44

LeeBoy 8515E Conveyor Paver 4-21

Operation

Heating the ScreedHeating the Screed

Heating the screed helps prevent hot mix from sticking

to the cold screed plate and produces a smooth, tight

mat surface. This should be performed before paving

and if the paver is idle long enough for the screed to

cool between loads.

Allow the screed (and screed extension) to heat 15

minutes before beginning to pave.

NOTE: Lower the screed two inches off the ground

while heating to prevent cold air and wind

from affecting the heating process.

NOTE: You can set the screed directly onto a fresh

mat of hot asphalt while running the heating

system, allowing the heat of the asphalt to

help heat the screed plate.

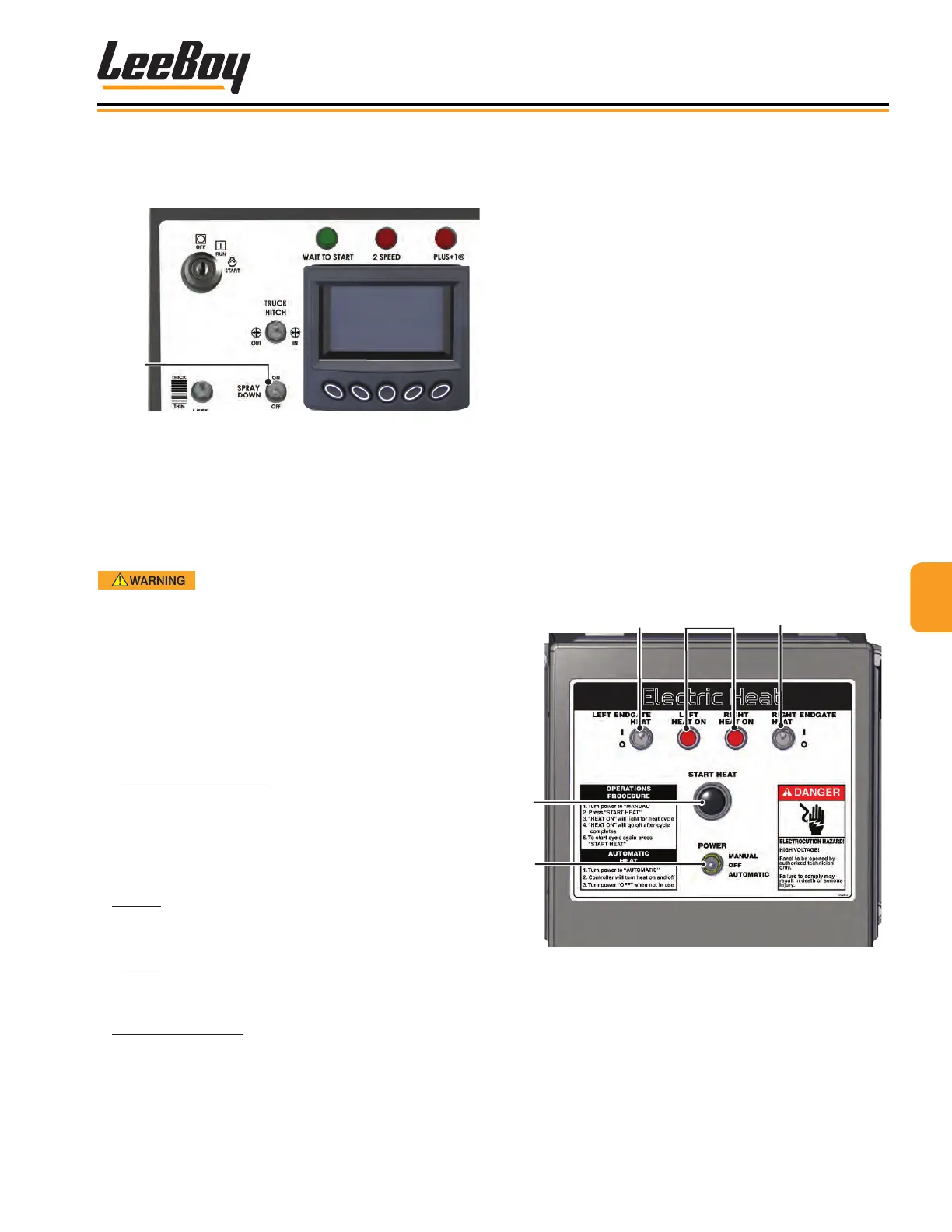

The LeeBoy 8515E Conveyor Paver is equipped with an

electric heat system that heats the screed and screed

extensions. A hydraulically-driven generator powers the

electric heat control box mounted in the center on the

rear side of the machine. This control box is where you

will select the heating function before you begin to pave.

(Figure 4-41)

4

5

Figure 4-41. Electric Heat Control Box

1 - Left End Gate Switch (OPTION)

2 - Heat On Lights

3 - Right End Gate Switch (OPTION)

4 - Start Heat Button

5 - Power Switch

To operate the Spray Down system:

1. Turn the Spray Down switch on the control panel UP

to the ON position. (Figure 4-40)

Spray

Down

Switch

Figure 4-40. Spray Down Switch

2. Extend hose from the reel.

3. Squeeze the wand handle and spray area. Release

the wand handle when nished.

4. Turns the Spray Down switch on the control panel

OFF.

Never spray cleaning solvent or

release agent near the screed heating element or

near open ame. These agents are highly ammable

and can ignite, causing serious personal injury.

Start at the front of the machine and work rearward,

using a scraper if necessary, paying particular attention

to ensuring built-up material is removed from:

• Push Rollers: Rotate the rollers while cleaning and

soak bearing ends to maintain free rotation.

• Hopper and Conveyors: Thoroughly clean surfaces

and any material accumulating in chains, drive

sprockets, idler shaft, bearings and tunnel areas.

AFTER cleaning the machine, operate the conveyors

briey to carry solvent into return areas where it can

help dissolve hidden asphalt material.

• Augers: Scrape away any accumulated material

around bearings and clean contact surfaces down to

the metal to avoid quick build-up while paving.

• Screed: Face and bottom plates should be clean and

smooth on the main and screed extensions to achieve

a smooth paving mat.

• Operator Platforms: Be sure to wash away solvent

residue so walk boards and operator platforms do not

remain slippery.

Loading...

Loading...