33

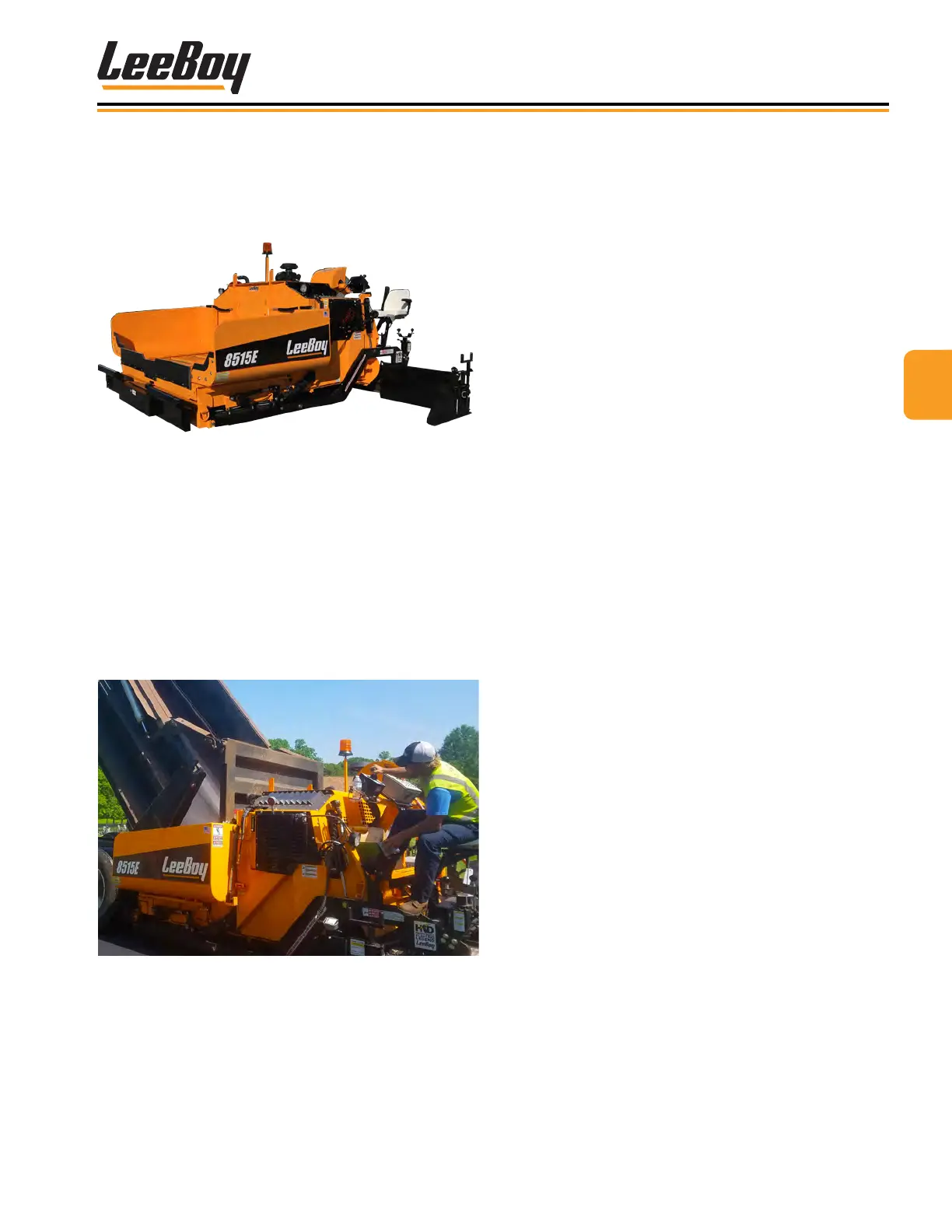

LeeBoy 8515E Conveyor Paver 3-3

Component Location

EngineEngine

The LeeBoy Model 8515E Conveyor Paver is equipped

with a Kubota V3800-TIE4F, 74 HP diesel engine--a

strong performer with the latest technology. The engine

is accessible through several access doors, with a front

service door where fuel lter components are located

for easier access.

This electronically-controlled engine offers the latest in

innovative emission solutions that comply with stringent

regulations (EPA/CARB Tier 4 and EU Stage IIIB) for

exhaust after-treatment that optimizes combustion. This

Tier 4 Final fuel-efcient engine complies with emission

requirements established by the U.S. Environmental

Protection Agency (EPA) to reduce diesel particulate

matter (DPM) and other toxins released into the air.

Advanced emission-control devices and low-sulfur fuel

requirements--only Ultra-Low Sulfur Diesel (ULSD) can

be used in these engines--combine with after-treatment

methods such as Exhaust Gas Recirculation (EGR) and

Diesel Particulate Filters (DPF).

