______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 91/98

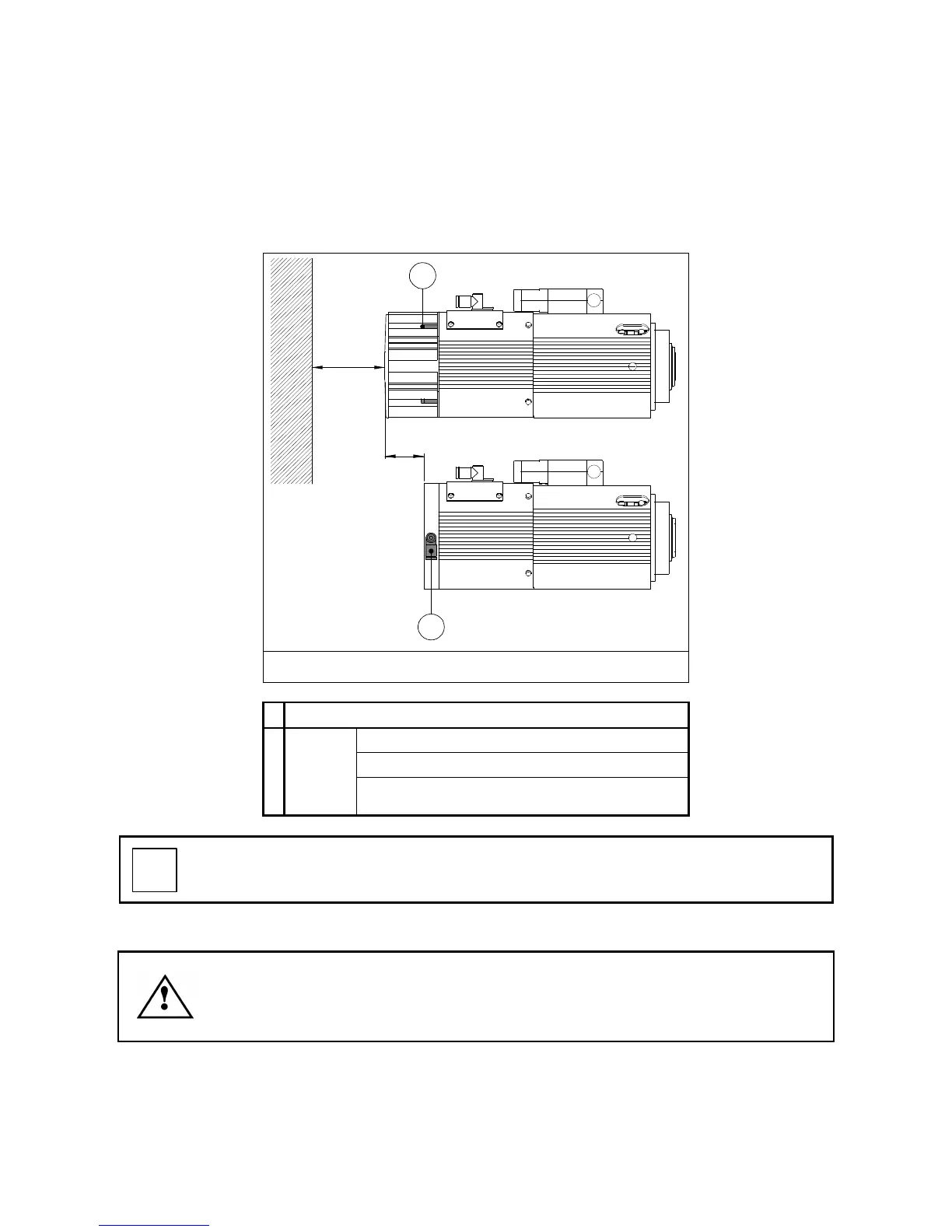

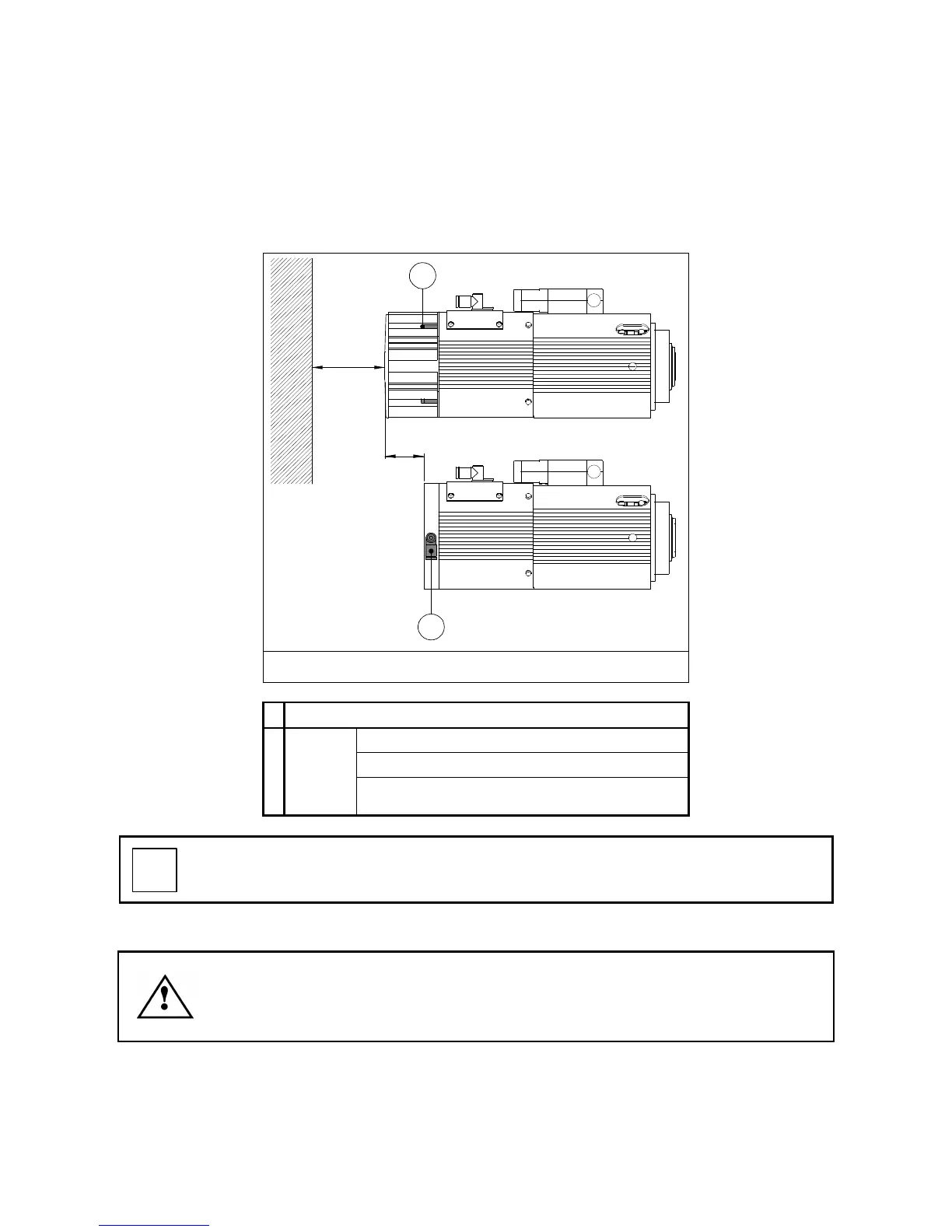

13.4 FORCED AIR COOLING

The electro-spindle can be cooled by compressed air instead of by the cooling fan.

Compressed air is delivered to a distribution flange, pre-fitted by HSD or retro-fitted as a kit.

This cooling solution reduces the overall length of the electro-spindle by 5 cm and dispenses with

the need to maintain a gap (10 cm) behind the fan. Compressed air cooling therefore reduces the

electro-spindle's overall space requirement by 15 cm (Figure 13.5).

A

50

100

B

Figure 13.5

A

Four cooling fan fixing screws

External hose Ø: 8 mm

Pressure: 6 / 7 bar – 85 / 100 PSI

B

Cooling

air inlet

Consumption: 4 cfm referred to 1 Atm, 68°F

(7000 normal litres/hour)

The stated values for air consumption and inlet pressure are for the S1 duty type

described in the tables in chapter § 7. If the unit is used with lighter duty types, the user

can evaluate whether to reduce air consumption by lowering the inlet pressure.

13.4.1 Installing the forced air cooling kit

BEFORE STARTING ANY WORK ON THE ELECTRO-SPINDLE, READ AND

FOLLOW ALL THE SAFETY PRECAUTIONS AND MAINTENANCE SAFETY

WARNINGS.

SEE IN PARTICULAR CHAPTER § 5 AND PAGES 66 AND 71 OF CHAPTER § 12.

1. Remove the fixing screws and pull the fan unit off the electro-spindle (see section 12.2.1 ).

2. Disconnect the cooling fan's electrical connector and fit the bridge connector provided.

3. Fit the air distribution flange in the place of the cooling fan unit and secure it with the four

screws removed from the fan unit.

4. Connect the compressed air supply to the quick-fit union (B) on the air distribution flange.

Loading...

Loading...