5-32 LeeBoy 8515E Conveyor Paver

Maintenance

REPLACEMENT PROCEDURES

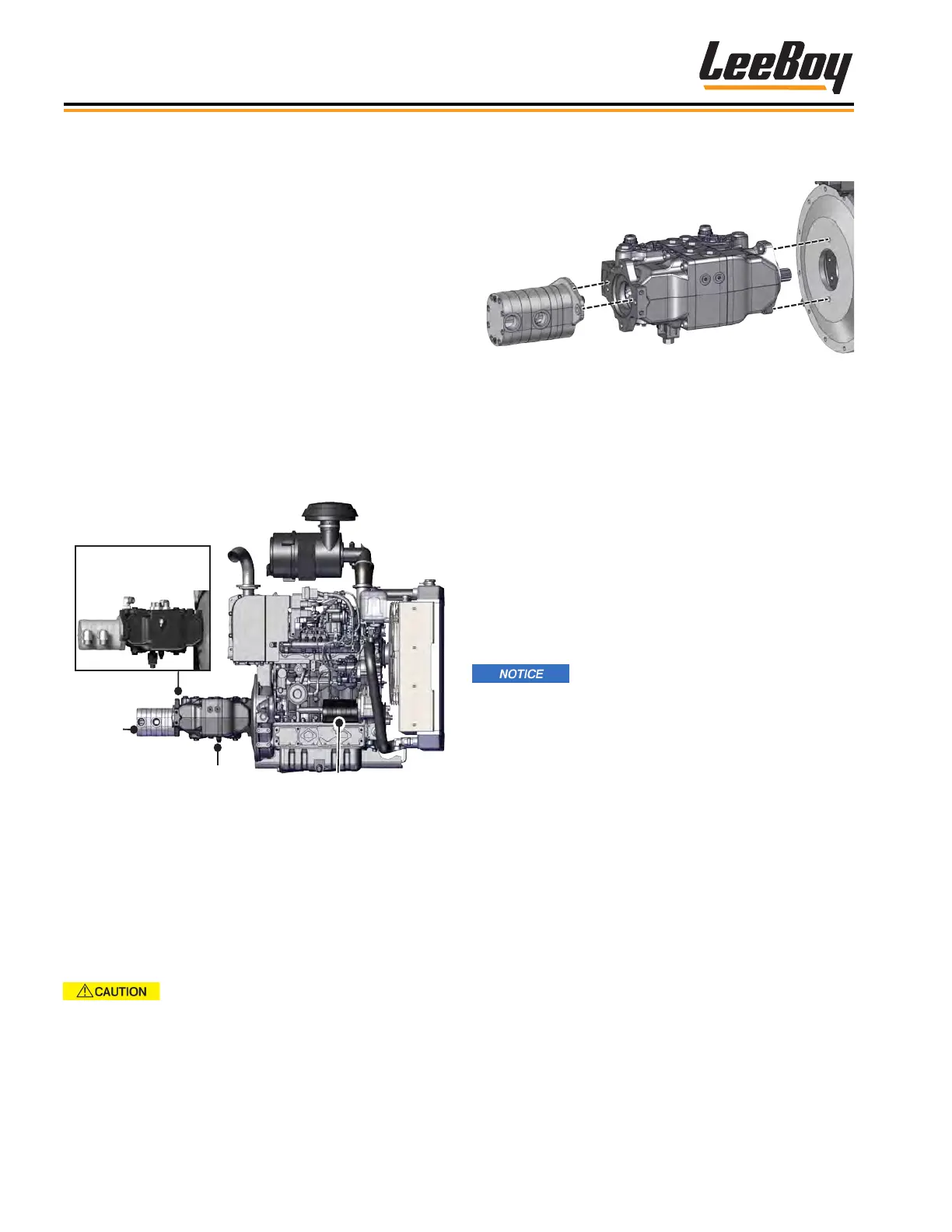

Gear PumpsGear Pumps

Hydraulic uid is transmitted throughout the machine to

motors and cylinders, becoming pressurized according

to the resistance present. The uid is controlled by

valves and distributed through hoses and tubes. The

tandem propel (drive) pump, tandem pump, and tandem

axillary pump play a signicant role in producing

hydraulic power by supplying hydraulic uid to system

components. (Figure 5-35)

The tandem ear and tandem drive pumps are accessible

from the right side of the paver. The tandem gear pump

is attached tot eh tandem drive pump (just behind it).

Both are easily reached via the left access panel. The

auxilliary gear pump is easier to access from the front

access panel inside the hopper.

