4-22 LeeBoy 8515E Conveyor Paver

Operation

Once the heating function has been enabled, the dis-

tribution/control box will apply electrical power to the

heating elements and the heating cycle will begin. The

heating cycle is timed to optimize the heat generated at

the screed plates.

NOTE: Allow the screed (and screed extension) to

heat 15 minutes before beginning to pave.

Lower the screed two inches off the ground

while heating to prevent cold air and wind

from affecting the heating process.

Overheating the screed can warp the

screed plate and possibly cause damage. If screed

extensions lock, allow the machine to cool before

attempting to extend or retract. Replace a warped

screed plate immediately.

To operate the electric screed heating system:

1. Start the paver and idle until the engine reaches

normal operating temperature.

2. Raise the screed plate one or two inches off the

ground.

3. Turn the electric heat control box power on.

• Push the switch UP to select MANUAL screed

heat operation.

• Push the switch DOWN to select AUTO screed

heat operation (if equipped with the Automatic

Temperature Control option).

4. Set the throttle on the PV480 display to PAVE (1800

RPMs). Do not exceed 1800 RPMs.

5. Press the Start Heat button.

• The HEAT ON indicator light will illuminate and

stay on as long as the element is heating the

screed. The left light illuminates when the left

screed elements are heating; the right light

illuminates when the right screed elements are

heating.

• While joysticks are in neutral, both sides of the

screed are heating.

• When joysticks are out of neutral, the elements

automatically cycle every two minutes from side

to side to decrease the load to half.

6. If the heat cycle has completed but the screed

plates still require heating, restart the cycle by

repeating Step 5.

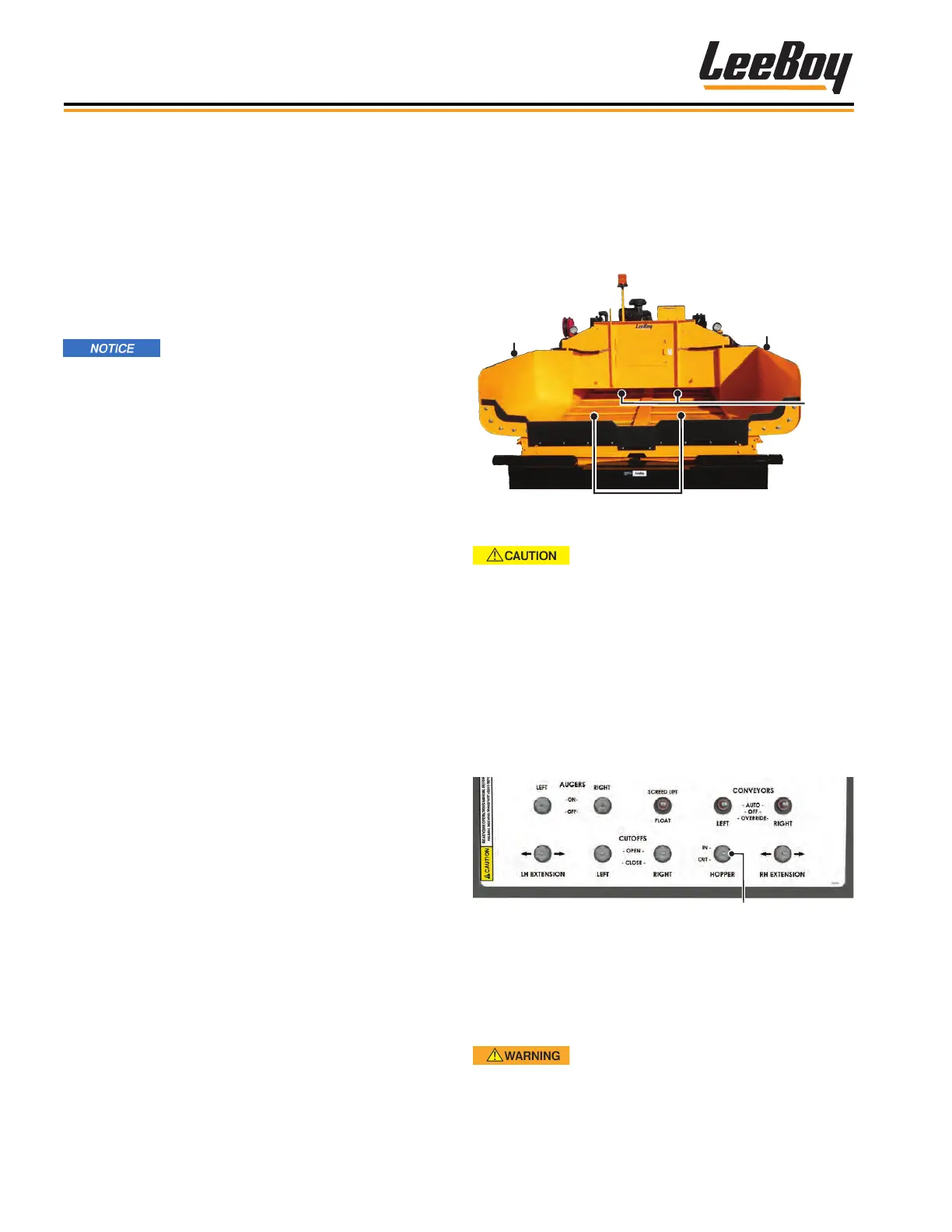

Hopper WingsHopper Wings

The hopper wings are hydraulically opened so the

hopper can be lled with paving material. (Figure 4-42)

Conveyors move the asphalt back to the auger, where

the mix ows through the Under Auger Cut-Offs to the

screed.

