______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 64/98

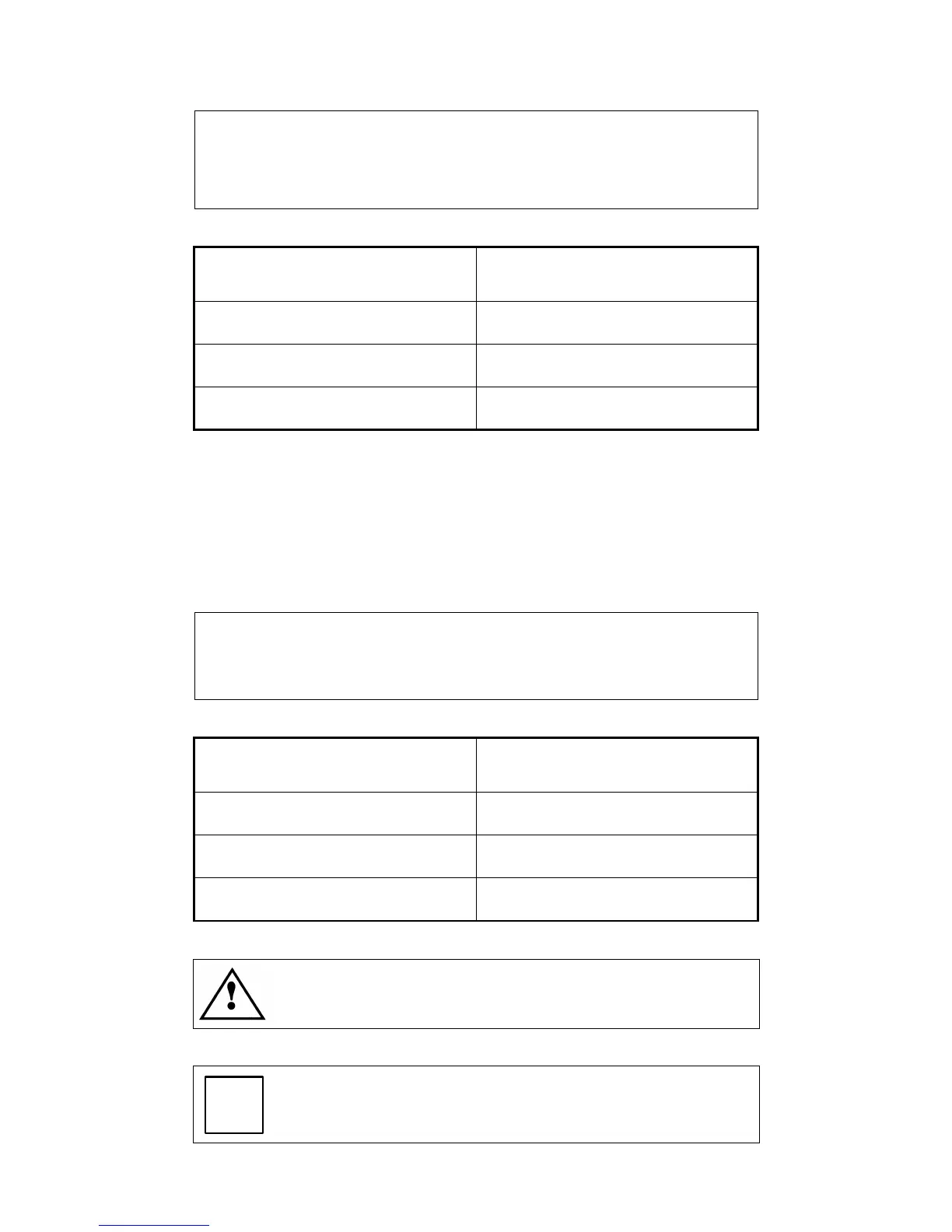

S2

Important during tool changes. Detects ejection of the

tool holder, permitting the next phase in the tool change

cycle to take place.

CONDITION

OUTPUT S2

Tool holder locked 0 V

No tool holder 0 V

Tool holder ejected

(collet open)

+24 V

11.6.2 HSK F63 versions

HSK F63 versions are fitted with three electro-spindle sensors: S1, S2 and S4. S1 and S4 are

connected in series and provide a single output. S1, S2 and S4 perform the functions described

below.

