4-32 LeeBoy 8515E Conveyor Paver

Operation

8. Shut down the engine.

9. Secure paver to transport using the following tie-

down procedures.

Tie-Down ProcedureTie-Down Procedure

1. Position paver in center of the trailer.

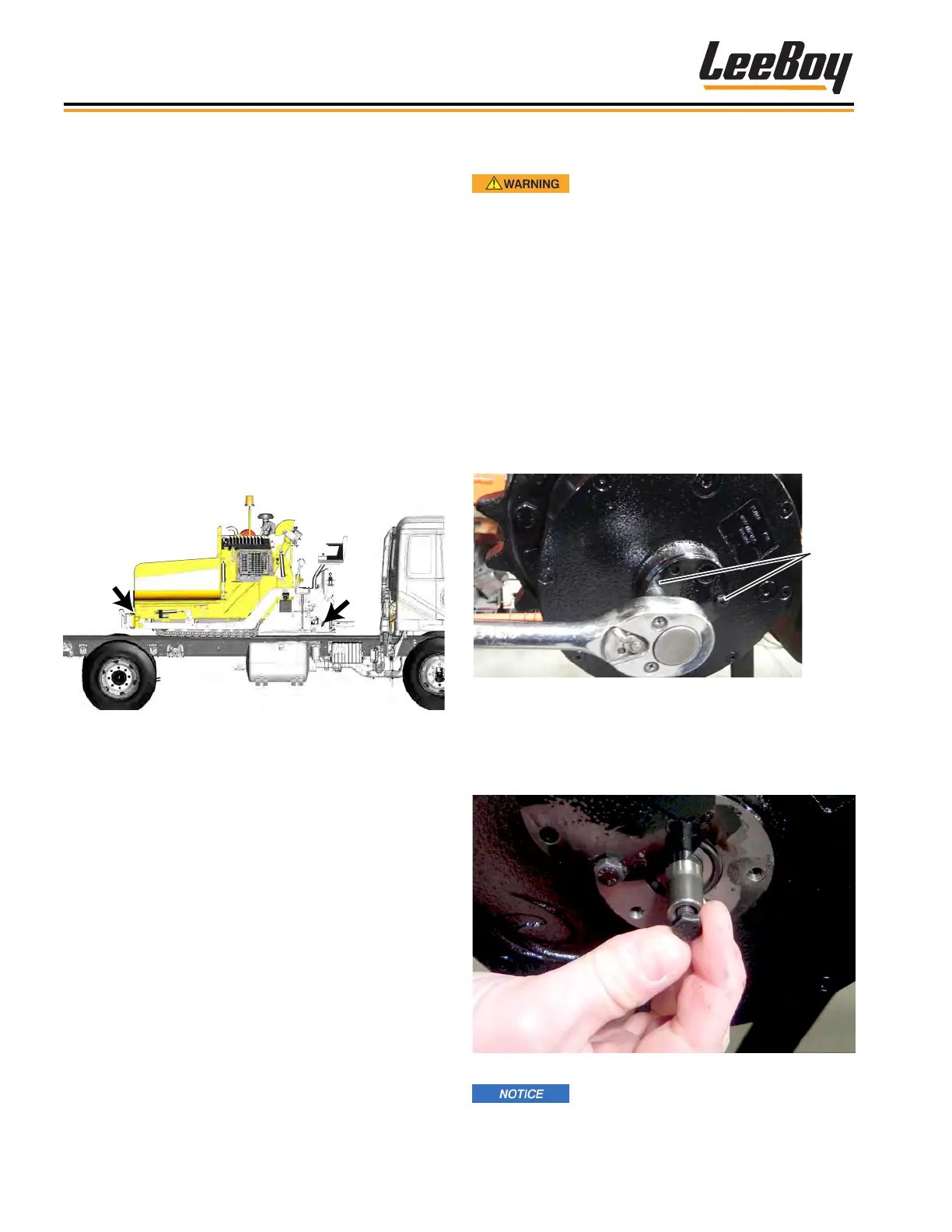

2. Attach tie-down chains to the front weight block

and the D-Rings in front of the torque hubs. (Figure

4-64).

3. Place chocks at wheels or tracks.

4. Attach tie-down chains to rear truck bed and the

paver D-Rings on main screed.

5. Ensure that all chains are tightly secured before

transporting the paver.

D-Ring

D-Ring

Figure 4-64. Tie-Down D-Ring Locations

Towing

Ensure the paver is on level ground

and blocked to prevent machine from moving while

preparing for towing. Be especially careful after

disconnecting the torque hub as the paver could roll.

