3-4 LeeBoy 8515E Conveyor Paver

Component Location

AugersAugers

Right and left augers

rotate to move material

from the conveyors to the

screed. The auger can

be manually controlled

at the operator platform

or by a screed operator

on the screed using a

remote screed control

box.

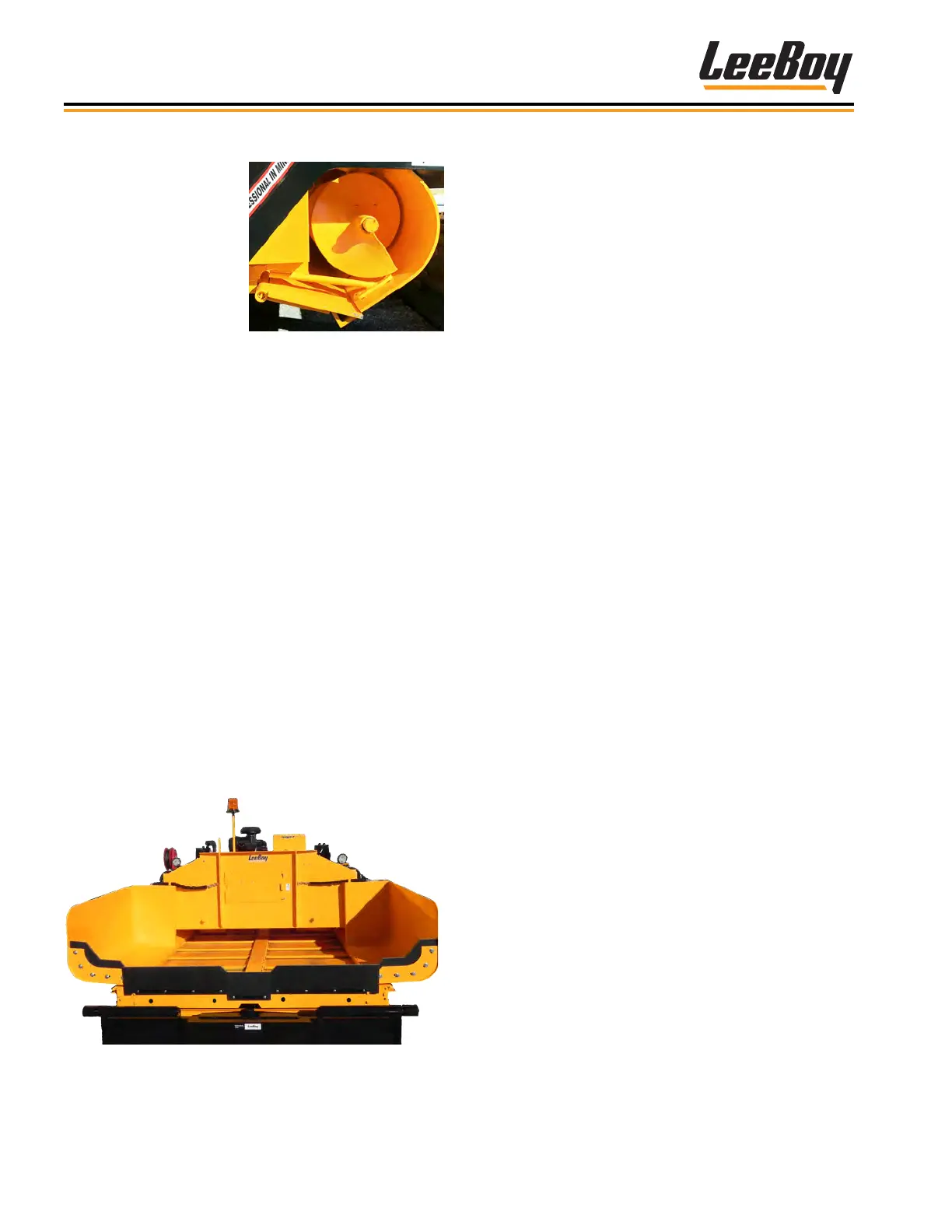

ScreedScreed

The screed is the last component that contacts the

paving material. Asphalt material is fed from the hopper

conveyor through the augers to the screed.

The LeeBoy 8515E Conveyor Paver is equipped with the

Legend® screed system that is electrically heated. The

optional Heavy Duty HD815 screed is also available. The

main screed has hydraulically-controlled extensions on

each side that extend and retract to allow paving widths

from 8 - 15 feet. Hydraulically-driven dual vibrators

mounted on the main screed frame increase paving

material compaction. The screed can be locked in the

raised position for travel, service and overnight parking

for additional stability.

The optional HD815 screed features heavy-duty ight

screws, heavy-duty crown and valley mechanism and

3-Adjuster AOA (Angle of Attack) with vertical height

adjustment for even more screed control.

Hydraulic SystemHydraulic System

The hydraulic system includes hydraulic pumps, motor

and cylinders that work together for optimum machine

component control. Valves regulate the directional,

pressure and uid ow throughout the hydraulic system.

The LeeBoy 8515E model is now equipped with

additional hydraulic oil cooling components for

smoother operation. Hydraulic test ports add ease and

convenience for checking pressure for the paver’s main

functions.

Electrical SystemElectrical System

The battery produces 12 volts DC and maintains 1,125

cold cranking amperes (CCA). An engine-mounted

alternator with a minimum of 60 amperes charging

capacity keeps the battery charged during normal

operation.

Heating controls provide the necessary connection and

control of the output power from the generator to the

heating elements. Each element is sized to t properly

in your screed, and provide sufcient power to heat

your screed plate to a temperature so asphalt material

will not drag or stick to the lower surface of the screed

plate. The heating control is mounted near the middle of

the main screed and is easily accessible to the screed

operator when a heating cycle is required.

The auger can also be controlled automatically using

the auger sonic sensor system. The sensor is mounted

on the screed endgates and used to monitor and control

the pile height of material at the discharge end of the

augers.

Hopper and ConveyorsHopper and Conveyors

Hydraulic power raises and lowers the hopper wings.

The hopper wings can also be locked into place in

the closed position for transport. When fully open, the

hopper can hold a payload up to 7.5 tons.

Material in the hopper is moved toward the back of the

paver to the screed by conveyors. Its wide, automatic

conveyors with a wide hopper design delivers asphalt

more evenly and efciently to produce a smooth asphalt

mat.

The conveyor bed can be lifted hydraulically, allowing

easy access to the paver undercarriage and tracks for

service and cleaning.

Loading...

Loading...