______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 38/98

§ 8 TRANSPORT AND MOVING

Lifting and moving electro-spindles can create situations of risk to persons nearby. Always follow

the instructions provided by HSD and always use suitable lifting equipment.

Installation and assembly work must be performed only by specialist technicians.

Always use great care in lifting and moving electro-spindles and their components. Avoid impacts

that can damage the body which could cause malfunctions.

IT IS THE RESPONSIBILITY OF THE CUSTOMER TO ENSURE THAT THE LIFTING EQUIPMENT,

CABLES, SLINGS AND CHAINS USED IS SUITABLE FOR THE PURPOSE IN TERMS OF

FUNCTIONING AND LOAD CAPACITY.

8.1 STORAGE

If the electro-spindle is to be stored for any length of time, make sure that it is protected against the

elements and in particular against damp, dust, and other forms of damage by the atmosphere or

storage environment.

Check on the general condition of the electro-spindle periodically to prevent deterioration. Turn the

spindle shaft by hand about once a month to keep the bearings free.

STORAGE TEMPERATURE: from –5°C (+23°F) to +55°C (+131°F)

NON-CONDENSING RELATIVE HUMIDITY: from 5% to 90%

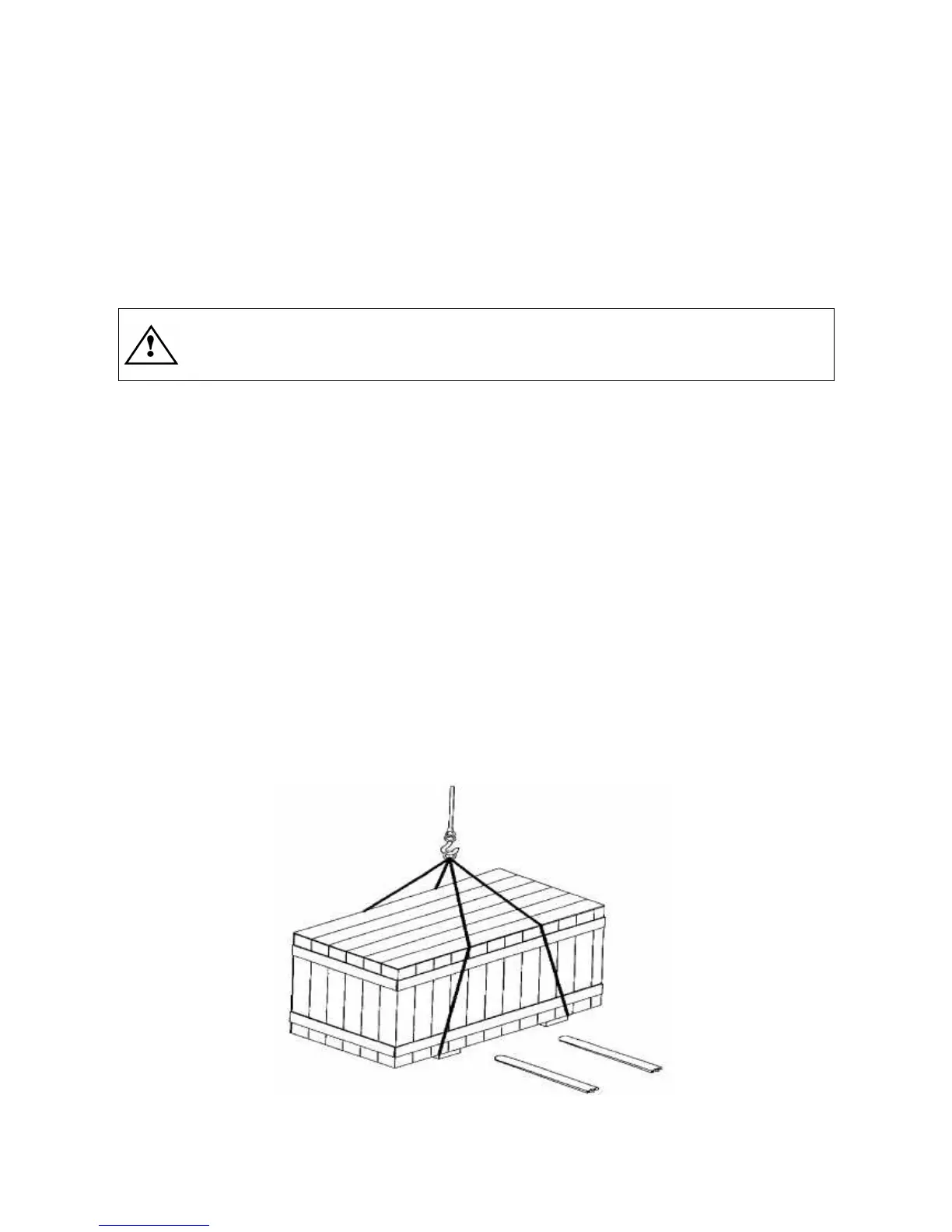

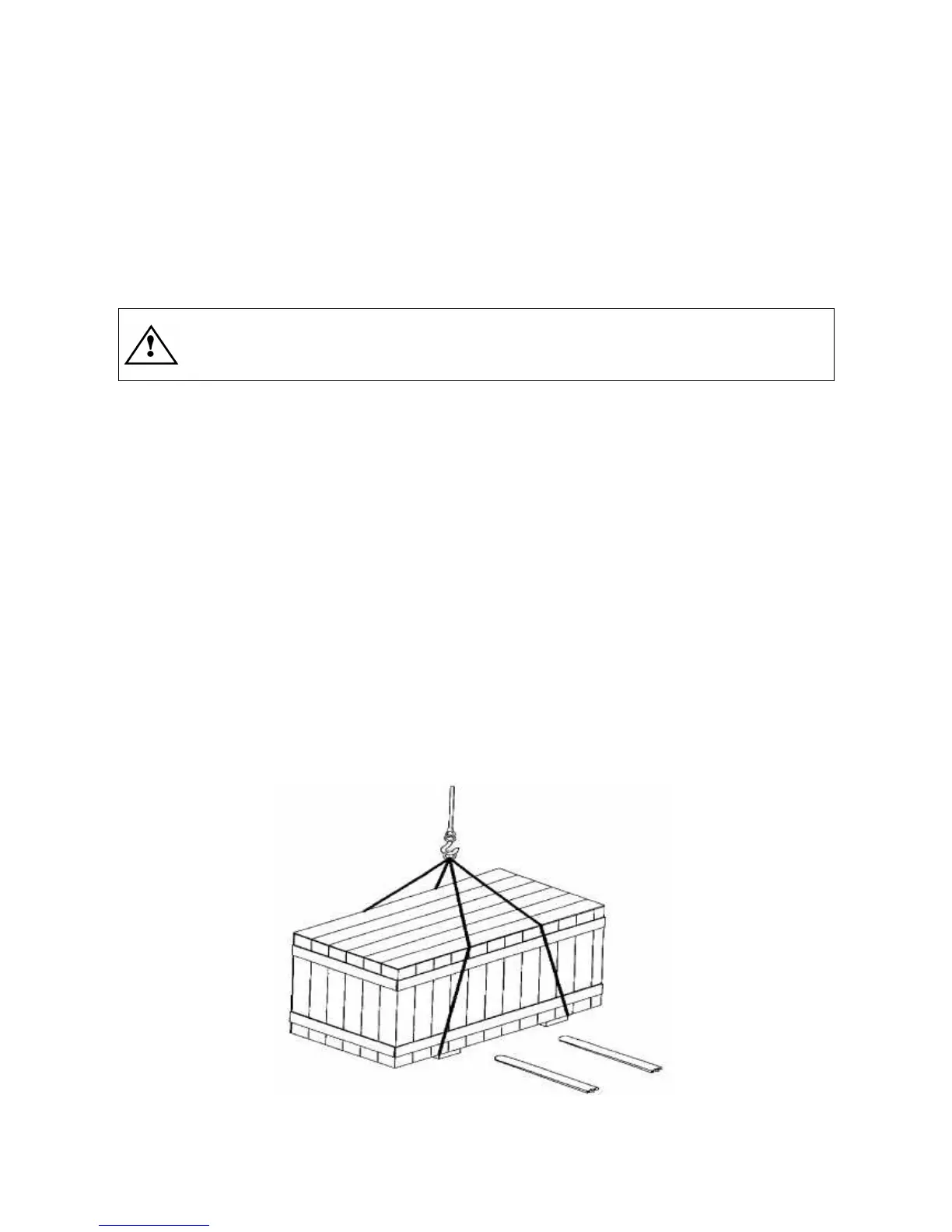

8.2 LIFTING THE ELECTRO-SPINDLE IN ITS CRATE

The electro-spindle is shipped in a wooden crate packed with expanded polystyrene foam. The

electro-spindle itself is packed in a VCI plastic bag and is coated in protective grease to prevent

corrosion. Use a clean cloth to wipe the protective grease off the new electro-spindle.

(Note: The expanded polystyrene and the protective bag are plastics and must be disposed of as

such).

Figure 8.1 Example of how to lift the crate

Loading...

Loading...