Maintenance

Re-assemblyisdoneinreverseorder.Ensurethatthetireis

replacedonthesamesideandinthesametraveldirectionas

itwaspreviouslymounted.

Repairingtheflattire

CAUTION!

Riskofexplosion

Thewheelwillexplodeifyoudonotlettheairoutof

thetirebeforeremovingthewheel.

–Alwayslettheairoutofthetirebeforeremovingit

(pressinthepininthemiddleofthevalve).

1.Unscrewvalvecap.

2.Depressurisetirecompletelybypressinginthepininthevalve.

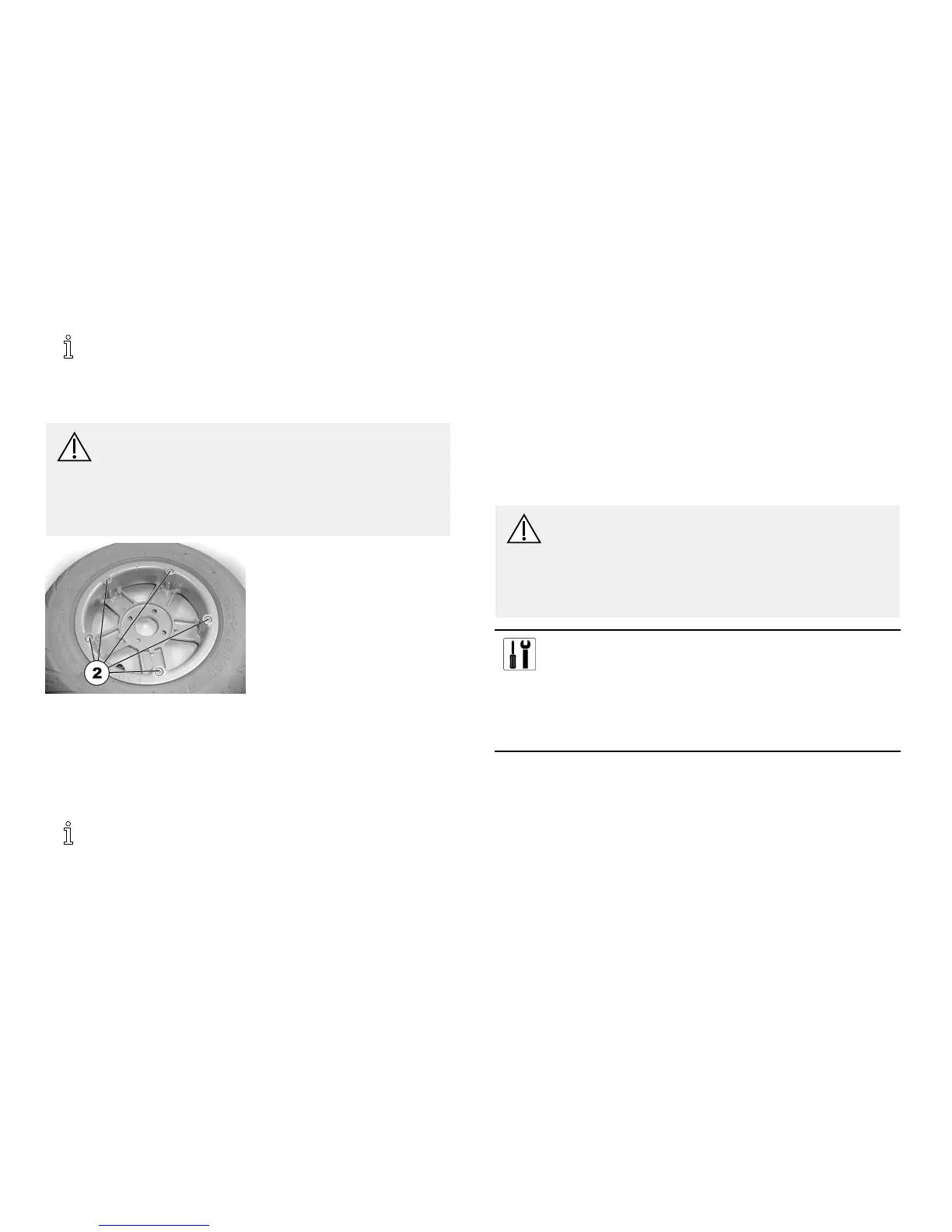

3.Removethe5cylinderheadscrews(backofthewheel,2)

4.Removetherimhalvesfromthetire.

5.Removetheinnertubefromthetire.

6.Repairinnertubeandreplace,orinsertnew.

Iftheoldinnertubeistoberepairedandre-used,andhas

becomewetduringrepair,youcanmakereplacementeasier

bysprinklingtheinnertubewithalittletalcumpowder.

7.Insertthewheelrimhalvesfromoutsideintothetire.

8.Pumpalittleairintotheinnertube.

9.Reinsertthecylinderheadscrewsandtightento10Nm.Avoid

crushingtheinnertube!

10.Ensurethatthetireouterisseatedcorrectly.

11.Pumpthetireuptotheprescribedpressure.

12.Ensurethatthetireouterisseatedcorrectlyagain.

13.Screwthevalvecapbackon.

14.Refitthewheel.

9.4.2Repairingpunctures(drivewheelwithGB

motorandpneumatictires)

CAUTION!

Riskofinjury

Ifthewheelhasbeeninsufficientlytightenedduring

assembly,itcanbecomeloosenedduringdriving.

–Whenreassemblingthedrivewheels,tightentheAllen

screwsatatorqueof25Nm.

Requirements:

•Open-endedspanner6mm

•Torquewrench

•Repairkitfortirerepairoranewinnertube.

•Talcumpowder

•ScrewblockerLoctite(e.g.Loctite243)

1529686-P83

Loading...

Loading...