Chapter 6 Function Introduction Shenzhen Hpmont Technology Co., Ltd.

56 HD5L-PLUS Series User Manual V1.0

Ref. Code

Function Description Setting Range [Default]

Defines the percentage of the corresponding rated load when the digital weighing signal terminal input is

valid.

For example: If DI weighing signal 1 is enabled, it indicates the present load = the rated load × F06.08.

• If multiple DI terminals are valid at the same time, the one with the largest terminal number is valid.

No weighing current coefficient

F06.15 No weighing speed-loop KP 1 - 9999 [2000]

No weighing speed-loop KI

F06.14 - F06.16 are used to adjust the effect of no weighing auto-compensation (F06.00 = 4).

• The system response can be expedited through increasing F06.14 - F06.16, but system oscillation and

overshoot may occur if the value of F06.14 - F06.16 is too high.

• Generally, it can smoothly start elevator via adjusting F06.14 when debugging.

• Increase F06.14 to avoid sliding vehicle at starting moment; Decrease F06.17 to avoid shake at starting

moment.

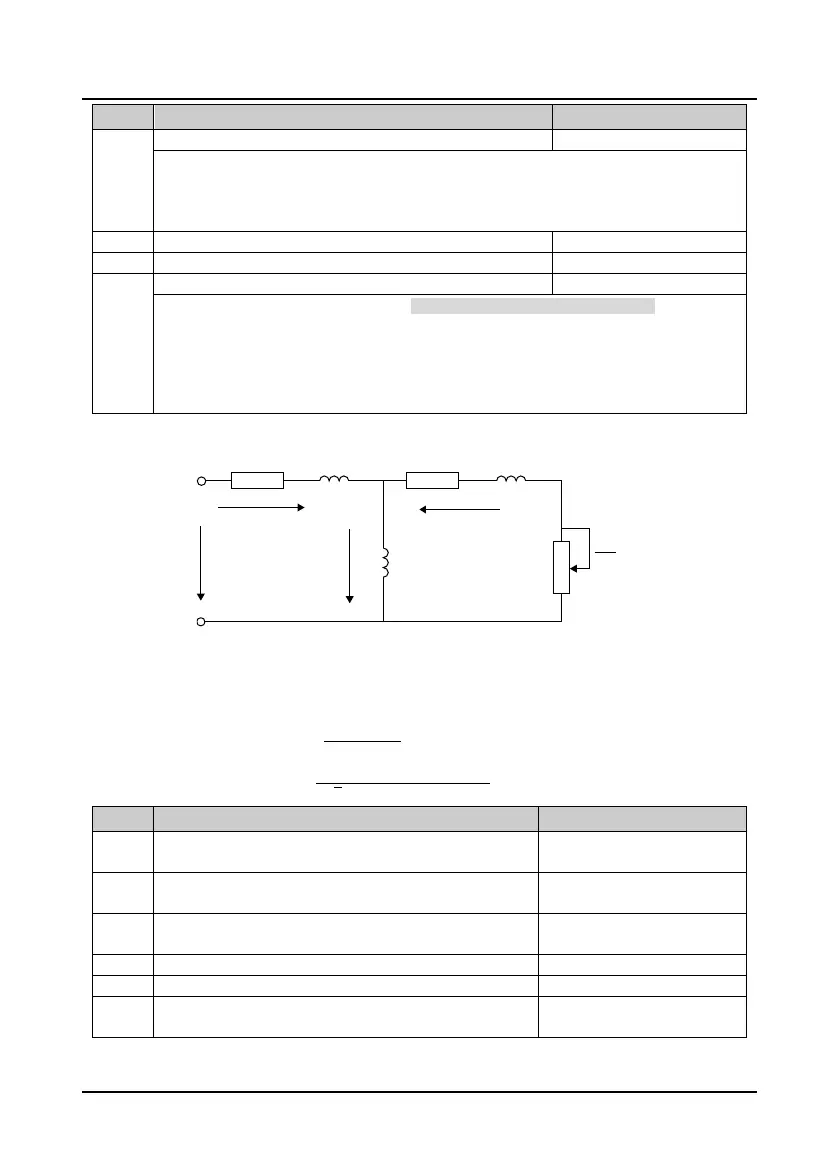

6.2.8 F07: Asyn. Motor Parameters

The relationship between rated torque current, excitation current and rated current of motor:

Rated torque current = F07.05 × F07.02

Excitation current F07.11 =

�

1 − F07.05

2

× F07.02

Mutual inductance F07.10 =

F07.01

2

√

3

π × F07.03 × F07.11

− F07.09

Ref. Code Function Description Setting Range [Default]

F07.00 Rated power of Asyn. motor 0.2 - 500.0kW

F07.01 Rated voltage of Asyn. motor 0V - Controller rated voltage

[Depend on HD5L-PLUS]

F07.02 Rated current of Asyn. motor 0.0 - 999.9A

F07.03 Rated frequency of Asyn. motor 1.00 - 100.00 [50.00Hz]

F07.05 Power factor of Asyn. motor 0.001 - 1.000

[Depend on HD5L-PLUS]

R

1 = F

0

7.

07

S

ta

to

r

re

si

st

an

c

e

R2 = F07.08 Rot

or r

esist

anc

e

Io = F07.11

Excitation current

R1 R2LI

I1 I2

S

1-S

R2

L

I

Lm

LI =F07.09 Leakageinductan

ce

Lm =F07.10 M

utual inductance

S =Slip ratio

U1

Io

Loading...

Loading...