5-34 LeeBoy 8515E Conveyor Paver

Maintenance

Capscrew

(or Bolt)

+

+

Grease

Shaft

Splines

Capscrew

(or Bolt)

O-Ring

(Required)

Figure 5-39. Hydraulic Motor Mount

To avoid contamination:

• Remove all matter from around the ports of the

motor and the threads of ttings.

• Fill the case of the motor being used (piston-type,

gear motor, gerotor motor, geroller motor or vane

motor) with clean hydraulic uid through the highest

case drain port and connect the case drain line.

Failure to do so will result in damage to the motor

through inadequate lubrication on start-up.

• Units that are mounted vertically with the shaft up

require special attention to ensure the uid level in

the case is high enough to lubricate the front shaft

bearing(s).

Once all system connections are made, the motor

should be run for 15 - 30 minutes at no-load and half-

speed to bleed air from the hydraulic system.

Torque HubTorque Hub

If the torque hub has been damaged or worn, use to

following procedures for replacement.

1. Park paver on a level surface.

2. Raise the hopper and insert safety prop. (Page

5-5)

3. Jack up the paver at least two feet and place on

sturdy jack stands.

4. Place blocks sufcient to support the hydraulic

motors underneath them. (Figure 5-37 on Page

5-33)

NOTE: Mark location of torque hub to the

undercarriage before removing to ensure the

drive motor is reinstalled in the same position.

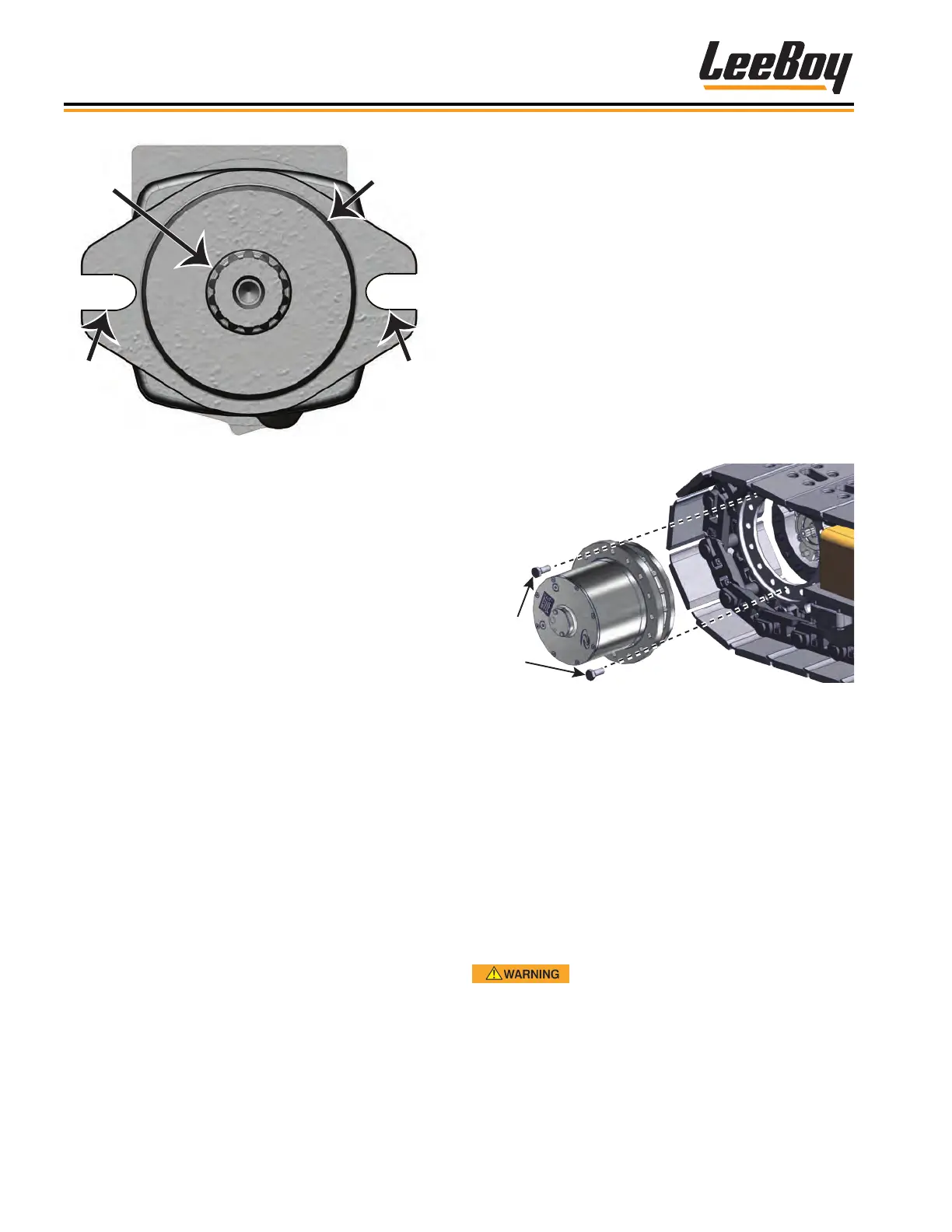

5/8-Inch

Bolts

(16)

Figure 5-40. Torque Hub

5. Remove the 16 5/8-inch bolts and carefully remove

torque hub. (Figure 5-40) Check O-Ring on the

hydraulic motor and replace if worn.

6. Install new torque hub into position to align with the

hydraulic motor. Place thread-locking adhesive on

torque hub bolts and torque bolts. (See Torque

Specications in Section 2)

7. Fill torque hub with oil. (Page 5-11)

8. Lower paver to the ground.

9. Start paver and check for any leaks with engine

running.

Stop the engine immediately if any

hydraulic leak is noted. DO NOT start the engine

until the leak has been repaired.

Loading...

Loading...