9

ASSEMBLY INFORMATION

EN 116

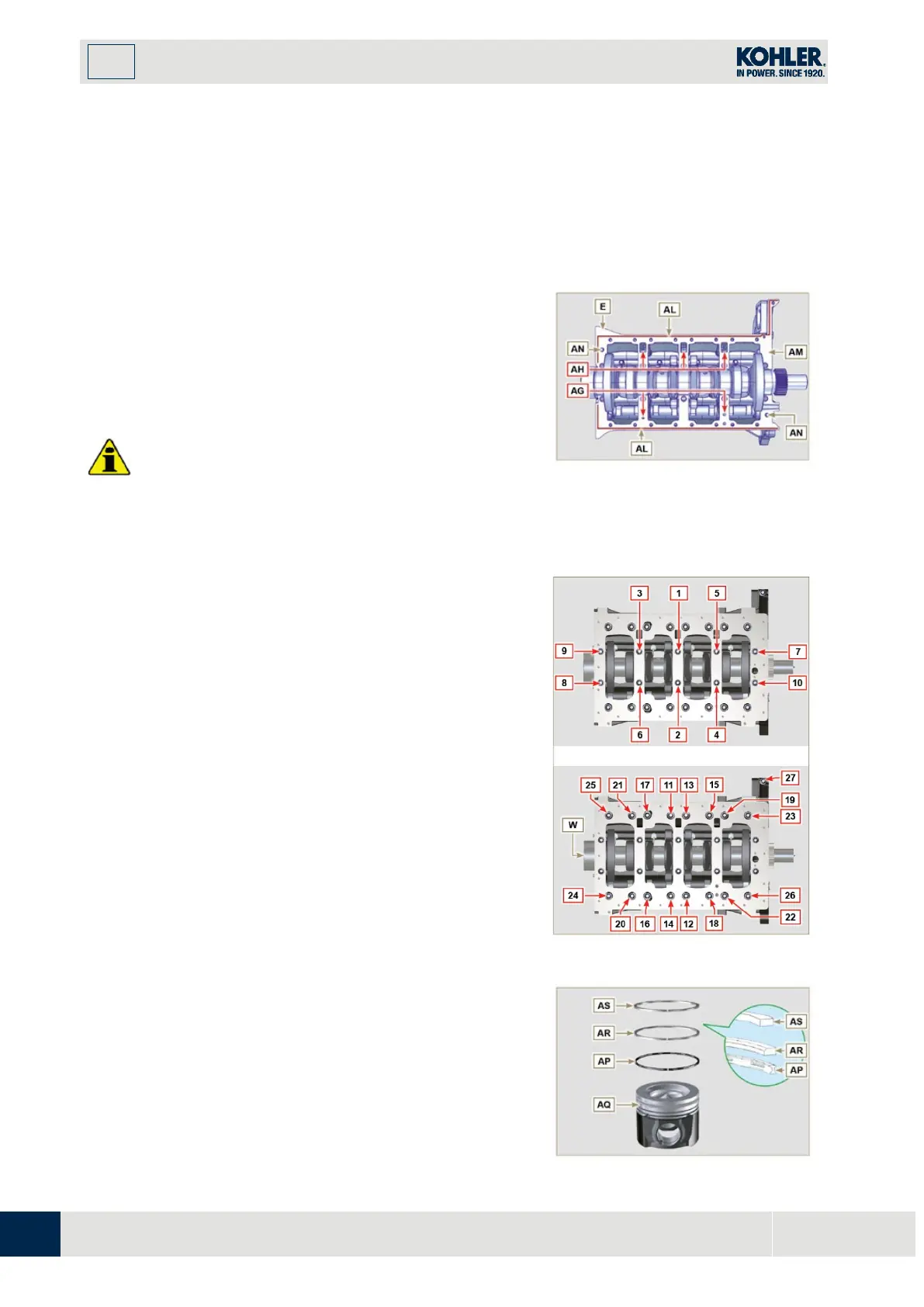

Check that the crankshaft half-bearings are mounted

correctly on the lower crankcase F (AC detail).

2.

Assemble the 2 shoulder half-rings AD onto the lower

crankcase F applying two drops of oil to keep them in

their seat.

3.

Check that the coupling surfaces AE are free from dirt

and grit.

Spread a bead of

of approx

mm thickness on the surface AM of the upper

crankshaft half C being careful not to block the oil feed

grooves AG and the return oil sump AH.

5.

Join the two crankshaft halves E and F observing the

guide pins AN.

I

mportant

•

Failure to follow the bolting procedures compromises

the functionality of the engine and can cause damag

e

to people and property.

Fig 9.8

6.

Tighten the fastening screws strictly following the

sequence and the tightening torque indicated.

