______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 41/98

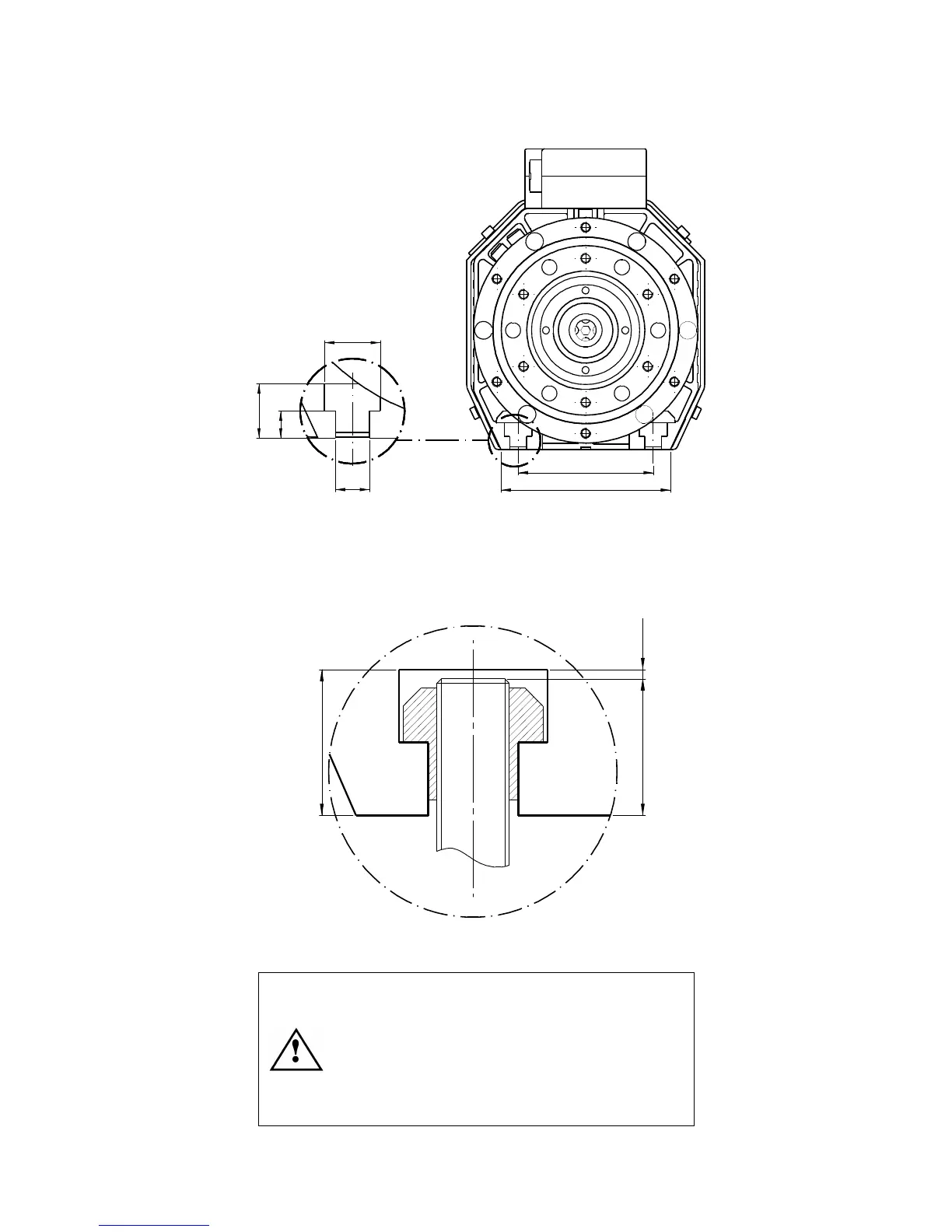

9.3.3 Mechanical fixing of the electro-spindle

80

100,5

10

8

16,5

Figure 9.2 T slots for anchoring the electro-spindle

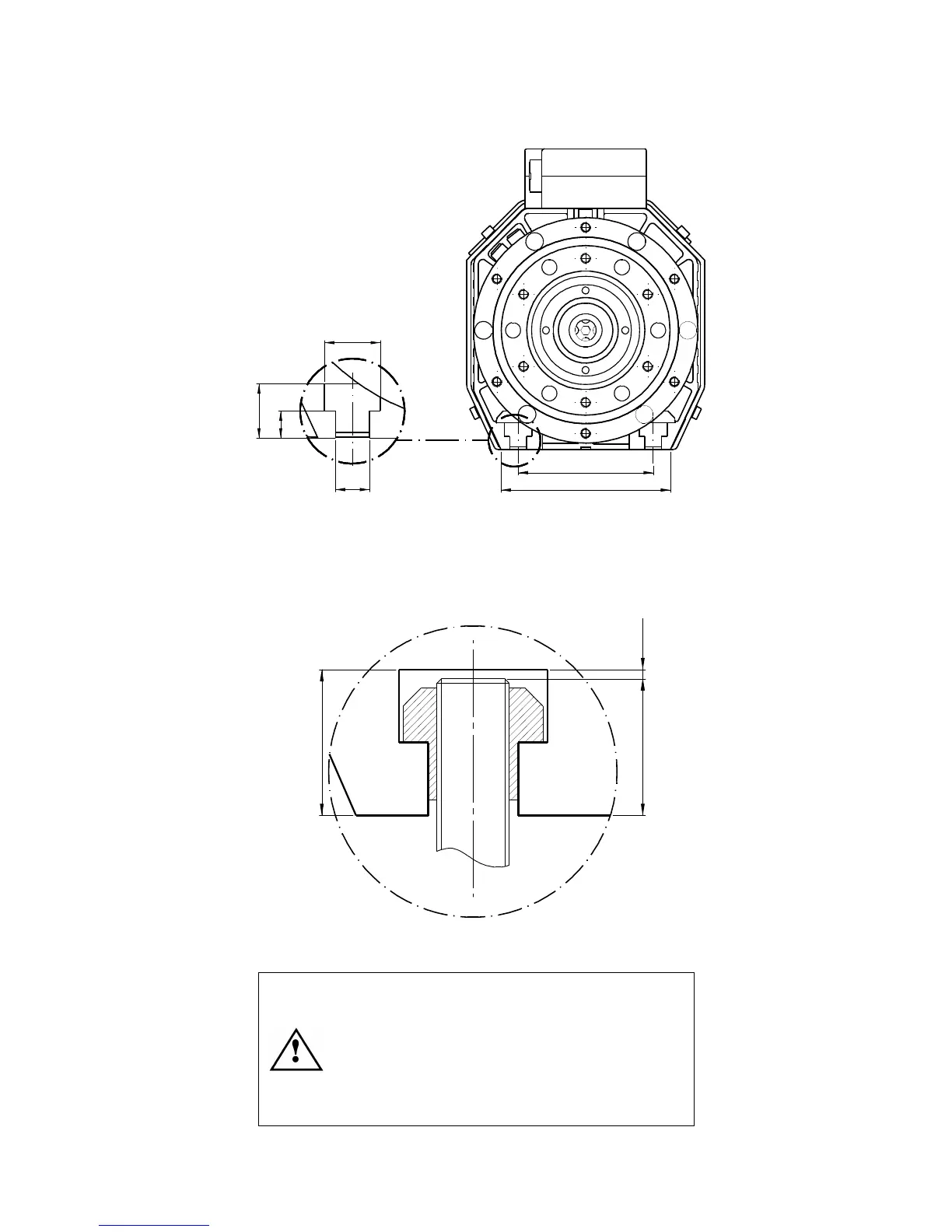

Fix the electro-spindle to the carriage or spindle mounting using M8 bolts and nuts fitted in the T

slots and tightened to a torque of 20 Nm. Maximum permitted protrusion of the fixing bolts is 15

mm, as shown in Figure 9.3. Greater protrusion can deform the electro-spindle body and lead to

incorrect fixing, reduced machining precision and reduced machining safety.

(16)

15 MAX 1 MIN

Figure 9.3 Maximum permitted protrusion of bolts in T slots

Maximum protrusion of bolt: 15 mm.

Leave a clearance of at least 1 mm.

Excessive protrusion can deform the

electro-spindle body and reduce machining

precision and safety.

Loading...

Loading...