Tandem

Gear Pump

(Augers)

Tandem

Drive Pump

Tandem Auxilliary

Gear Pump

(Charge and Conveyors)

Electric Screed

Tandem Gear Pump

Figure 5-35. Tandem Gear Pumps

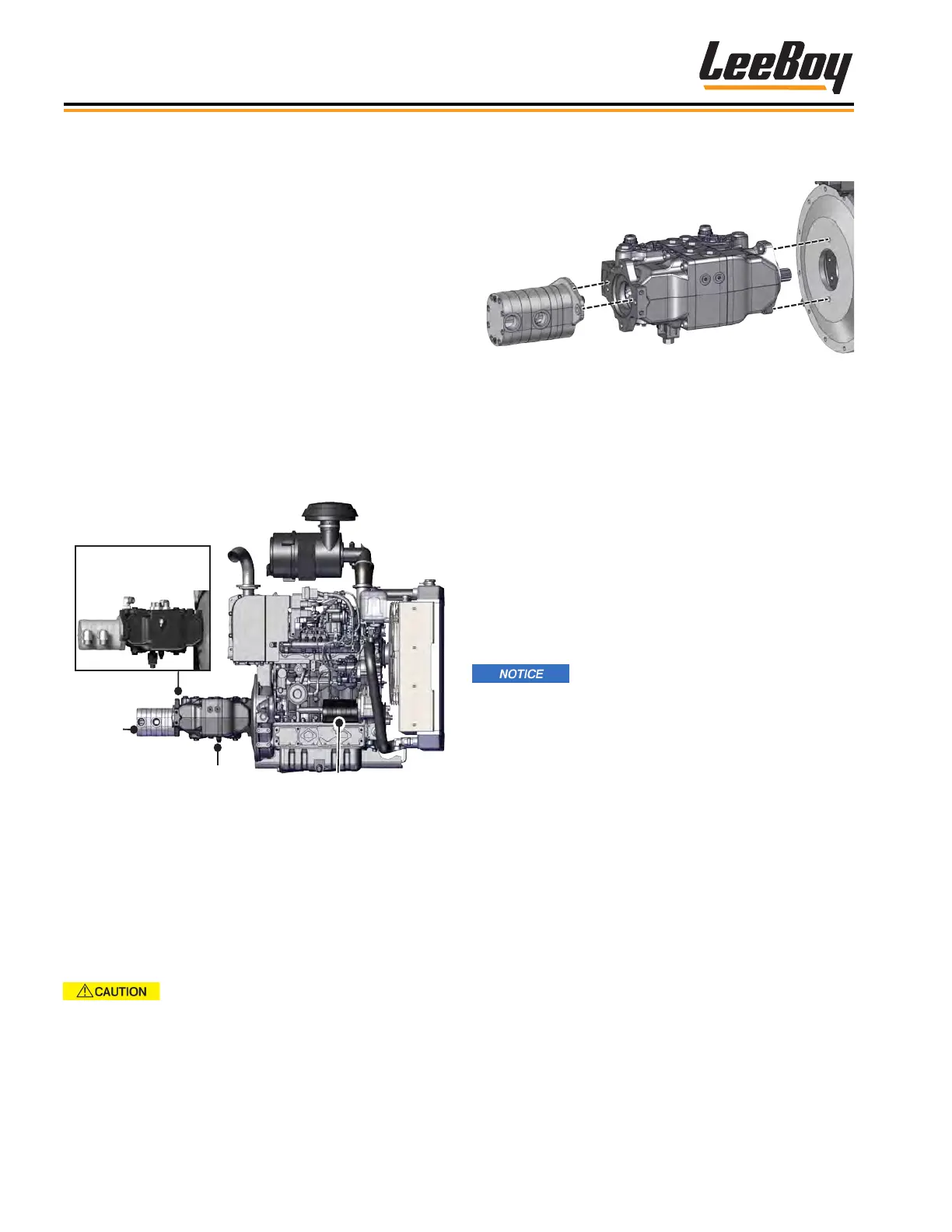

Use the following procedure for replacing either of the

pumps:

1. Access the pump slated for replacement.

2. Label and disconnect the hoses to the pump,

capping the hoses and ttings on the pump.

The gear pump assemblies are very

heavy and must be properly supported with a sling

before continuing the following steps. DO NOT

loosen mounting bolts unless the pump is sufciently

supported.

3. Remove the two bolts on the pump mount (one on

each side of mount). (Figure 5-36)

Propel Pump

Bolts (2)

Tandem

Pump Bolts (2)

Figure 5-36. Hydraulic Pump Assemblies

4. Using the sling, carefully lift the pump assembly out

of the machine and place on a at surface.

5. Remove and inspect the O-ring(s) on end of the

pump for wear or damage. Replace if needed.

6. Put a small amount of hydraulic oil onto the O-Ring

and reinstall.

7. Align the new pump with the two mounting holes and

reattach pump.

8. Refer to Torque Tables in Section 2 and torque

bolts.

9. Prell the pump with hydraulic oil.

Failure to prell the pump before

starting the engine can damage the pump.

10. Remove plug caps and reconnect hydraulic hoses

to pump as previously labeled.

11. Check hydraulic oil level. Add more if needed.

12. Turn the ignition key to Start without starting the

engine a few times to “bump” the engine enough

for hydraulic oil to ow to the pump, then start the

engine.

13. With the engine running, check for leaks.

14. If no leaks are noted, let machine idle approximately

10 minutes to allow the pump and motor cases to ll

with hydraulic oil before operating.

Loading...

Loading...