While it is strongly recommended that the paver be

transported rather than towed, there are situations

where you may need to tow the paver off the road until

a transport vehicle arrives. Do not tow paver long

distances.

You must disconnect the torque hub to prepare the

machine for towing as follows:

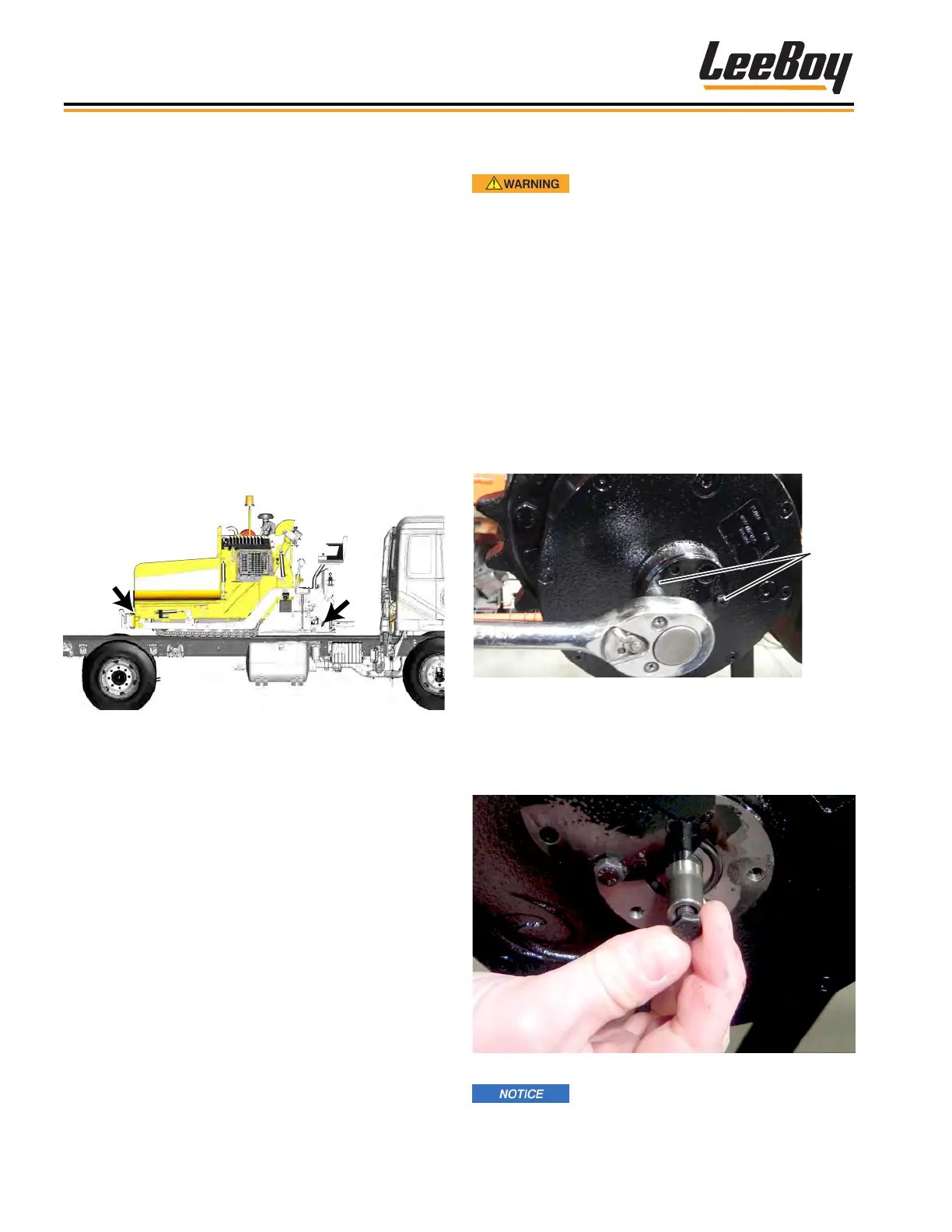

1. Using a wrench, loosen one of the two bolts on the

torque hub cap, then remove the other bolt and

retain for next step. (Figure 4-65)

Bolts

Figure 4-65. Remove Cap Bolts

2. Slide cap over and insert retained bolt into the

center of the hub. (Figure 4-66) This allows you to

pull the release mechanism out, which disconnects

the torque hub.

Figure 4-66. Insert Bolt Into Hub

Be sure to push release mechanism

back into place and reinstall/tighten bolts on cap

when nished moving the paver.

Loading...

Loading...