______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 92/98

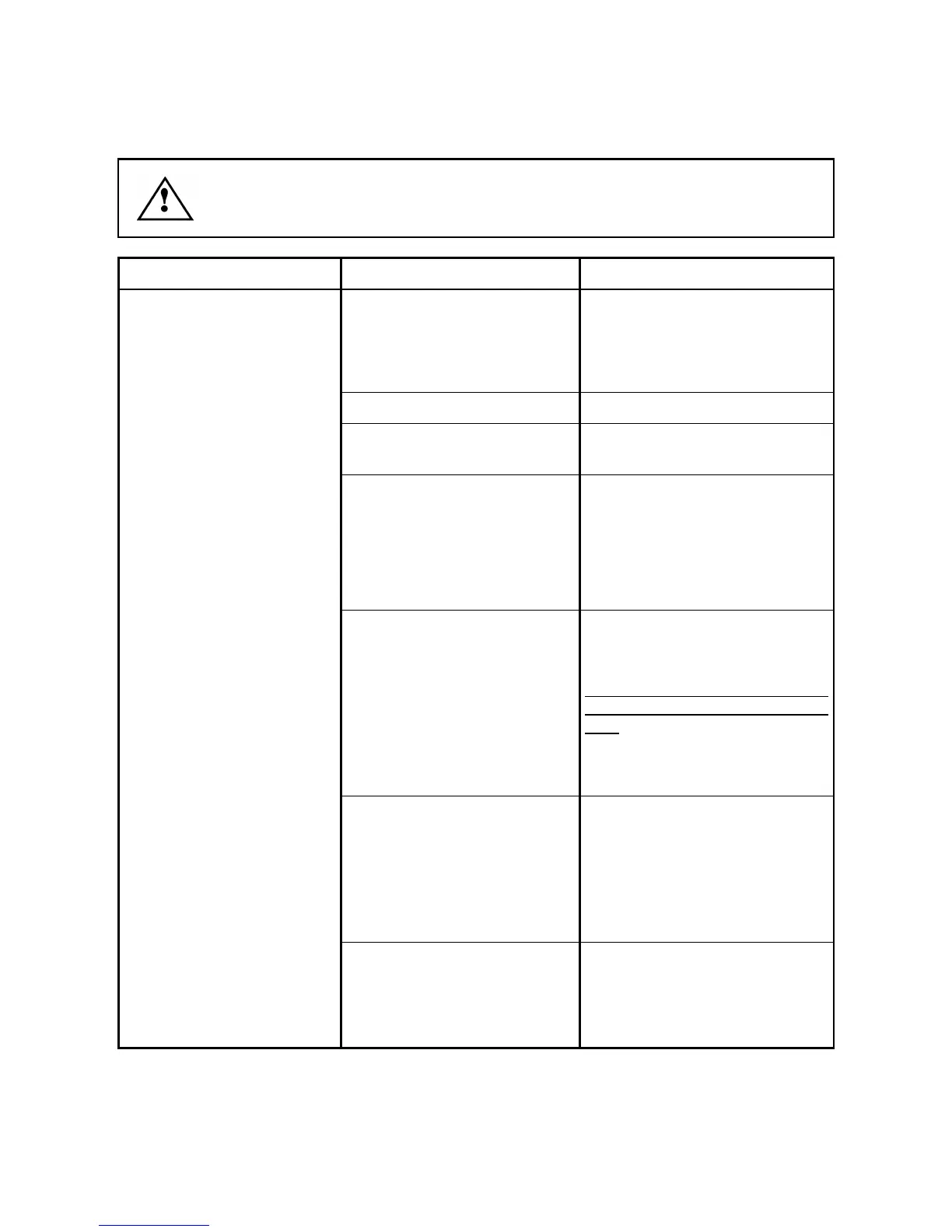

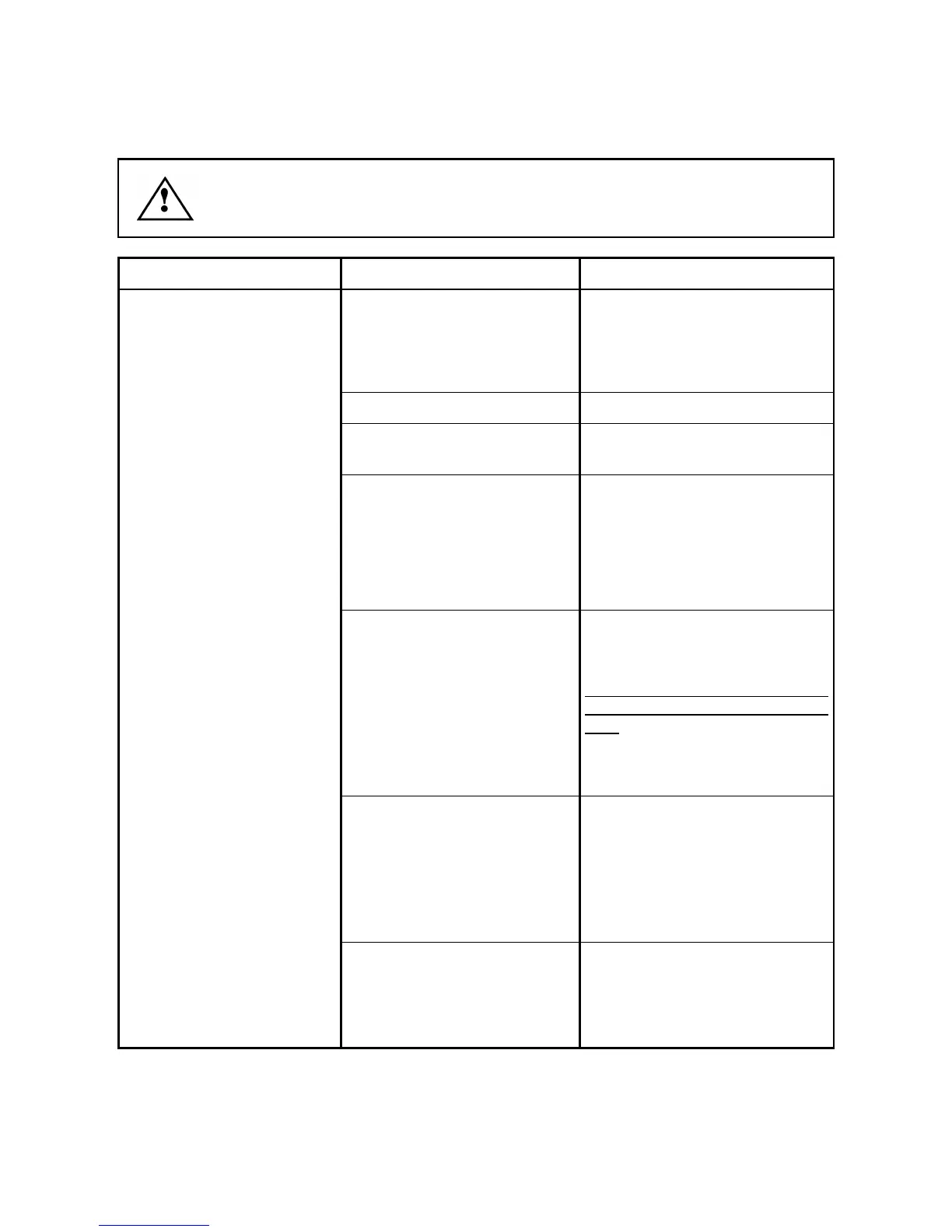

§ 14 TROUBLE SHOOTING

BEFORE STARTING ANY WORK ON THE ELECTRO-SPINDLE, READ AND

FOLLOW ALL THE SAFETY PRECAUTIONS AND MAINTENANCE SAFETY

WARNINGS.

PROBLEM PROBABLE CAUSE CORRECTIVE ACTION

There is no power

• Check the mains power

supply.

• Check all power terminals.

• Check all electrical cables and

connections for breaks.

No tool holder is fitted Fit a tool holder.

The tool holder not correctly

seated

See “The tool holder is not

locked” below.

The thermal switch has tripped

Wait for the electro-spindle to cool

down and the thermal switch will

automatically reset.

If the thermal switch trips

frequently, see “The electro-

spindle overheats” below.

The inverter switch has tripped

Consult the inverter's own manual

or contact the inverter

manufacturer.

On electro-spindles with

configurable power terminals

only: see section 9.6.6 and check

that the power terminals are

configured correctly for the mains

power rating.

Sensor S1 (ISO 30) or sensor

series <S1+S4> (HSK) is

disconnected or faulty

• Check the sensor connectors.

• Check the sensor cables for

breaks.

• Calibrate the sensors as

instructed in section 12.2.4 .

• Replace any faulty sensors as

instructed in section 12.2.4 .

The electro-spindle does

not turn

There is no electro-spindle

enabling signal

Consult the manuals or contact

the manufacturers of the

machine, numeric controller, and

inverter.

Loading...

Loading...