______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 90/98

• Apply some Loctite 243 or equivalent medium strength

thread locking compound to the threads of the sensor.

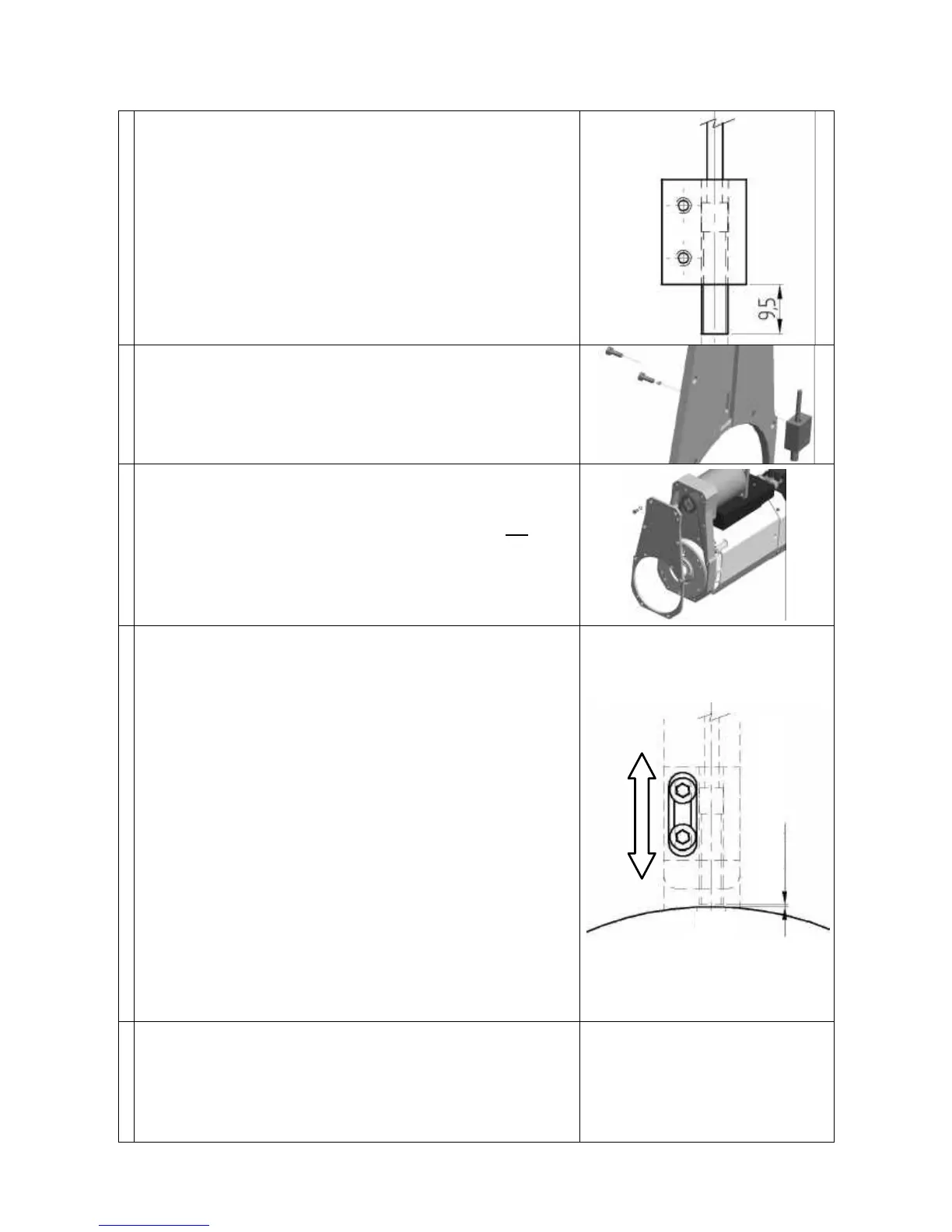

• Screw the sensor into the side of the sensor block with

the largest hole.

• Screw the sensor in until you achieve the protrusion

shown in the figure on the right.

• Wait for the thread locking compound to set in

compliance with the manufacturer's instructions.

• Fit the assembled sensor + sensor block to the cover

(figure on the right), but leave the screws loose enough

for the sensor block to move.

• Apply silicon sealant to the sensor cable hole.

• Check that the C axis unit is still in a position other than

the zero position, i.e. that the drive pin hole is not in the

position shown in Figure 13.4. Turn the C axis unit if

necessary.

• Fit the cover back on the body of the C axis unit. Fit and

tighten all the fixing screws (figure on the right).