Tightening Screws

Torx M12x1,25

(from the

n° 1

to the

n° 10

):

CYCLE 1 - with a torque of

40 Nm

;

CYCLE 2 - with a torque of

70 Nm

;

CYCLE 3 - with a torque of

120 Nm

.

Tightening Screws

Torx M8

(from the

n° 11

to the

n°

27

):

CYCLE 4 - with a torque of

20Nm

;

CYCLE 5 - with a torque of

35

Nm

;

7.

Perform the operations described in Par. 8.4.2.

8.

Check that crankshaft W rotates smoothly.

Fig 9.9

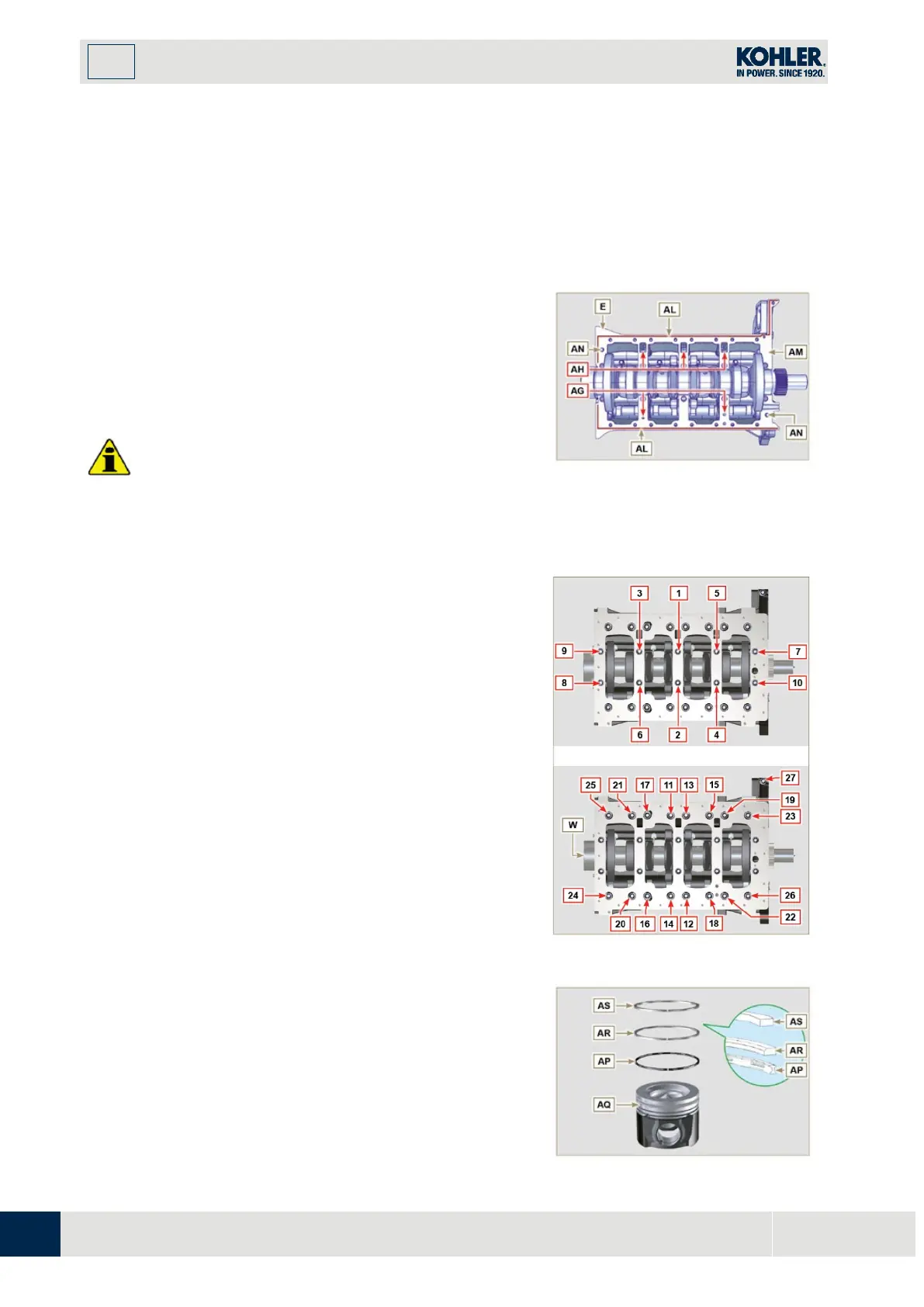

9.3.7 Piston rings

1.

Perform the operations described in Par. 8.5.3.

2.

Put the scraper ring AP onto the piston AQ.

3.

Put the 2° seal ring AR on the piston AQ.

4.

Put the 1° seal ring AS onto the piston AQ.

Loading...

Loading...