Chapter 8 Troubleshooting and Maintenance Shenzhen Hpmont Technology Co., Ltd.

92 HD5L-PLUS Series User Manual V1.0

Periodical Maintenance

Customer should check HD5L-PLUS in every 3 to 6 months according to the actual environment so as

to avoid hidden problems and make sure HD5L-PLUS runs well for a long time.

General inspection:

• Check whether the screws of control terminals are loose. If so, tighten them with a screw driver;

• Check whether the power terminals are properly connected; Whether the copper bar and cables are

overheated;

• Check whether the power cables and control cables are damaged, check especially for any wear on

the cable tube;

• The insulation wrapping tapes of the power cables and control cables are not peeled off or broken;

• Clean the dust on PCBs and air ducts with a vacuum cleaner.

Note:

1. Dielectric strength test of the controller has already been conducted in the factory. Do not do the test

again. Otherwise, the controller might be damaged.

2. If insulation test to the motor is necessary, it should be done after the input terminals U/V/W of motor

have been detached from HD5L-PLUS. Otherwise, HD5L-PLUS will be damaged.

3. For controllers that have been stored for a long time, they must be powered up every 2 years. When

supplying AC power to the controller, use a voltage regulator to gradually raise the input voltage to rated

input voltage at least 5 hours.

Replacing Damaged Parts

The components that are easily damaged: Cooling fan and electrolytic capacitors of filters.

Their lifetime depends largely on their application environment and preservation. Users can decide the

time when the components should be replaced according to their service time.

