10 | Routine Operation INFICON

252 / 319 074-594-P1H Micro GC Fusion Operating Man-

ual

10.2 Column Conditioning

Over time, small amounts of contaminants may accumulate in the analytical column

causing ghost peaks, peak tailing, and/or retention time shifts. Column temperature

programmed methods can be optimized to flush contaminants and high boiling point

compounds with each run, however, a column bakeout may occasionally still be

needed. A bakeout should be performed:

• after the initial installation

• after installing a replacement GC module

• after Micro GC Fusion has been powered off or stored for an extended period of

time

• after Micro GC Fusion has been stored in a shipping case for an extended period

of time

• periodically as needed to refresh column performance

10.2.1 Bakeout from System Status

Perform the following steps to implement a bakeout on Micro GC Fusion. Depending

on the column type, bakeout temperatures will be set according to the isothermal

temperatures indicated in Create a Custom Bakeout Method [}253].

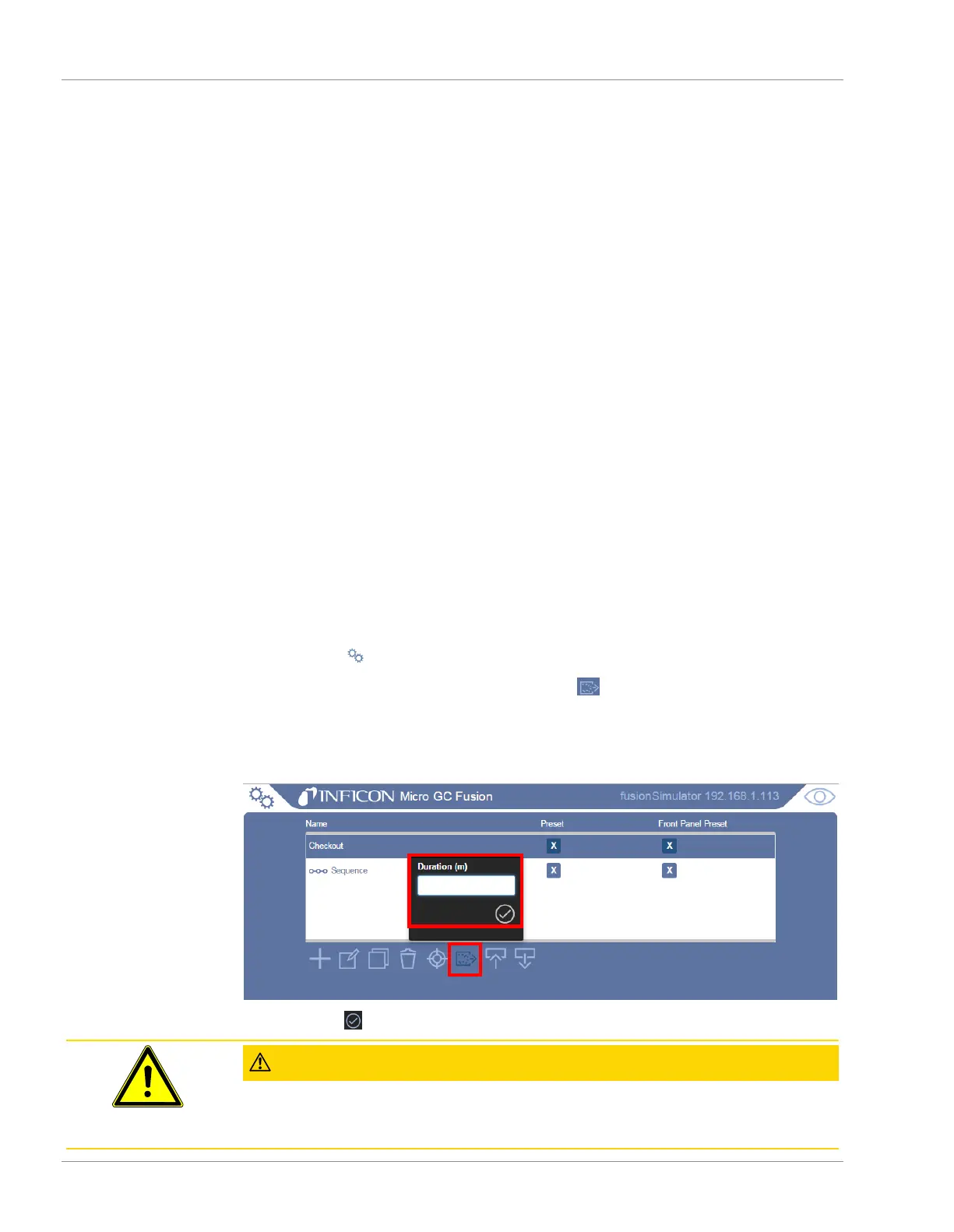

1

Click the icon.

2

Click

Methods/Sequences

, followed by the icon.

3

Type a bakeout duration in minutes. The bakeout duration should be within the

isothermal temperature duration described in Create a Custom Bakeout Method

[}253].

4

Click the icon to begin the bakeout operation.

CAUTION

Carrier gas must be on (flowing) during a bakeout to avoid damaging

Micro GC Fusion.

Loading...

Loading...