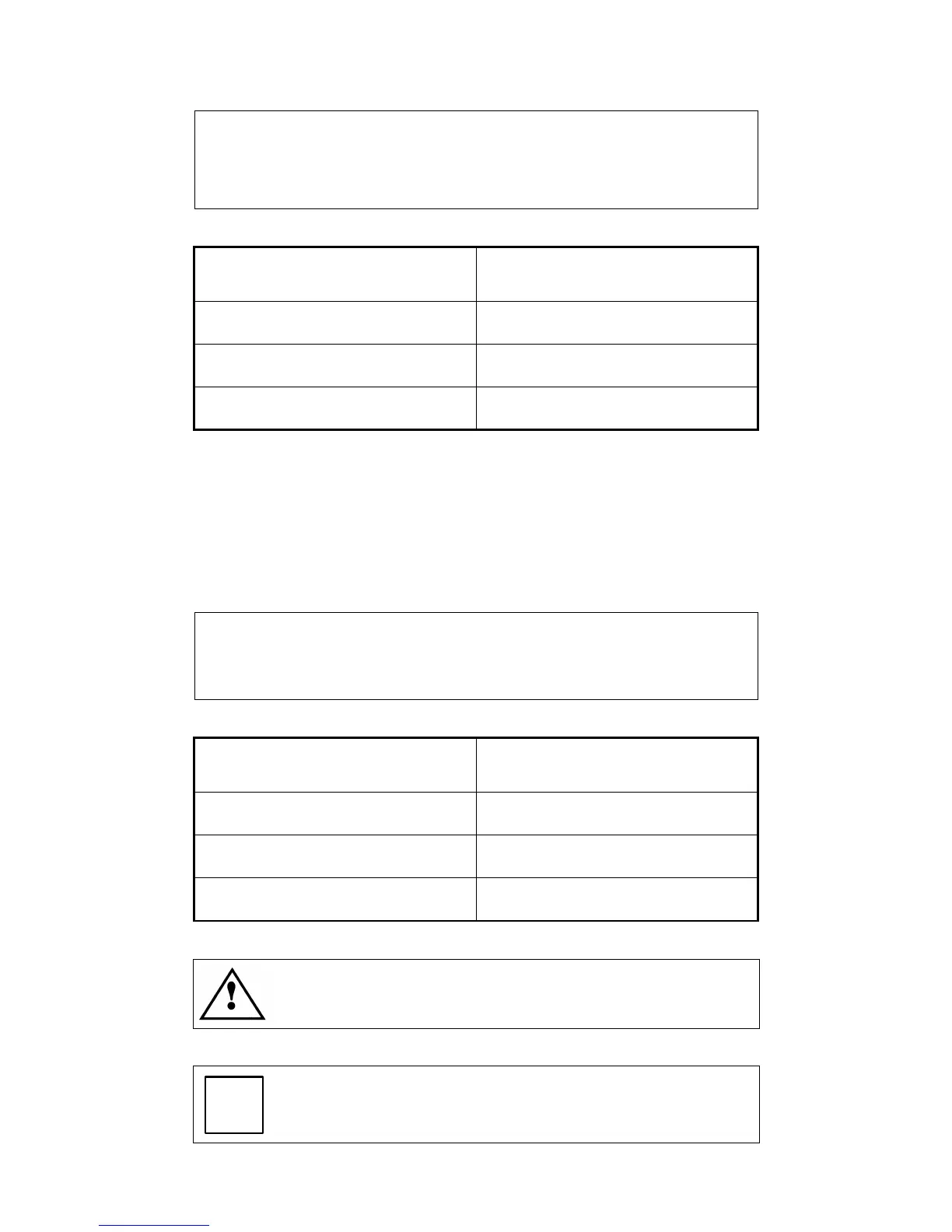

S1 + S4

Wired in series to detect correct locking of the tool

holder. Their output is used to provide the NC with a

safety signal permitting spindle rotation.

CONDITION

OUTPUT <S1+S4>

Tool holder locked +24 V

No tool holder 0 V

Tool holder ejected

(collet open)

0 V

Always monitor the output from <S1+S4> during electro-

spindle rotation and stop rotation if it drops to 0 Volt.

Ignore <S1+S4> from the moment the tool eject command

is given until the next tool locking command is given.

Loading...

Loading...