______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 81/98

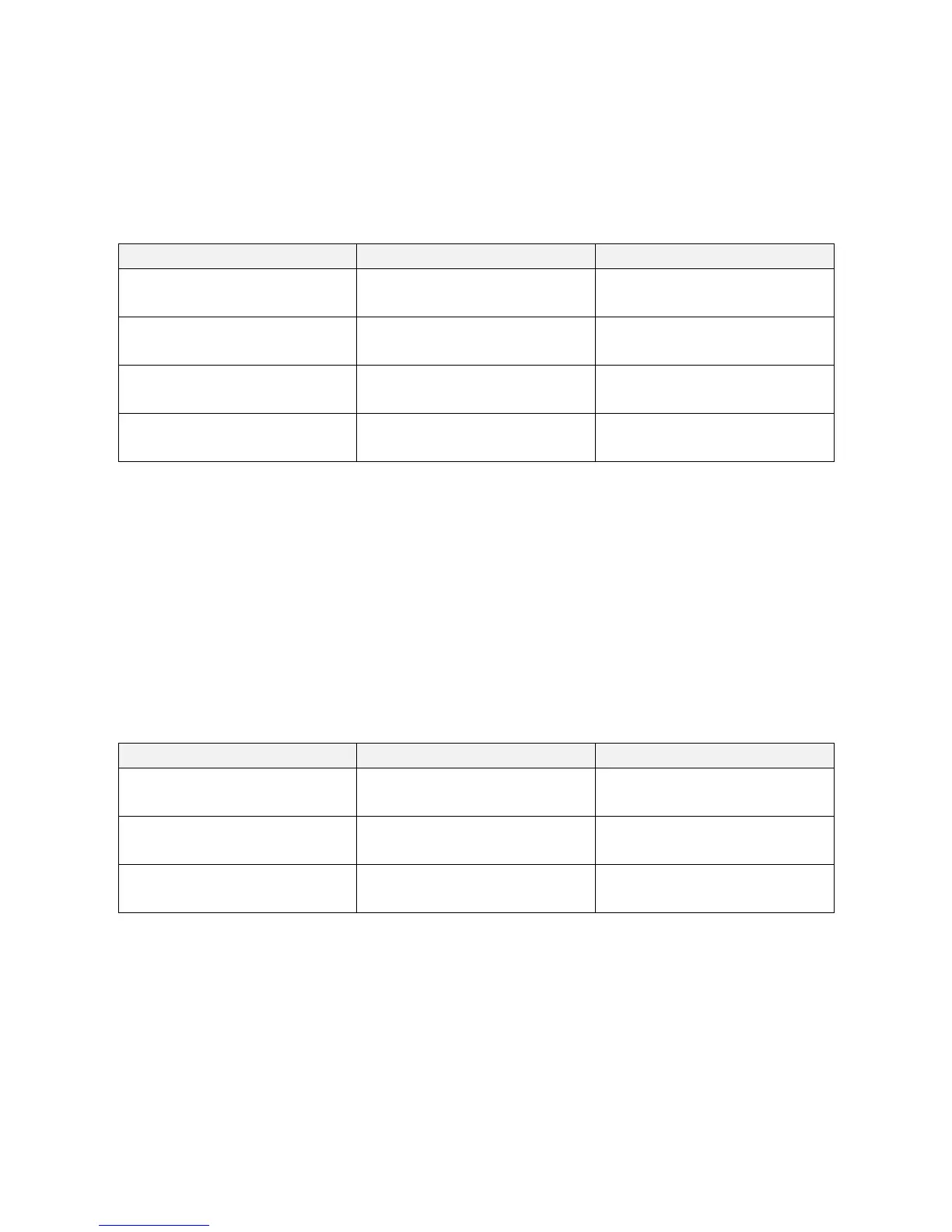

12.2.4.10.1 Procedure for S1

When you have replaced the sensor as instructed in section 12.2.4.6 , calibrate it as follows.

1. Use the 14.29 mm gauge and the 0.04 mm shim as shown in Figure 12.22 and Figure 12.23,

and check whether the output signal from sensor S1 corresponds to the following table.

CONDITION SHIM IN PLACE OUTPUT S1

Gauge locked

(tool holder locked)

YES

HIGH (+24V)

Gauge locked

(tool holder locked)

NO

LOW (0V)

No gauge

(no tool holder)

-

LOW (0V)

Collet open

(tool holder ejected)

-

LOW (0V)

2. Turn the spindle shaft by hand and check whether the conditions in the table are fulfilled

through 360° of a complete revolution.

3. If they are not, turn the sensor seat (4) until you obtain the output specified in the table. Hold

the sensor in this position and tighten the fixing screw (6).

4. Perform as many tests as possible using all available tool holders to verify the effectiveness of

the new sensor calibration.

