______HSD Technological equipment for Automation _____________________________________

5801H0017 Rev. 02 _________________________________________________________ 40/98

§ 9 INSTALLATION

9.1 FIRST CHECK

Before starting installation, check:

q That no part of the electro-spindle has been damaged during transport and/or handling.

q That the connectors are not damaged in any way.

9.2 PREPARATION OF THE EQUIPMENT REQUIRED FOR INSTALLATION ON

SITE

All work in preparation for installation of the electro-spindle is the responsibility of the customer

(e.g. preparation of electrical power supplies, compressed air etc.).

Make sure that the electrical power line to the electro-spindle is of adequate gauge and power.

Connection of the unit to the power supply must only be done by qualified electricians. The

customer is responsible for all parts of the electrical power supply to the electro-spindle.

The customer is expressly reminded that the electro-spindle must be correctly connected to earth.

Furthermore, the earth connection must comply with applicable regulations in the country in which

the unit is installed and must be duly checked and tested by a qualified electrician.

See below for the installation layout and connection diagrams.

9.3 MECHANICAL INSTALLATION

9.3.1 The supporting surface

The supporting surface on which the

electro-spindle is fixed must have a

flatness better than 0.02 mm.

0,02

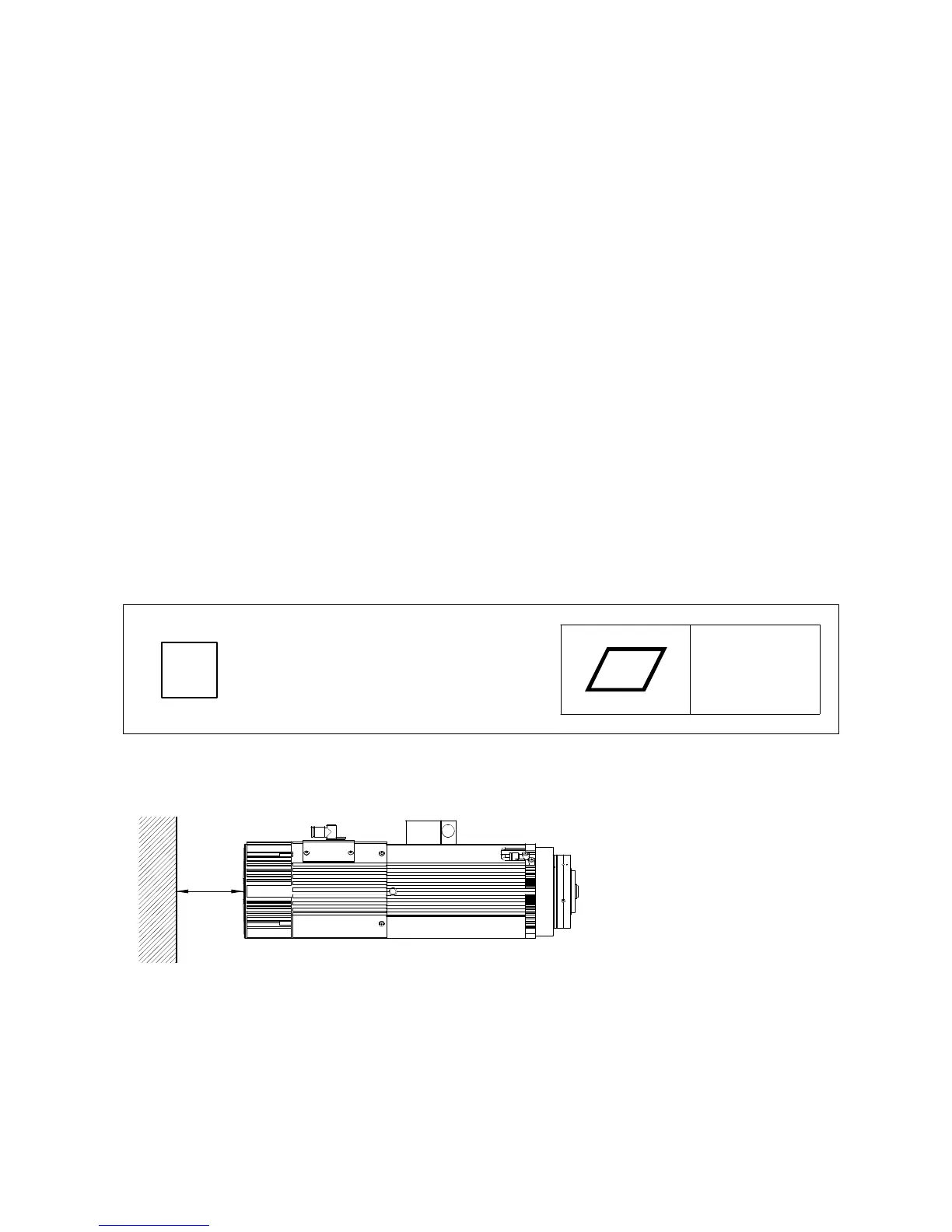

9.3.2 Positioning the electro-spindle

100

Figure 9.1 Minimum clearance of fan

The electro-spindle must be

installed with at least 100 mm

of free space behind the

cooling fan cover to ensure an

adequate flow of cooling air.

Loading...

Loading...