5-20 LeeBoy 8515E Conveyor Paver

Maintenance

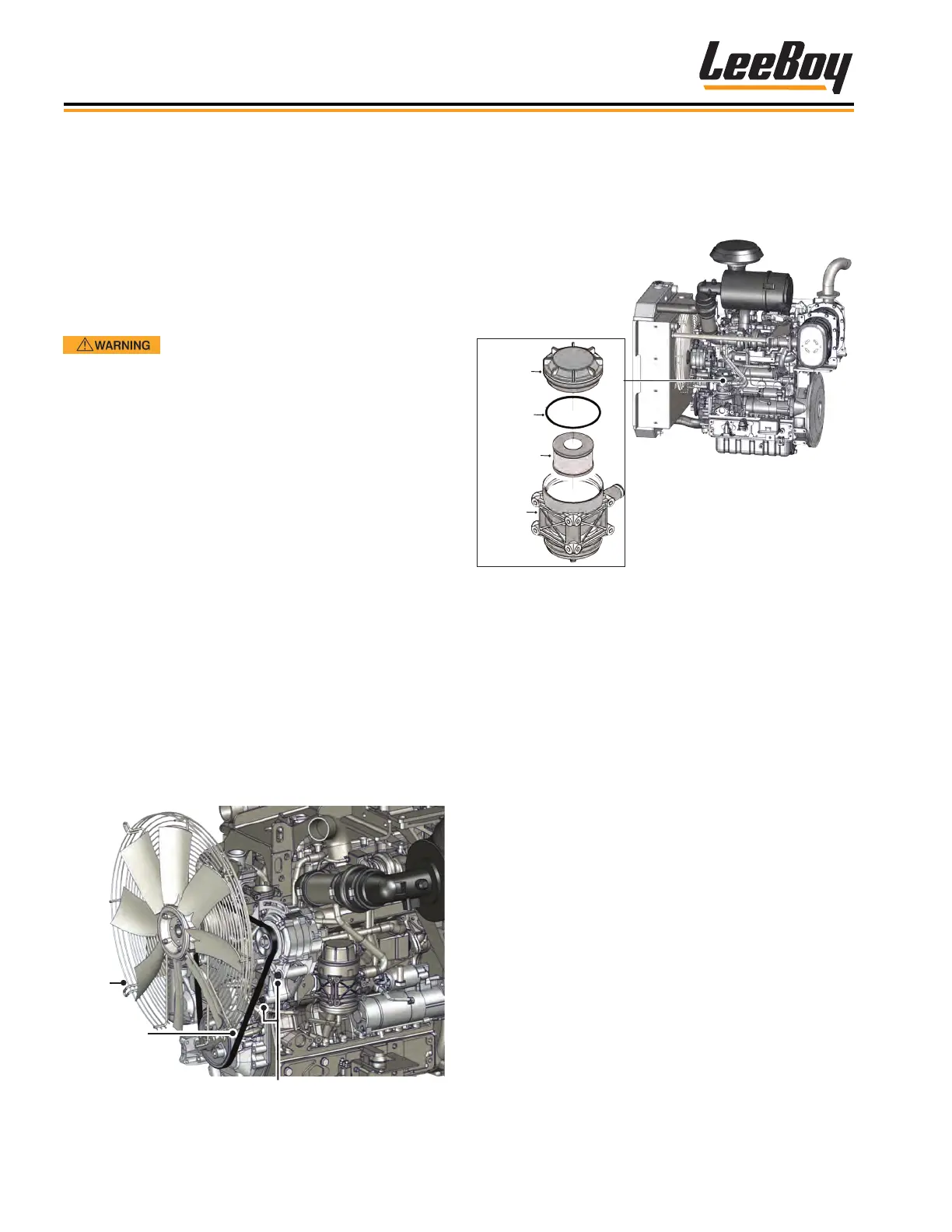

Change Oil Separator ElementChange Oil Separator Element

The oil separator captures oil mist carried over from the

lubrication process. The oil separator element must be

changed every 1500 hours of operation. (Figure 5-20)

Cap

O-Ring

Gasket

Element

Oil

Separator

Body

Replace the oil

separator element

every 1500 hours

of operation.

Figure 5-20. Oil Separator

To change the oil separator element:

1. Unscrew the oil separator cover cap and remove

from the body.

2. Remove the used gasket and lter element.

Dispose of in accordance with environmental laws

and requirements.

3. Wipe oil and grease off the oil separator body and

cover.