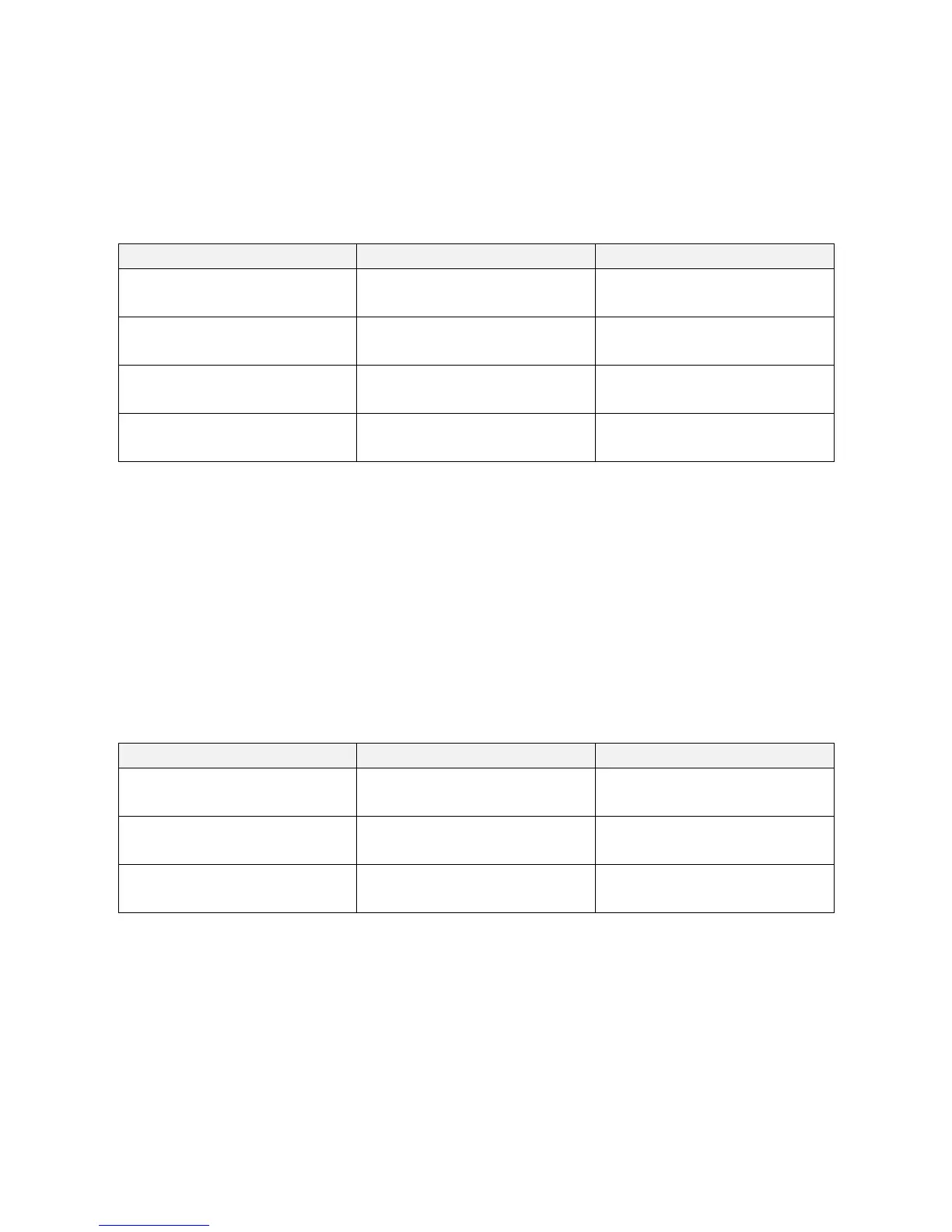

12.2.4.10.2 Procedure for S4

When you have replaced the sensor as instructed in section 12.2.4.6 , calibrate it as follows.

1. Use the 14.13 mm gauge and the 0.12 mm and 0.16 mm shims as shown in Figure 12.22 and

Figure 12.23, and check whether the output signal from sensor S4 corresponds to the following

table.

CONDITION SHIM IN PLACE OUTPUT S1

Gauge locked

(tool holder locked)

0.12 mm HIGH (+24V)

Gauge locked

(tool holder locked)

0.16 mm LOW (0V)

Collet open

(tool holder ejected)

- LOW (0V)

2. Turn the spindle shaft by hand and check whether the conditions in the table are fulfilled

through 360° of a complete revolution.

3. If they are not, turn the sensor seat (4) until you obtain the output specified in the table. Hold

the sensor in this position and tighten the fixing screw (6).

4. Perform as many tests as possible using all available tool holders to verify the effectiveness of

the new sensor calibration.

Loading...

Loading...