______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 50/98

§ 10 GENERAL CHECKS AFTER INSTALLATION AND DURING

START-UP

10.1 CHECKING THE ELECTRO-SPINDLE BEFORE START-UP

Positioning

• There must be at least 100 mm of free space behind the cooling fan cover.

Compressed air connections

• The internal pressurization and cone cleaning air hose must have an external

diameter of 8 mm, and must deliver dry, filtered air at a pressure of 4 bar (58 psi).

• The tool change air hose must have an external diameter of 8 mm, and must

deliver dry, filtered air at a pressure of 7 bar (100 psi).

• (For connection details see the labels on the unit itself and see also section 9.4

above).

THE TOOL RELEASE CYLINDER IS

SINGLE ACTING.

Electrical connections

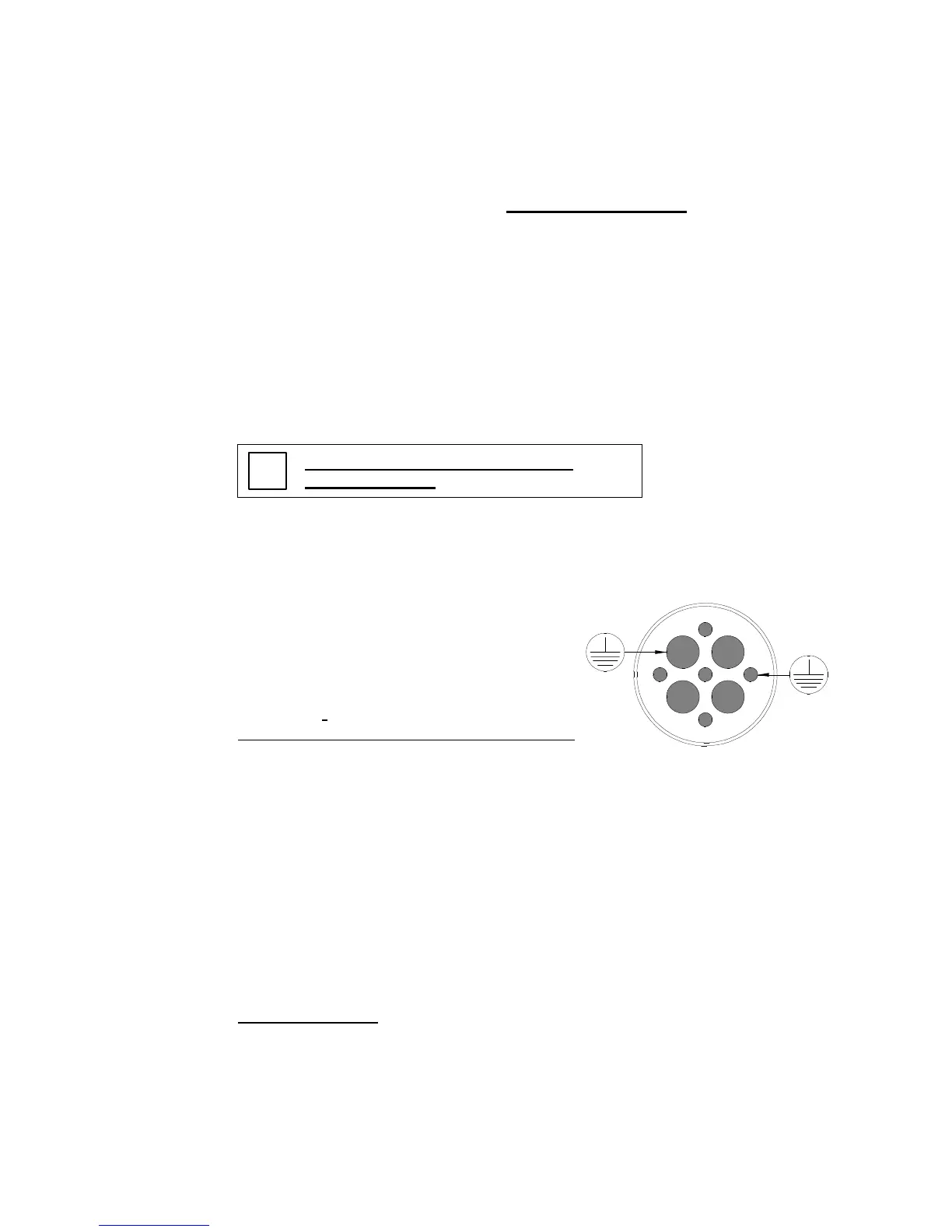

• The ground wire of the electro-spindle and

cooling fan must be connected to the ground

(pins 2 and 7 of the power connector in the

figure on the right).

• The motor's thermal switch (NC switch) must

be connected in series with the machine's

safety stop system (pins 1 and 5 of the power

connector in the figure on the right and section

9.6.4 above).

• 2 pole 220V - 380V configurable motors only:

The connections in the terminal block (380 V

star or 220 V delta) must match the electro-

spindle power. (See section 9.6.6 and § 7.)

2

5

3

4

6

1

8

9

7

Inverter programming

• The maximum power voltage setting must match the value on the electro-spindle's

data label.

• The minimum frequency value at which maximum voltage is delivered (rated

frequency, also referred to as knee or bend frequency) must match the value on

the electro-spindle's data label.

• The maximum frequency value must match the value on the electro-spindle's data

label.

• The maximum continuous current value must match the value on the electro-

spindle's data label.

• Contact HSD S.p.a. if you wish to check other inverter parameters.

Loading...

Loading...