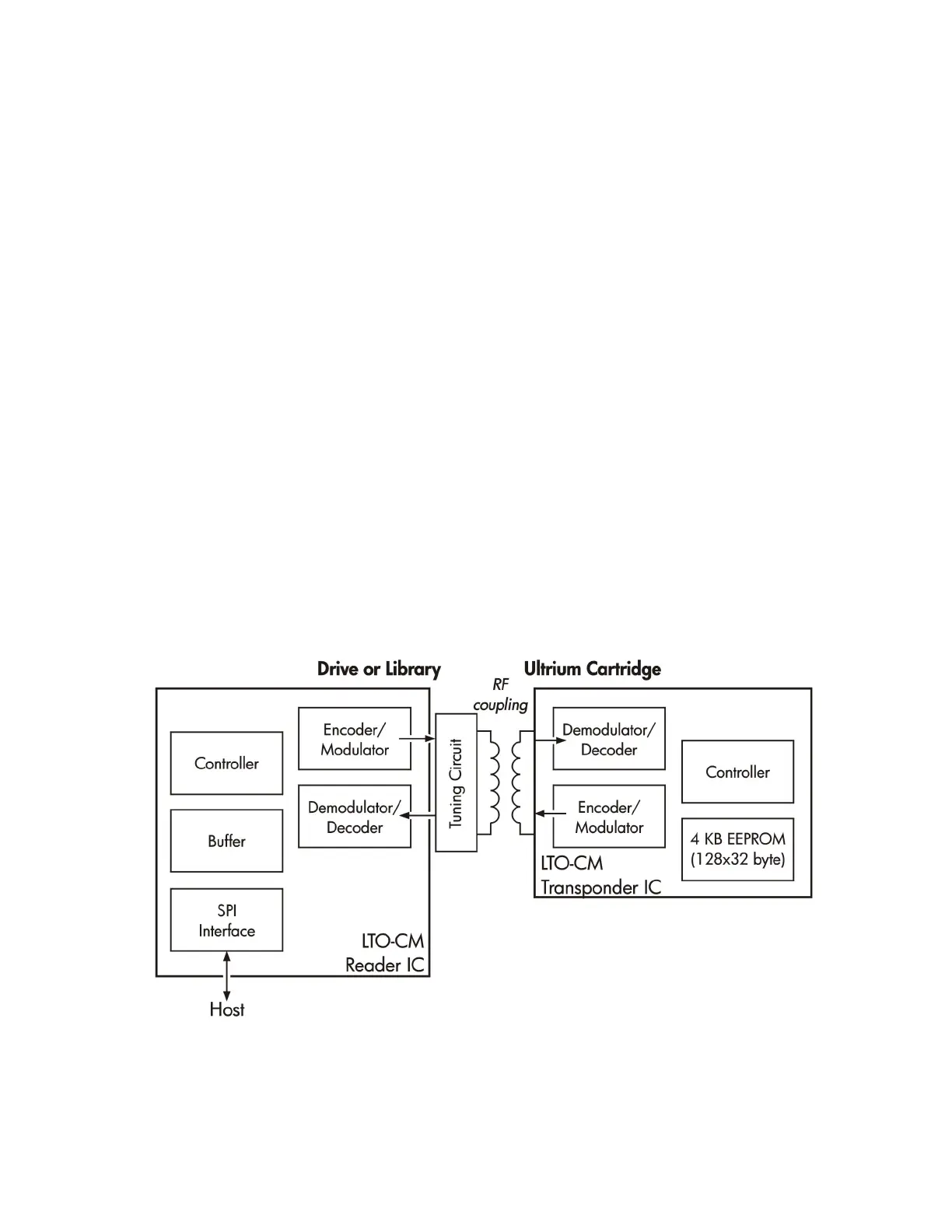

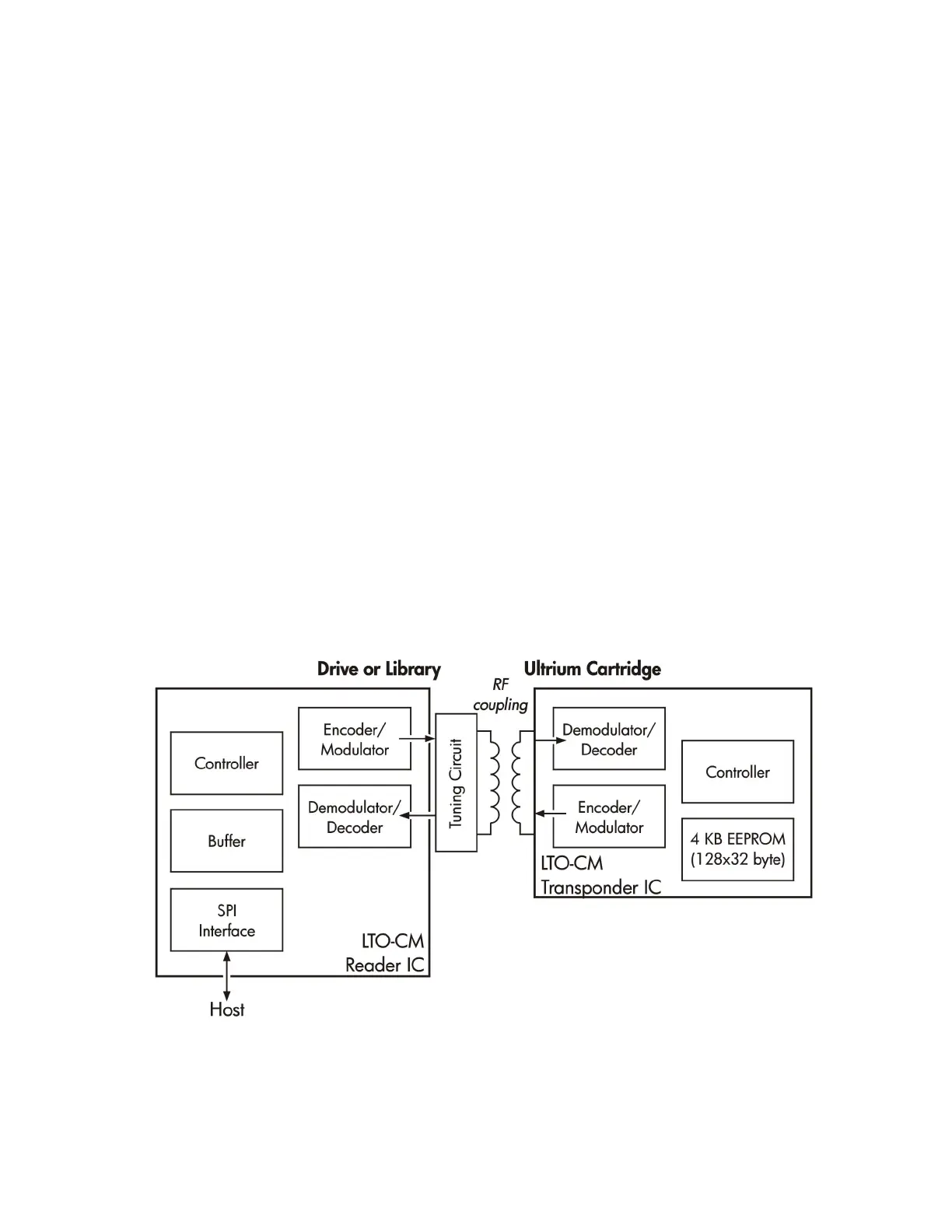

Using Cartridge Memory (LTO-CM) in libraries

Cartridge memory offers possibilities for use in libraries as an adjunct to or replacement for barcodes.

The following diagram shows the architecture required.

Volume 1: hardware integration 77

Loading...

Loading...