______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 67/98

12.1 SCHEDULED MAINTENANCE

The following maintenance schedule must be followed scrupulously to keep the electro-spindle in

peak condition.

The frequency has been calculated taking into account an 8-hour a day, 5-dayworking

week, in a normal working environment.

12.1.1 Checking the cleanliness of the tool holder cone and of the spindle

shaft tool housing

DAILY

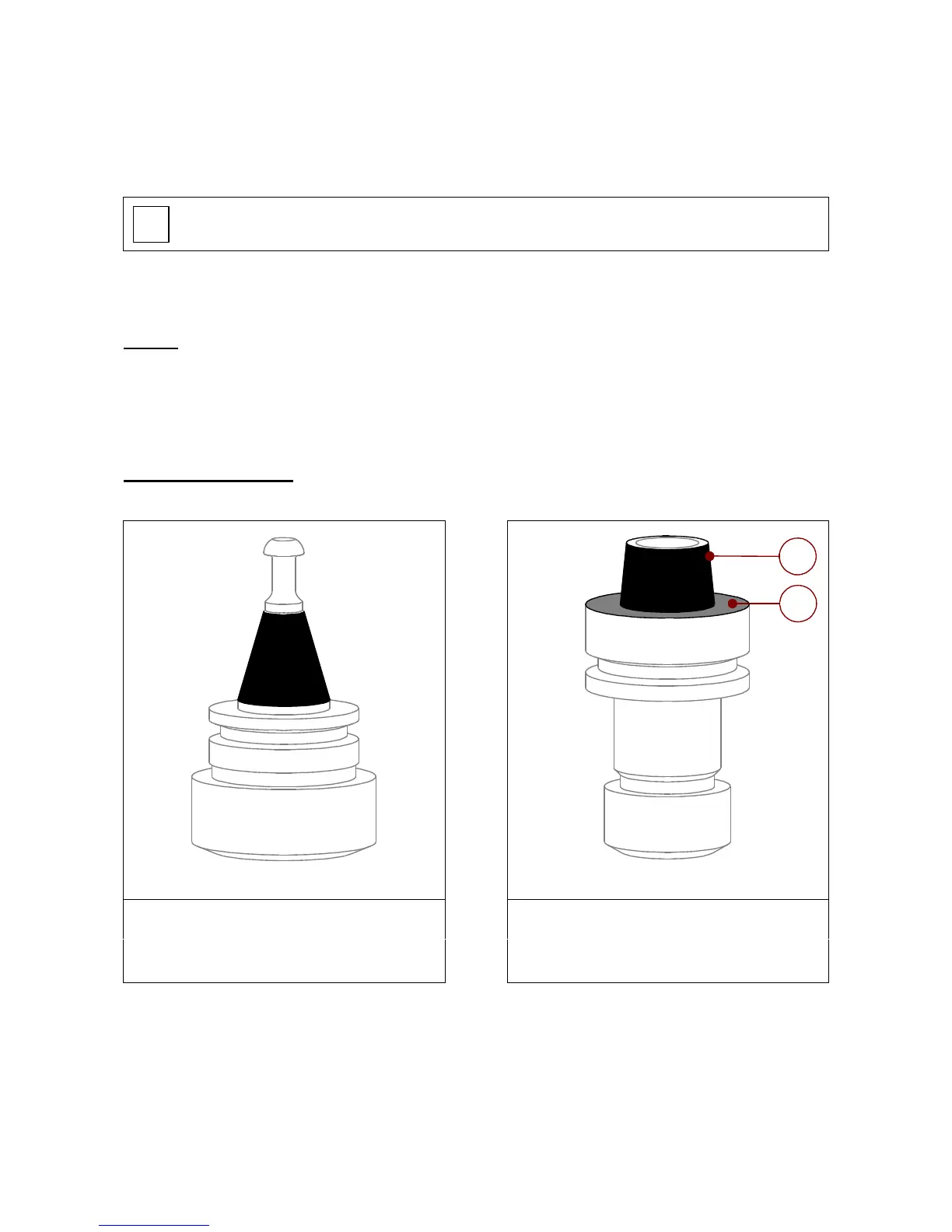

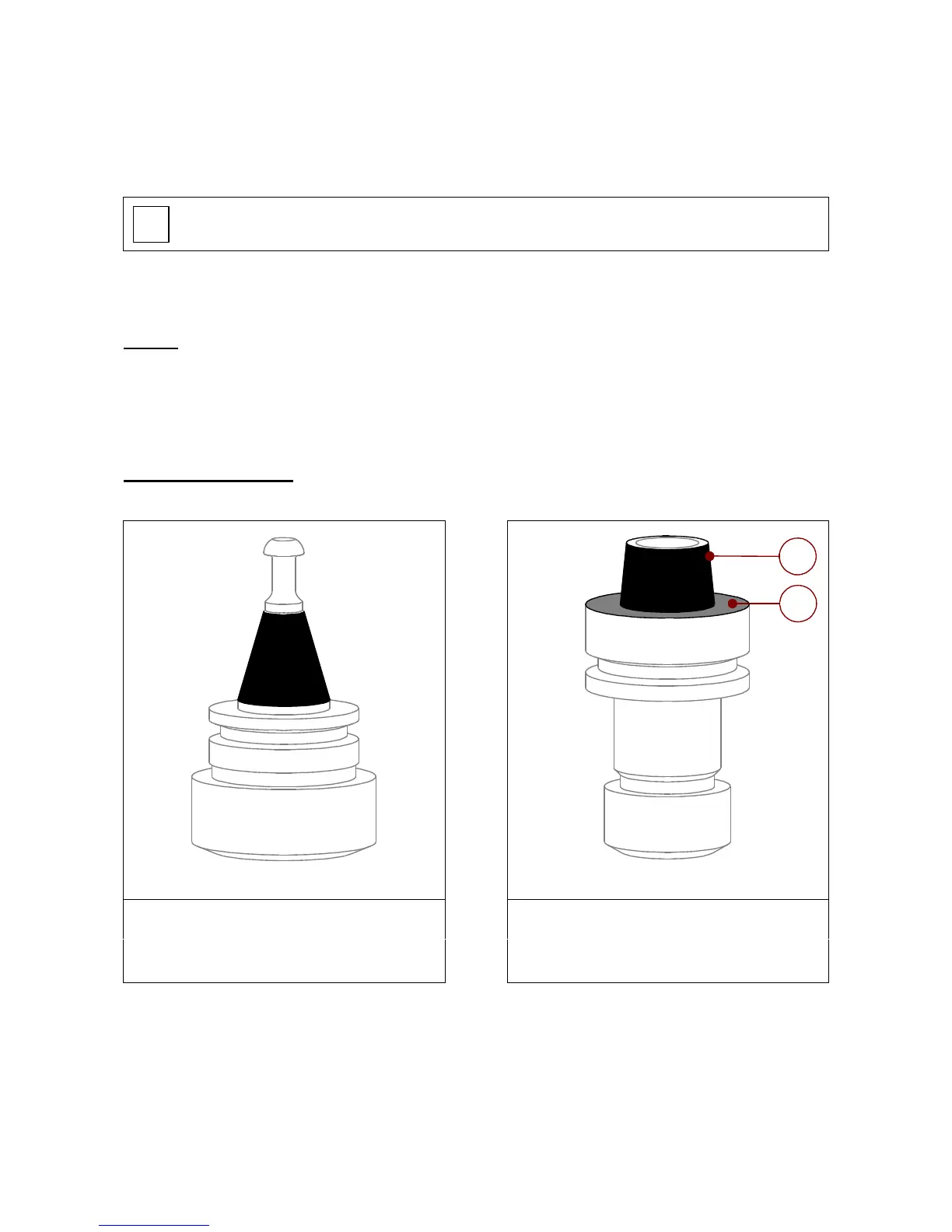

Always keep the conical surface of the tool holder (shown in black in Figure 12.1 and Figure 12.2)

and that of the housing in the spindle shaft (shown in black in Figure 12.3 and Figure 12.4) perfectly

clean and free from dust, grease, coolant, oil, metal shavings, and corrosion or lime scale. Check

these before you start to use the electro-spindle.

HSK VERSION ONLY: Make sure that the faces of the tool holder and spindle shaft (shown in

grey and identified by No. 2 in Figure 12.2 and Figure 12.4) are clean too.

ISO 30

2

1

HSK

HSK tool holder:

(1) Conical surface (in black)

Figure 12.1 Conical surface of an ISO 30 tool

holder (in black)

Figure 12.2

(2) Face (in grey)

Loading...

Loading...