The air cleaner removes ne particles such as dust,

sand, chaff and lint from the air. As air is taken into the

air cleaner assembly, the cyclone action deposits some

of the ne particles in the evacuator that is mounted

on the bottom of the air cleaner housing. The fuel lter

removes contaminants from diesel fuel before it ows

into the injection pump where it is injected into the

engine combustion chamber.

The radiator mounted in front of the engine cools the

engine. As coolant ows through the radiator, airow

from the engine-driven fan removes heat.

Refer to the Engine Operator’s Manual accompanying

your paver for additional engine information.

Track SystemTrack System

The paver drive system contains two heavy-duty torque

hubs that propel the hydrostatically-powered, self-

cleaning tracks with self-adjusting front idlers. Two-

speed motors power tough planetary drives for smooth

operation.

Components Overview

This section describes the major components for the

LeeBoy 8515E Conveyor Paver. Become familiar with

these components before operating the machine.

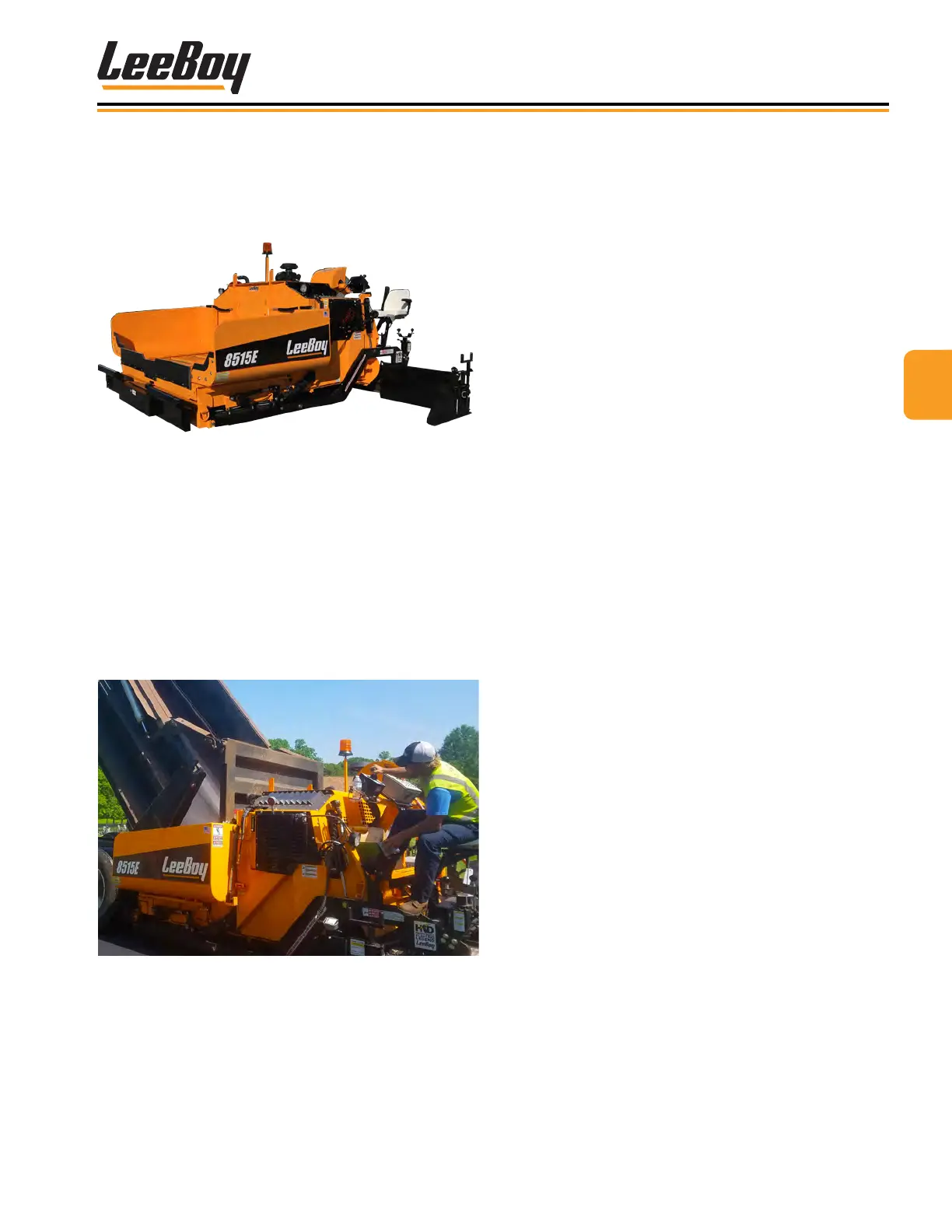

Dual Operator PlatformsDual Operator Platforms

The dual operator platforms allow easy and convenient

access for controls of most paver functions. The paver

can be operated from the left or right side, depending

upon which control panel side is active and best suited

to the working conditions. The control panel slides to

either side. Controls can also be lowered to operate

as a low deck or the high deck option with an assistant

standing on the screed walkboard.

Loading...

Loading...