______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 53/98

11.4 SELECTING THE TOOL HOLDER AND TOOL

11.4.1 ISO 30 tool holders

Always respect the following conditions when selecting a tool holder:

• Cone geometry must comply with DIN 69871 standard.

• Use only ISO 30 tool holders of AT3 precision rating.

• Do not use tool holders that have lumps, hollows, or other shapes that could affect dynamic

balancing.

• Dynamic balancing must be better than G=2.5 (ISO 1940 standard) at the electro-spindle's

maximum rated speed.

• Balancing must always be done with the tool assembled (pull stud, cone, elastic collet, ring nut,

tool).

• Only use pull studs (also referred to as retention knobs) provided by HSD (code 0804H0009).

Proceed as follows to install the pull stud in the ISO 30 cone:

• Thoroughly clean the mating surfaces of the pull stud and its seat.

• Smear the threads of the pull stud with LOCTITE 270 (or similar thread locking compound).

• Tighten the pull stud in place to a torque of 62 Nm.

• Leave the cone rest for at least 12 hours, so that the thread locking compound grips (or follow

the instructions of the locking compound manufacturer, if you have used an alternative to

LOCTITE 270).

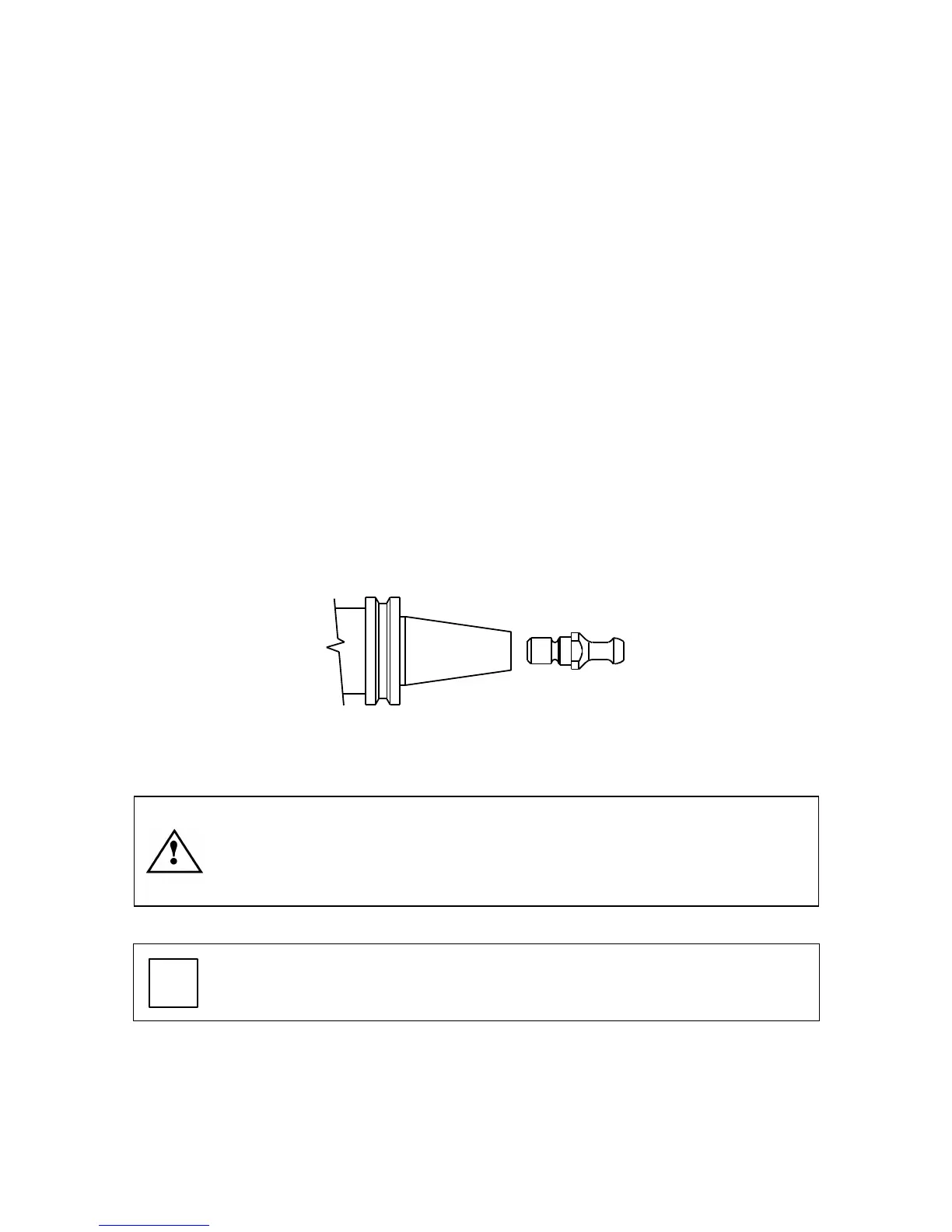

Figure 11.1

ISO 30 CONE

DIN 69871

HSD 0804H0009

PULL STUD

WARNING: Incorrect installation or the use of non-original HSD pull

studs can lead to the tool holder cone being thrown from the electro-

spindle.

Use only pull studs (or retention knobs) from HSD (code 0804H0009).

Loading...

Loading...