Augers

Right

Hopper Wing

Conveyors

Left

Hopper Wing

Figure 4-42. Hopper

Be sure the hopper wings are

unlocked before opening (or closing when in use).

To operate the hopper wings:

1. Ensure the hopper cylinder lock valves, one on each

side of the hopper wings, are unlocked. (Figure

4-44)

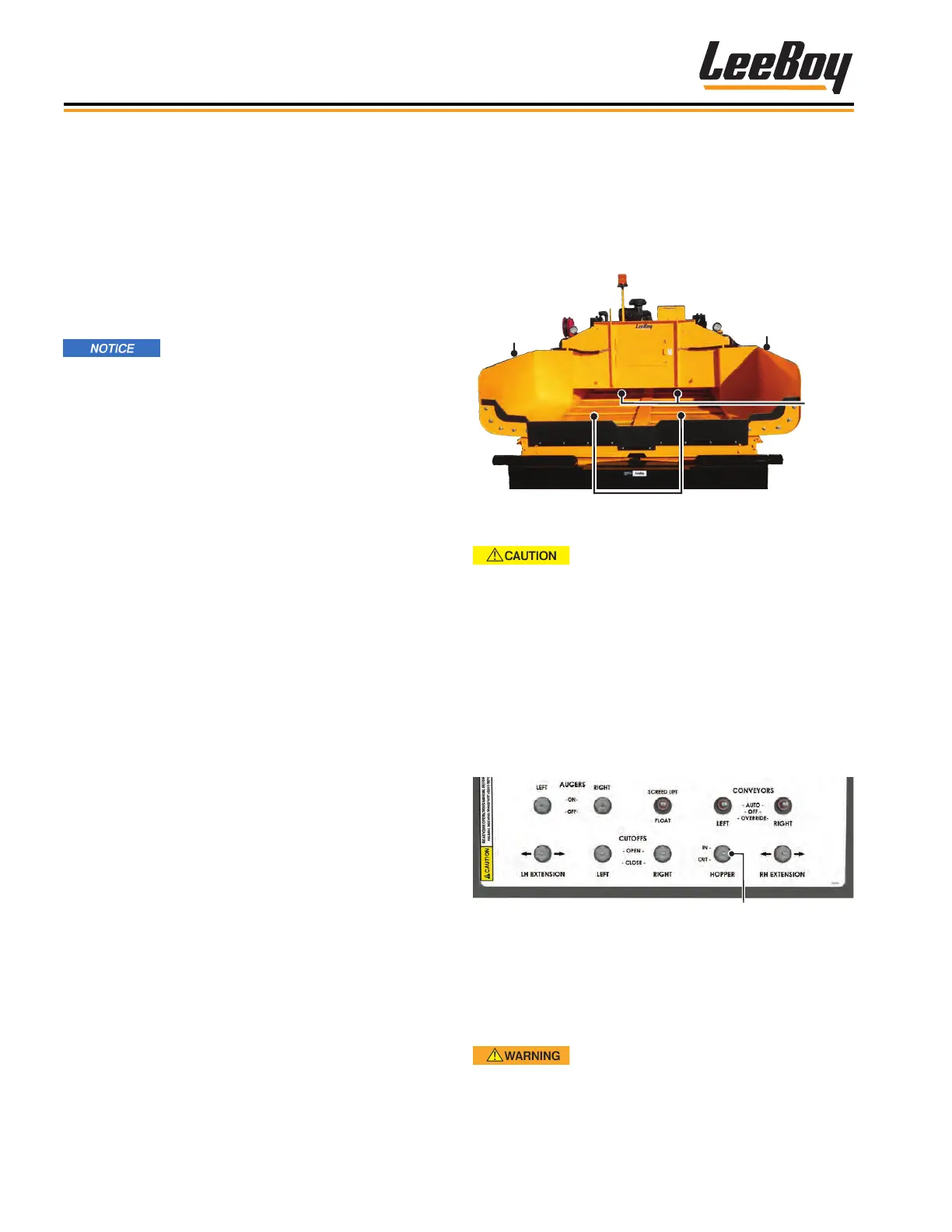

2. Push and hold the hopper wings switch OUT on the

operator control panel to open the hopper wings.

(Figure 4-43)

Hopper Switch

Figure 4-43. Hopper Switch

3. Ensure the hopper wings are completely extended

before receiving paving material from the truck.

4. Push the hopper wings switch to IN to close the

hopper wings.

DO NOT close the hopper wings when

the hopper is full of asphalt. DO NOT close the

hopper until the material truck has moved

completely away from the paver. NEVER raise the

conveyor bed with asphalt in the hopper.

Loading...

Loading...