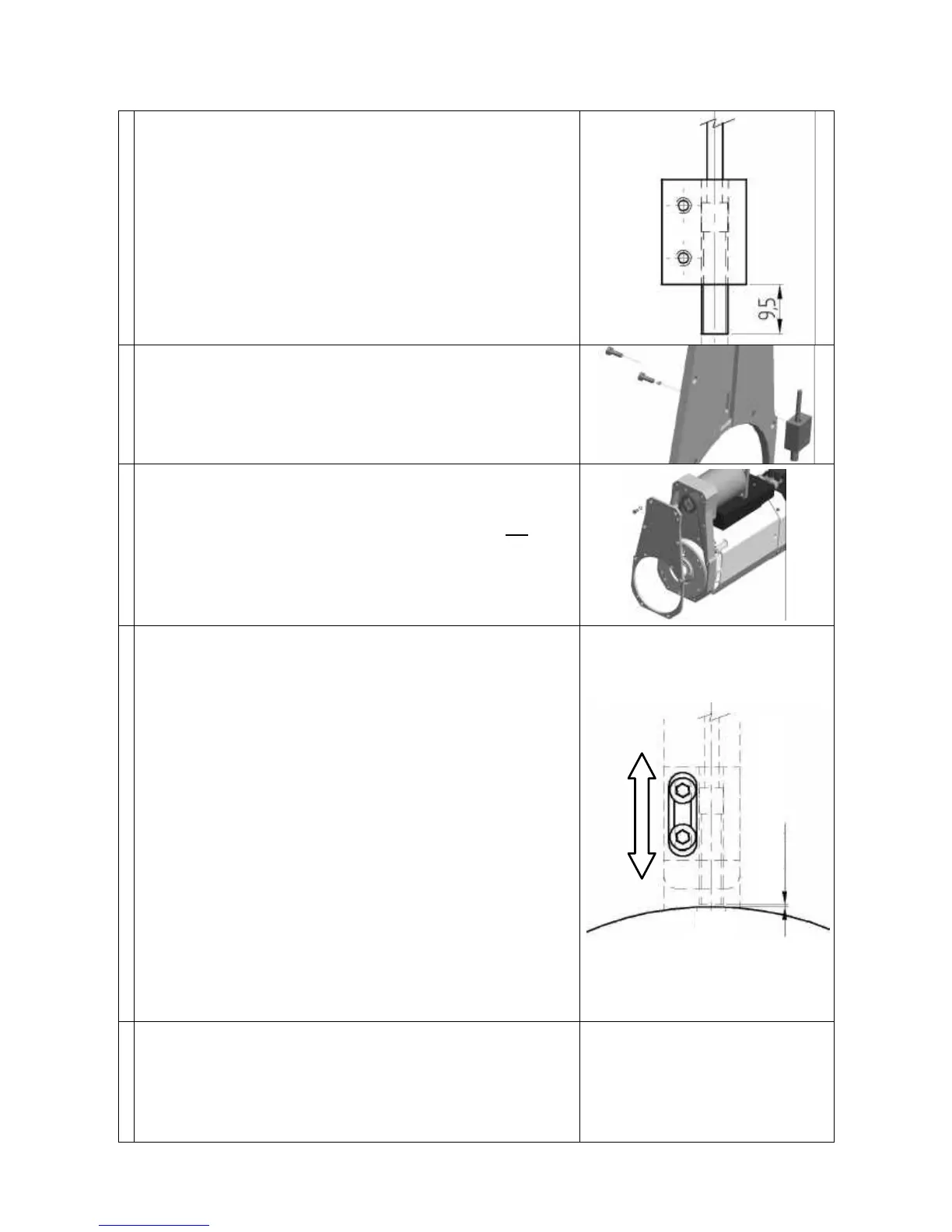

• Adjust the sensor read distance using either

“PROCEDURE_A” or “PROCEDURE_B”:

PROCEDURE A

• Place a shim of 0.2 mm between the pulley and the

sensor.

• Push the sensor against the pulley and into firm contact

with the shim.

• Tighten the two sensor block fixing screws.

• Remove the shim.

PROCEDURE B

• Push the sensor against the pulley and check that the

sensor contacts are open.

• Slowly slide the sensor away from the pulley until the

contacts close.

• Slowly slide the sensor towards the pulley again until the

contacts just open.

• Tighten the two sensor block fixing screws.

• Re-connect the electro-spindle's electrical connections.

• Turn the C axis unit, and check that the contacts of

sensor SC remain closed at all positions other than zero

position (see Figure 13.4) when they must open.

• Check sensor functioning at as many axis positions as

practical.

Loading...

Loading...