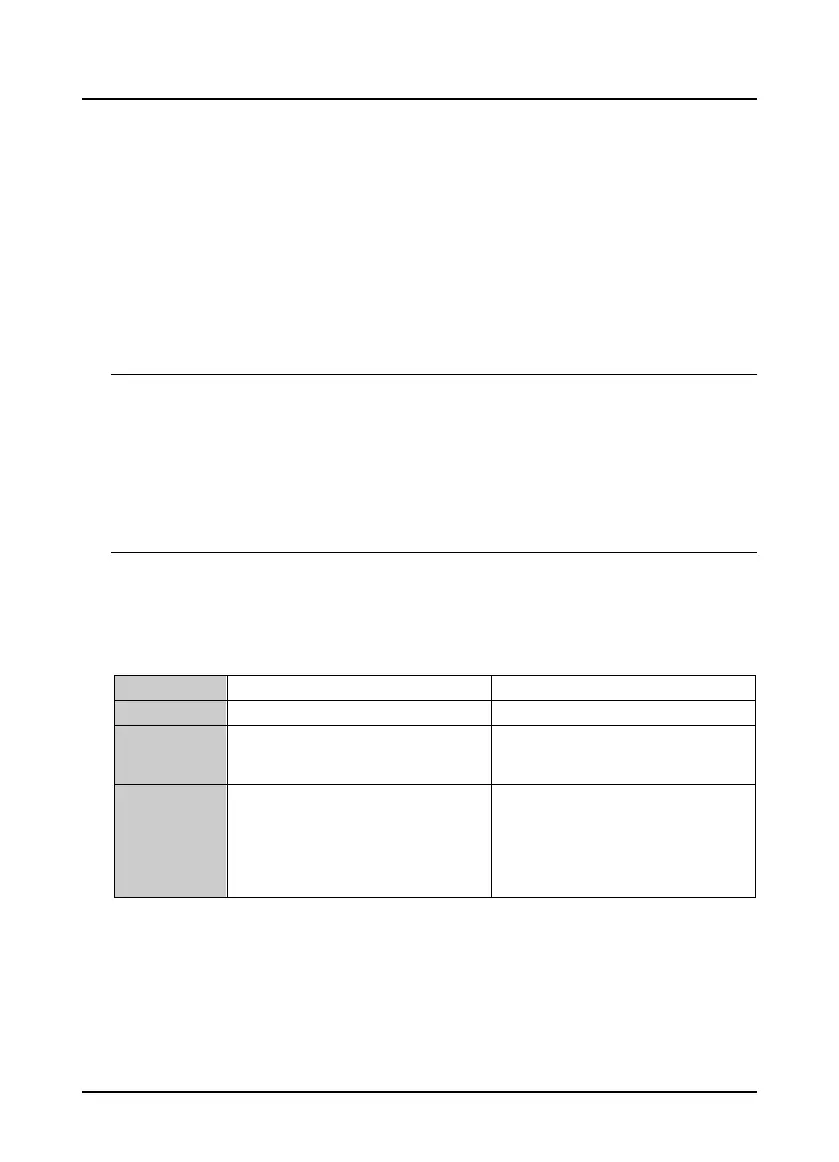

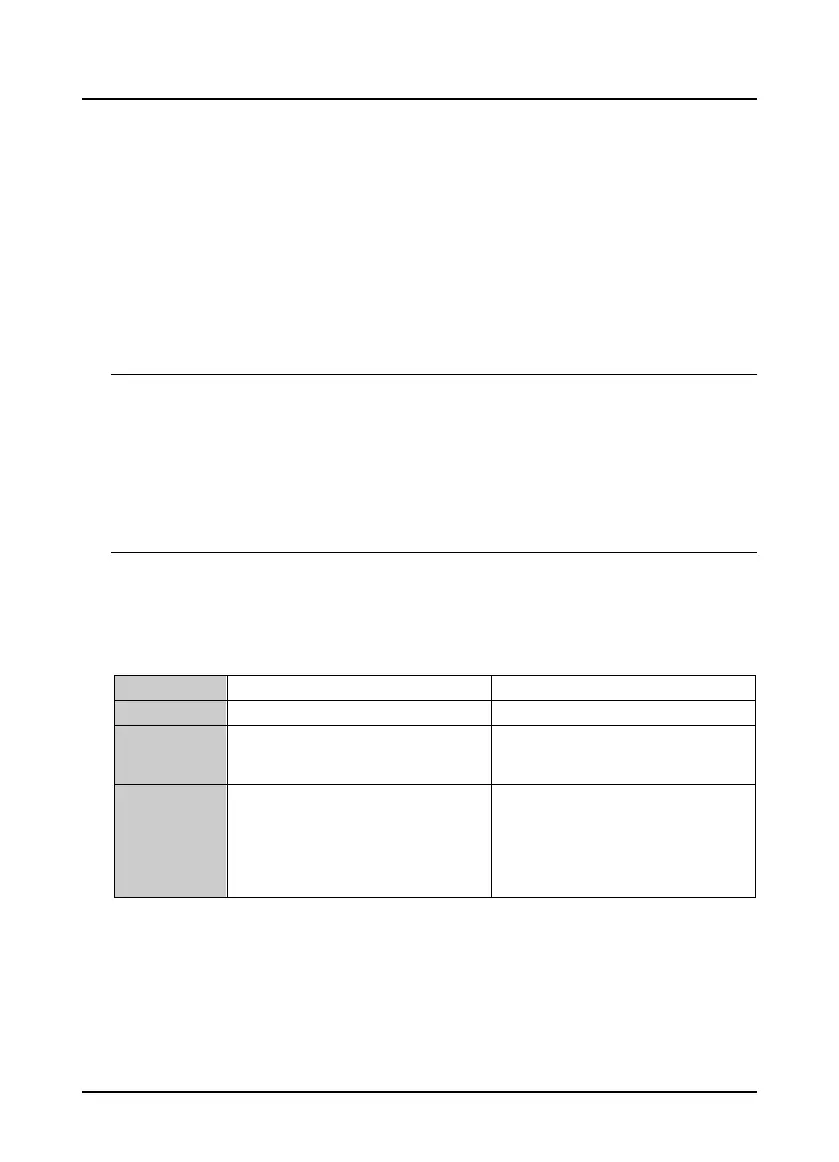

Easily Damaged Cooling fan Electrolytic capacitors

Life 60,000 hours 50,000 hours

Possible Cause of

Damages

Wear of the bearing, aging of the fan vanes

High ambient temperature, aging of

electrolyte and large pulse current induced by

rapid changing loads

Criteria

After the controller is switched off, check if the

abnormal conditions such as crack existing on

fan vanes and other parts. When the controller

is switched on, check if controller running is

normal, and check if there is any abnormal

oscillation

Check if frequent overcurrent or overvoltage

failures occur during controller start-up with

load. Check if there is any leakage of liquids.

Check if the safety valve protrudes. Measure

the static capacitance and insulation

resistance

Unwanted Controller Recycling

When disposing HD5L-PLUS, pay attention to the following factors:

• The capacitors may explode if they are burnt.

• Poisonous gas may be generated when the plastic parts like front covers are burnt.

• Disposing method: Dispose unwanted controllers as industrial waste.

Loading...

Loading...