______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 70/98

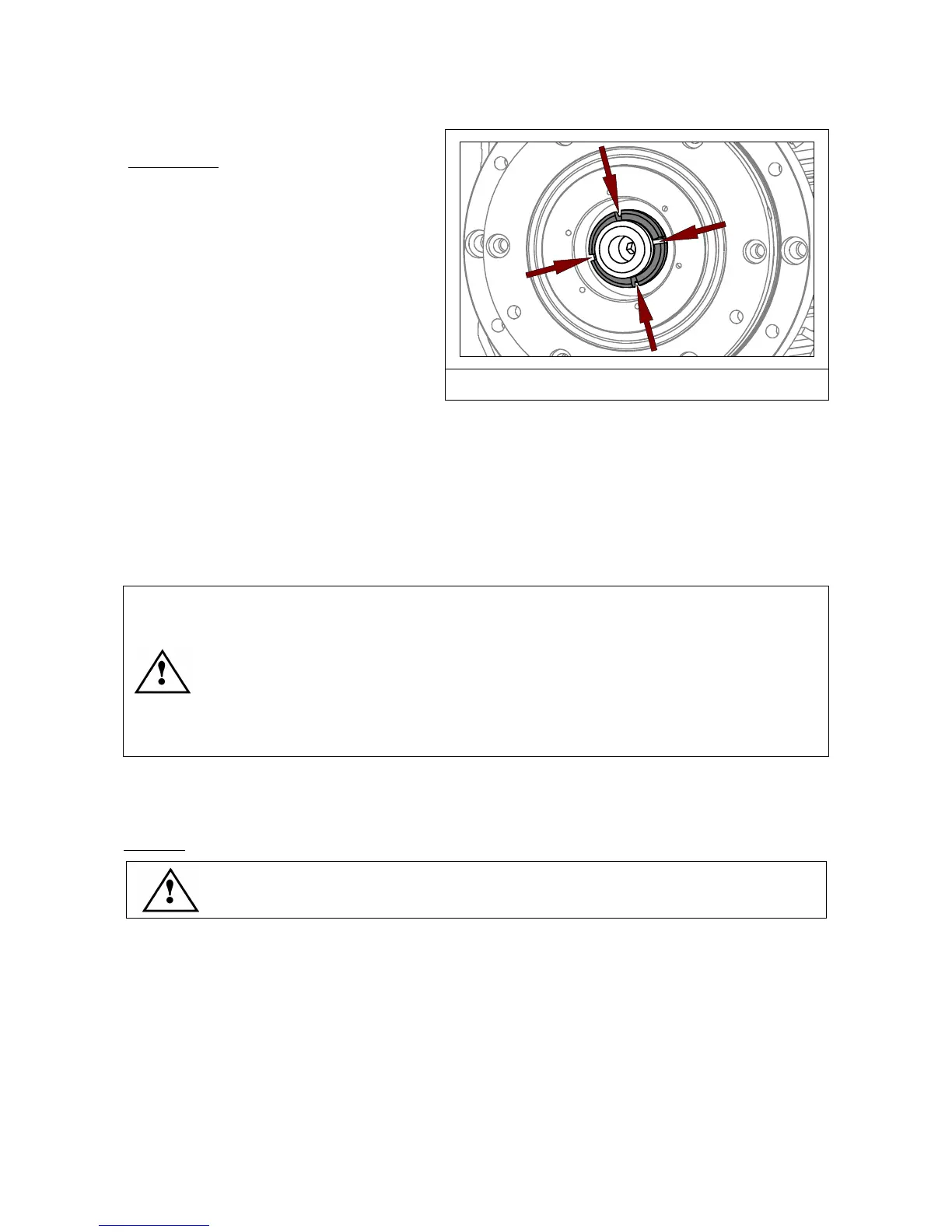

12.1.4 Lubricating HSK fingers

MONTHLY

To keep HSK type collets perfectly

efficient, grease them every month with:

METAFLUX-Fett-Paste Nr.70-8508

or:

METAFLUX-Moly-Spray Nr.70.82

Apply the grease into the gaps between

the collet sections as shown in Figure

12.6.

Figure 12.6 Monthly greasing of HSK fingers

TOO MUCH GREASE CAN CAUSE DAMAGE.

After you have applied the specified grease as shown in Figure 12.6, perform a number of tool

changes to distribute it evenly. Then remove the tool holder from the spindle shaft and wipe any

visible lumps of grease off with a clean cloth. Free standing grease can retain metal particles and

dirt from the machining, and foul the fingers, cone and faces. These parts must be kept as clean as

possible to ensure operator safety and machining precision and to reduce wear of the spindle and

tool holder cone.

ONLY USE THE GREASE LISTED ABOVE.

OTHER PRODUCTS ARE NOT COMPATIBLE WITH THE GREASE

INITIALLY APPLIED BY HSD.

IF INCOMPATIBLE GREASES ARE MIXED OR APPLIED TO THE SAME

FINGERS, THEY CAN REACT TO FORM SUBSTANCES THAT CAUSE

DAMAGE OR PREVENT CORRECT COLLET FUNCTIONING, WITH

SERIOUS CONSEQUENCES FOR OPERATOR SAFETY.

12.1.5 Bearings

NEVER

THE BEARINGS ARE LUBRICATED FOR LIFE AND DO NOT REQUIRE

GREASING.

Loading...

Loading...