4. Insert a new lter element and gasket.

5. Reattach the cover cap to the oil separator body.

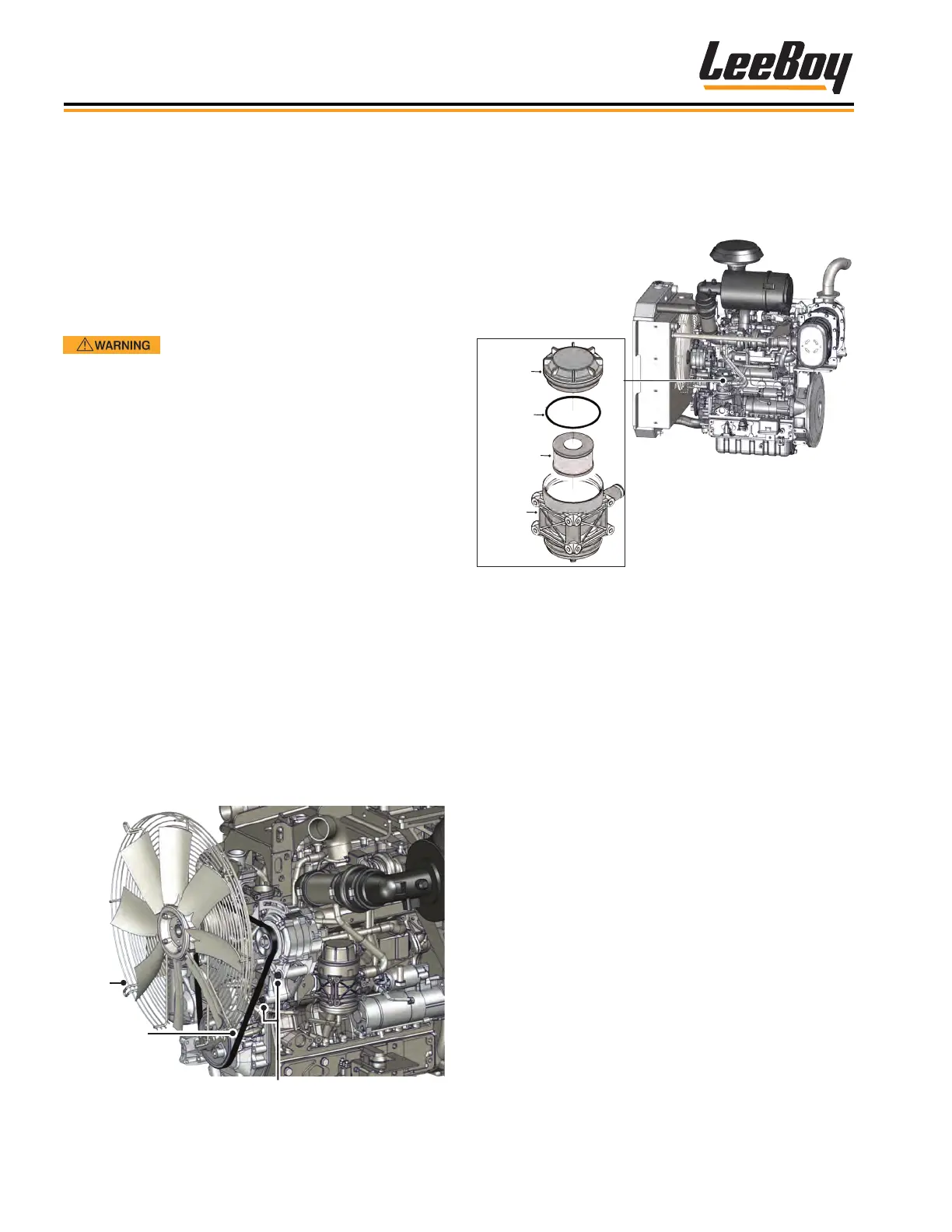

Engine Drive BeltEngine Drive Belt

Adjust the engine drive belt every 250 service hours

and replace it every 500 hours. Regardless of the

maintenance interval, the engine fan belt should be

replaced if it appears frayed or cracked. (Figure 5-19)

NOTE: If the fan belt is loose or damaged, and/or

the fan is damaged, it can result in overheating or

insufcient charging. Replace the fan belt and any

other damaged components immediately.

Engine must be turned off and the key

removed before checking, adjusting or replacing the

fan belt to avoid personal injury or even death.

To adjust or replace the belt:

1. Turn off engine and remove the key. Block the

wheels to prevent movement while working on the

machine.

2. Remove the safety shield.

3. Apply moderate thumb pressure to the belt between

the pulleys to gauge tension.

4. If tension is incorrect, loosen the alternator

mounting bolts and place a lever between the

alternator and the engine block.

• If adjusting the belt, pull the alternator out until

the deection of the belt (when pressed in

the middle of the span) falls within .39 to .47

inches.

• If replacing the belt, remove worn belt and

replace with new fan belt.

5. Retighten the alternator bolts and reinstall safety

shield.

Safety

Shield

Fan Belt

Figure 5-19. Engine Belt

Loading...

Loading...